Rotary Kiln Calcined Bauxite 86 Made in China for Refractory with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DESCRIPTION

QUIKE DETAILS

| Place of Origin: | Shanxi, China (Mainland) | Shape: | Block , Powder | Material: | Bauxite |

| SiO2 Content (%): | 8% Max | Al2O3 Content (%): | 86%Min | Fe2O3 Content (%): | 2%Max |

| CaO Content (%): | CaO+MgO<0.6 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | International standard |

| SiC Content (%): | International standard | Model Number: | Rotary Kiln Bauxite86 | Brand Name: | CNBM |

PACKAGING & DELIVERY

| Packaging Details: | JUMBO BAGS/WOVEN BAGS/ PAPER BAGS (pallets) or as per customers' request! |

| Delivery Detail: | 25 days after buyer's instruction. |

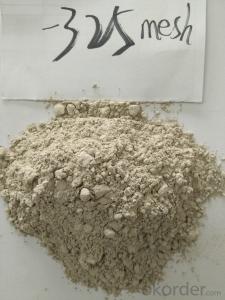

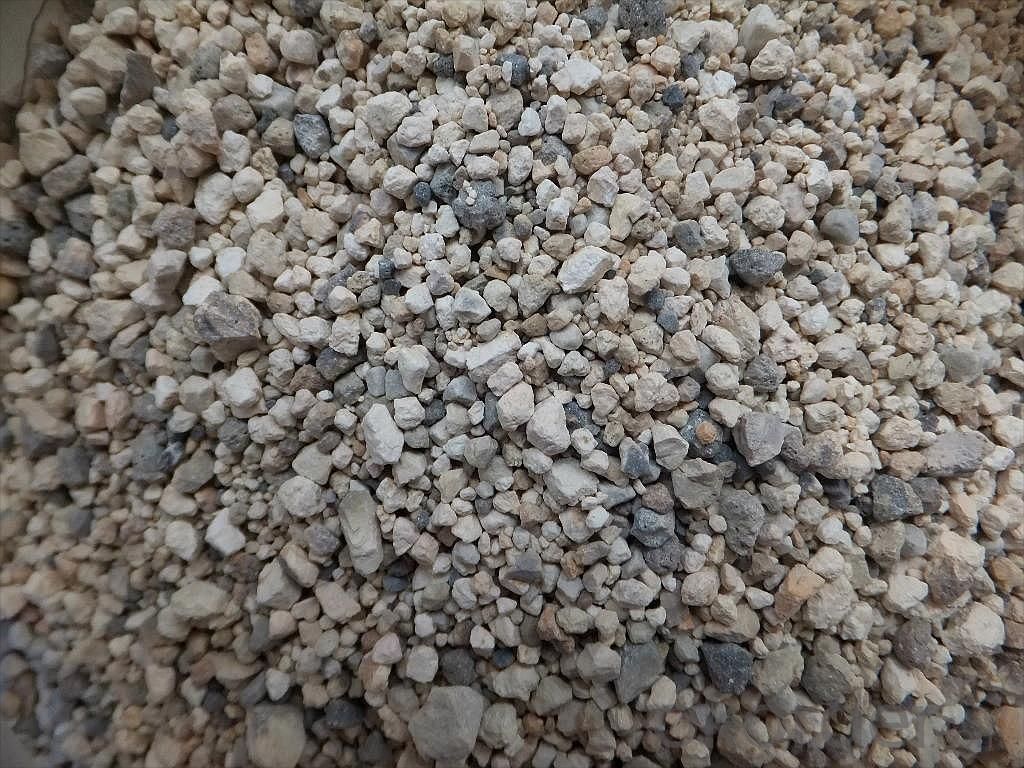

SIZES

| GRAIN | normaly 0-1/1-3/3-5mm,or as per customers' request |

| POWDER | -200/-220/-325mesh,or as per customers' request |

OTHER GRADES OF RKB

GRADE | CHEMICAL CONTENT,% | PHYCICAL PROPERTIES | |||||

Al2O3,% | Fe2O3,% | TiO2,% | CaO+MgO,% | R2O,% | DENSITY, g/cm3 | WATER ABSORPTION,% | |

GAL-70 | ≥70 | ≤2.0 | - | ≤0.6 | ≤0.6 | ≥2.75 | ≤5.0 |

GAL-80 | ≥80 | ≤2.0 | ≤4.0 | ≤0.5 | ≤0.5 | ≥2.90 | ≤5.0 |

GAL-85 | ≥85 | ≤1.8 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.10 | ≤4.0 |

GAL-88 | ≥88 | ≤1.5 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.15 | ≤4.0 |

GAL-88HG | ≥88 | ≤1.5 | ≤4.0 | ≤0.4 | ≤0.4 | ≥3.25 | - |

And we can accept other grades as customer's request.

PICTURES

COMPANY PROFILE

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

Since 2004, the trading volume of CNBM International has been doubled in 5 successive years owing to the support of superior corporations and effort of all staff. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target.

In line with the business, CNBM International launched E-business platform Okorder.com.

Our goal is to transform CNBM International into the global leading brand in building materials industry within 3 to 5 years through innovation and reform, by strengthening the overall management of supply chain, developing and cultivating both domestic and overseas market, improving the procedure and information system, enhancing the ability to organize resources and to provide value-added services under a professional team and a learning organization.

With the advantages in Cement, Composite Materials, New Building Materials and Engineering, we mainly concentrate on coal, steel and construction equipments and give priority to solar and wind energy development simultaneously utilizing our competitive position on traditional building materials to achieve sales revenue of RMB10 Billion in 2013.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

On July 7th, the US Fortune magazine published the 2014 Ranking List of World Top 500 Enterprises. China National Building Materials Group Corporation (CNBM Group in short) enters into the Fortune Global 500 for the fourth successive time with its operating revenue of 41.03 billion USD, ranking the 267th place, and rising 52 places over last year. Amongst the three building materials enterprises listed in the Fortune Global 500, CNBM ranks the second with promising momentum.

The rapid development of CNBM Group derives from the market-oriented reform of diversified ownership and a series of innovative actions carrying forward the industrial reorganization. Thanks to the exploration into the marketization mode of SOK enterprises (state-owned keyenterprises), CNBM Group reorganized almost a thousand enterprises with limited government capital and hence reactivated a greater amount of social capital, which exerted a positive influence on building material industrial transformation and achieved a win-win situation between China’s national assets appreciation and enterprises development. Now CNBM Group has become a remarkable example in SOK enterprises’ diversified ownership reformation

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q:Detailed description of magnesia dolomite refractory material?

- In the cement kiln firing zone, the f-CaO in the dolomite material is easily combined with the C2S in the clinker to form C3S, so the kiln cover can be easily hung, and the kiln crust and the refractory brick are firmly combined and easy to maintain.

- Q:What brands are the best in the A-level refractory materials?

- 1 International (It is a well-known brand in the field of global boats and protective coatings, the products are famous for its safety, strength and smoothness, Akzo Nobel (China) Investment Co., Ltd.) 2 LANLING (It is a high-tech enterprise, and a large provider of industrial coatings, started in 1980, as well as a famous brand of Jiangsu Province, Jiangsu Lanling Chemical Group Co., Ltd.) 3 Champion (It is a high-tech enterprise who is involved in developing a number of industry standards, it is a industry-leading brand brand of Jiangsu Province Jiangsu champion coating Technology Group Limited)

- Q:What is the fire endurance of ceramsite concrete blocks?

- What is mentioned in fire?safety?rules is that the fire endurance of 240mm thick hollow brick of ceramsite concrete is 2.9h, so 190mm thick hollow brick is 3h. B05 thickness(mm), fire endurance(h). Combustion performance 100 4.0. Non-combustible component 150 6.0200 8.0300 〉8.0B06 100 〉4.0150 〉6.0200 〉8.0300〉8.0: The fire endurance performance of building blocks wall in the table is taken from the Tianjin Construction Standard "light steam pressing aerated?concrete?block" DB / T29-128.

- Q:Does hardware construction materials contain refractory?

- refractory includes one kind of building materials. It is a special material and not commonly used.

- Q:Who knows about the criteria of fireproof and thermal insulation materials?

- The standards of fireproof and thermal insulation material. 1. the height of buildings is greater than or equal to 100 m, the combustion performance of thermal insulation materials should be A-level; 2. the height of buildings is greater than or equal 60 m but less than 100 m, the combustion performance of thermal insulation materials should be no less than B2-level. When using B2-level thermal insulation materials, fire barrier zone should be set in each floor; 3. the height of buildings is greater than or equal to 24 m but less than 60 m, the combustion performance of thermal insulation materials should be no less than B2-level. When using B2-level thermal insulation materials, fire barrier zone should be set in every two floors; 4, the height of buildings is less than 24 m, the combustion performance of thermal insulation materials should be no less than B2-level. When using B2-level thermal insulation materials, fire barrier zone should be set in every three floors.

- Q:Does anyone know fire-proof material of fireproof wooden door?

- Fireproof wooden door goes through the flame treatment, so it can prevent fire. Its principle: Fire-retardant treated timber has become flame retardant material itself and its fire endurance has increased. The commonly used method of fire retardant treatment for timber including: Spraying method, soaking method, boiling method, vacuum method, vacuum-pressure method.

- Q:Who knows the classifications of magnesia refractory?

- They can be devided into two major categories of fettling magnesite grain and magnesite products. They can be divided into fettling magnesite grain, magnesia?brick, magnesia-silica brick, magnesia-alumina brick, magnesium-calcium brick, magnesia-carbon brick and other varieties according to the chemical compositions and purposes Its performance is greatly affected by CaO / SiO2 ratio and impurities. The load softening point and thermal shock resistance of high purity magnesia brick are much higher than those of the general magnesia bricks. It has high refractoriness and good resistance for alkaline slag and iron slag, which is an important kind of advanced refractory material. Magnesia products are mainly produced by sintering, and sintering temperature is generally between 1500 ~ 1800 ℃. Besides, chemical binder can be added to make unburned?bricks and unshaped refractories. Mainly used in open hearth furnace, electric furnace, oxidation converter, non-ferrous metal metallurgy furnace, cement kiln and calcining kiln for basic refractory.

- Q:Which region use more refractory?

- You can read some relevant statistical material and east China uses refractory the most.

- Q:What's the fireproof specification for constrcution external wall thermal insulation materials?

- incombustible material: Class A1 (homogenous): such as YT inorganic active insulation material for wall thermal, foam glass, rock(ORE) wool, glass wool, insulation?board of aerogel,expanded perlite series, expaned glazed hollow bead, foam insulation boards, ETC. Class A2 (non-homogeneous composite): such as phenolic foam, gelatine powder polyphenyl granule thermal insulation material, inorganic coating materials and other nonflammable material. phenolic foam insulation board, urea resin foam and board, high flame-retardant polyurethane rigid foam and board, high flame retardant polystyrene cystosepiment, gelatine powder polyphenyl granule heat insulating slurry and other combustible?materials. Requirements for combustion levels of common antiflaming EPS, common inflaming retarding XPS, common antiflaming rigid PU foam board: Class A is incombustible?material (product); B1 nonflammable material (product); B2 combustible?material (product); B3 combustible material (product).

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rotary Kiln Calcined Bauxite 86 Made in China for Refractory with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords