Room Heating System XPS Tile Backer Board Underfloor Heating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Decription of XPS Tile Backer Board Underfloor Heating:

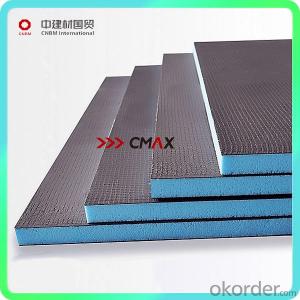

CNBM heat insulation boards are manufactured using a high-density and waterproof extruded polystyrene core(XPS) with a polymer modified, glass fibre reinforced cement coating on both sides, which adds rigidity and strength to the board and shower trays.

Applications of XPS Tile Backer Board Underfloor Heating:

1.Wall and floor insulation for interior and exterior.

2.Underfloor heating

3.Waterproof and insulating projects for wet areas such as bathroom, kitchen, swimming pool,spa.

4.Enclosures for bathtubs, columns, steps and water pipes.

Sizes available of XPS Tile Backer Board Underfloor Heating:

| Standard dimensions and weight | |||

| Short board | Thickness(mm) | Weight(kg/m²) | Length *width(mm*mm) |

| 6 | 2.7 | 1200*600 | |

| 1220*600 | |||

| 1250*600 | |||

| 10 | 3.1 | 1200*600 | |

| 1220*600 | |||

| 1250*600 | |||

| 12 | 3.2 | 1200*600 | |

| 1220*600 | |||

| 1250*600 | |||

| 20 | 3.5 | 1200*600 | |

| 1220*600 | |||

| 1250*600 | |||

| 30 | 3.8 | 1200*600 | |

| 1220*600 | |||

| 1250*600 | |||

| 50 | 4.3 | 1200*600 | |

| 1220*600 | |||

| 1250*600 | |||

| Standard dimensions and weight | |||

| Long board | Thickness(mm) | Weight(kg/m²) | Length *width(mm*mm) |

| 6 | 2.7 | 2440*600 | |

| 2500*600 | |||

| 10 | 3.1 | 2440*600 | |

| 2500*600 | |||

| 12 | 3.2 | 2440*600 | |

| 2500*600 | |||

| 20 | 3.5 | 2440*600 | |

| 2500*600 | |||

| 30 | 3.8 | 2440*600 | |

| 2500*600 | |||

| 50 | 4.3 | 2440*600 | |

| 2500*600 | |||

Customized sizes and package can be provided as well.

The thickness is not than 80mm

The Width is not than 1200mm

Reaction to Fire of XPS Tile Backer Board Underfloor Heating:

The boards are classified as class E according to EN 13501-1. When the boards are covered with tiles, their fire performance should comply with local construction laws and regulations.

Effect on indoor environment of XPS Tile Backer Board Underfloor Heating:

CMAX board has been assessed as not emitting any particles, gases or radiation that may have a negative effect on the indoor climate or to have any significant effect on health.

Environmental declaration of XPS Tile Backer Board Underfloor Heating:

The product does not contain any substances on the observation list of dangerous substances published by the national environmental authorities.

Main applications of XPS Tile Backer Board Underfloor Heating:

Used as a watertight layer on walls and floors in houses, hotels and other wet areas such as bathroom, shower room.

Other applications of XPS Tile Backer Board Underfloor Heating:

Other places to be insulated and waterproofed.

Applications:

1. as a watertight layer on walls and floors in wet rooms and bathrooms.

2. as an insulation layer in under floor heating to avoid heat loss.

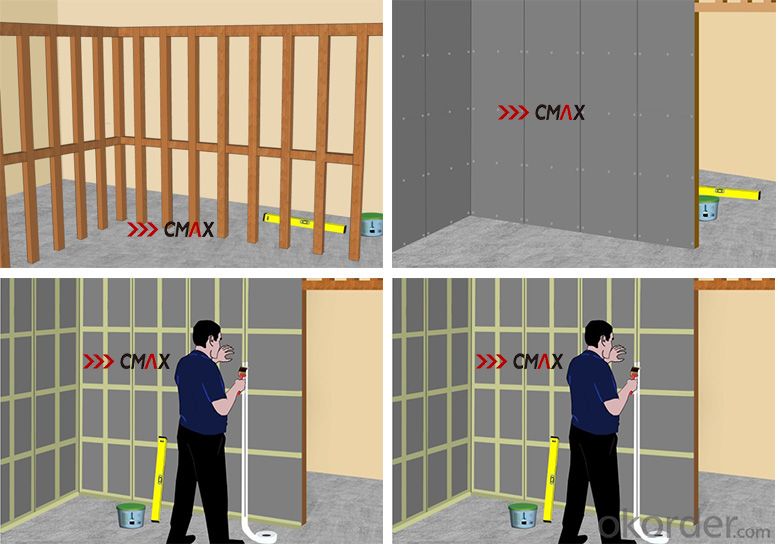

3. as partition walls in wood or steel frames.

4. substitute for gypsum board and fiber cement board; insulation and waterproofing; lighter so that more easily to install.

5. As enclosures for bathtubs, water pipes, etc.

6,Can very easily and fast formed to be small shelves, washbasins, shower benches and soap boxes.

7. Combining with CMAX curved/shapeable boards, kinds of decorative models can be made with your infinite creativity.

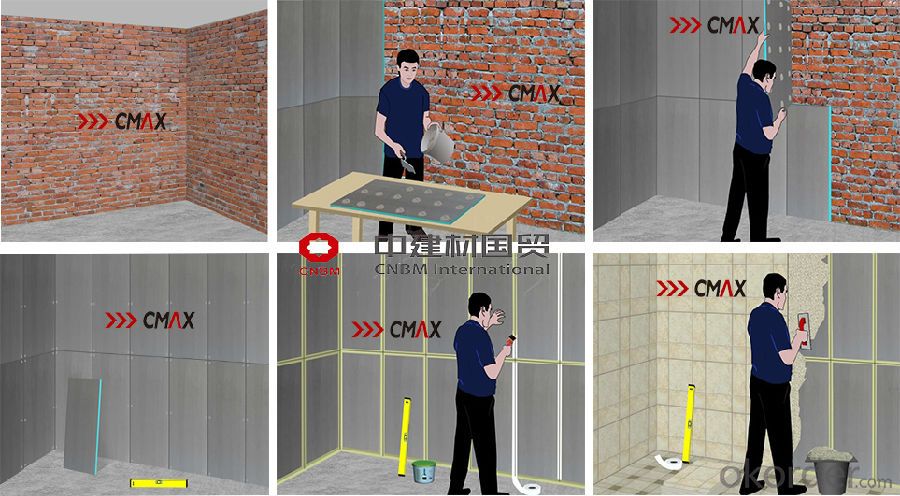

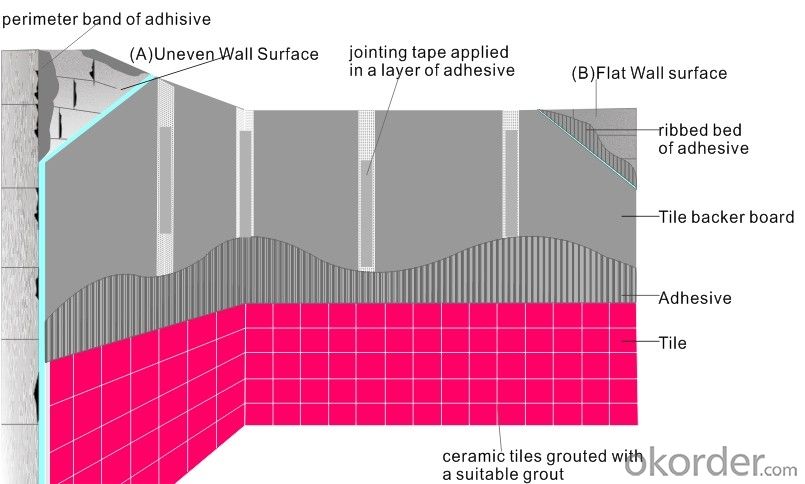

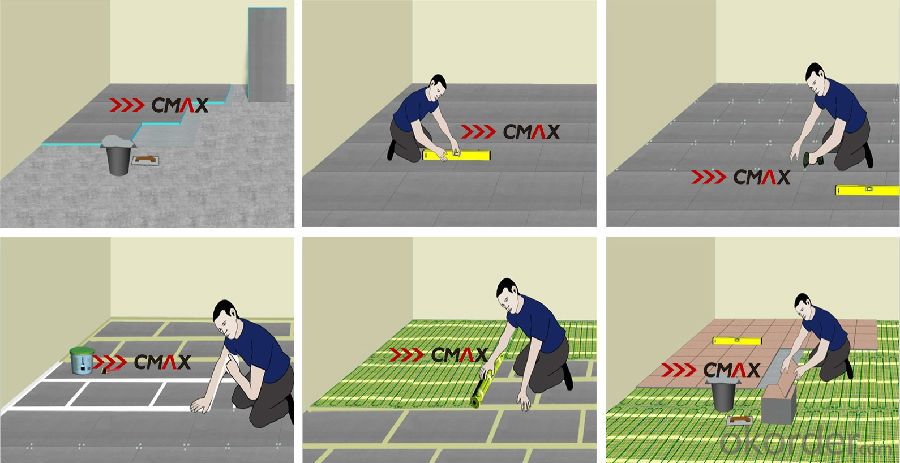

Fixing:

Choose a way to fix CMAX board according to the substrate to be fixed. Normally, using modified tile adhesive for solid concrete wall/floor and strengthened by mechanical fixings when necessary while only using mechanical fixings for wood and steel frames.

Reinforcement:

1. Dry areas: reinforce all joints between boards, floors and walls by 125px or 250px wide self-adhesive tape.

2. Wet areas: reinforce by suitable waterproof tape.

Waterproof strengthen:

1. Strengthening all joints between boards, floors, walls and mechanical fixings placements by suitable waterproof tape.

2. Strengthening joints between walls, outside corners and inside corners by special corners.

3. Sealing pipe holes with special waterproof tape.

4. Strengthening once again by waterproof glue, liquid tanking membrane, tanking membrane paint, etc. when necessary.

Coating of panels:

Should always be covered by ceramic tiles, mosaics or other equivalent non-fireproof materials after installation.

FAQ:

1.

Q: Are you a manufacturer of insulation materials?

A: Yes. ourselves manufacturer of thermal insulation board.

2.

Q: What is the seaport near your plants?

A: The nearest port is Shanghai Port, there are about 100km from the port to our plant in Shanghai.

3.

Q: What is annual production capacity of your main products?

A: 200,000 piecs per month.

4.

Q: Do you have your own brands? And what are they.

A: Yes. we are a fortune 500 company, our brand is "CMAX"

5.

Q: Is sample available for testing?

A: Yes. The sample is free.

We do OEM as well. Welcome to make an enquiry and we will give you quick response in 12 hours!

- Q:How is the flame and combustible defined by the naked eye? I burn the B1 level and B2 level XPS board is different? Question added: detection time is longer, can quickly and intuitively identified? More

- Air-conditioned room can not have flammable gas, in order to avoid explosion and fire do not frequent switch air conditioner, because the compressor starts when the current is running a lot of times the current, easy to burn the compressor motor 3) Do not put things on the outdoor unit of the air conditioner to avoid air conditioning noise. It is a great persecution for the air conditioner. The temperature of the general air conditioner is adjusted to 26 ° C to 28 ° C. , To avoid excessive power consumption next to the air conditioner must not be twitching Fengqi gong bite astringent ax to have a high temperature heat source, so as not to heat the panel deformation

- Q:What is the difference between an extruded board and an XPS extruded board?

- What is the form of this, and you want to be on the scene to be helmet helmet helmet gnome insects rhinoceros kitery to be set. But single, double row scaffolding with a high degree of single-row scaffolding should not exceed 24M, double row scaffolding erection height can not exceed 50 meters, more than 50 meters high double scaffolding should be double pipe, sub-unloading, sub-erection and other measures The "Technical Specification for Safety of Fastener Steel Scaffolding" JGJ130-2011

- Q:Steel structure rock wool sandwich wall panel what the amount of this set

- Generally in the 100-300 yuan / cubic or so, 60 mm thick is 6-18 yuan / square or so Specifically look at how much you use the density of the Polystyrene foam board - also known as foam board, EPS board is made of volatile liquid blowing agent containing polystyrene beads, heated by the preheated in the mold after heating the formation of white objects, its fine The structure of the obturator is mainly used for building wall, roof insulation, composite board insulation, cold storage, air conditioning, vehicle, ship insulation, floor heating, widely

- Q:The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- In when Edison in the study of incandescent bulbs, in the white hot filament inserted between a metal sheet

- Q:I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- Think of the safety data directory to compare the trouble to compare JGJ59-2011 check the information bar

- Q:What is the difference between extruded polystyrene board and XPS insulation board?

- The interior design of the ceiling, to determine the location of the tuyere, and then design the HVAC professional with the design, after the design, you will find some outlet can not be arranged, or the ceiling must increase the outlet, and then install the factory twisted class defended straight gambling astringent leopard Adjusting the ceiling to adjust the drawings. In other words, this is the process of two professional cooperation with each other, but mainly based on the decoration ceiling map.

- Q:Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- The key depends on your choice of waterproof construction and product quality, we recommend you choose Dongfang Yuhong waterproof products and standardized construction team, the East Rainbow is the best quality waterproof listed enterprises RPUF-371 sprayed foam polyurethane waterproof insulation integrated system " Rainbow "spray foam polyurethane waterproof insulation integrated system is composed of rigid foam polyurethane foam waterproof insulation integrated material and the protection of the surface layer composition

- Q:Sound insulation and polystyrene insulation board which sound insulation better?

- The best bamboo pole, or plastic, aluminum alloy, then there is no child at home can have a child, then it is dangerous to fall easily hit people

- Q:Polystyrene foam hard insulation board will not be harmful to the human body, right?

- Building safety production management issues, please choose the answer (multiple choice)

- Q:Why extruded board (XPS board) is the best insulation board material

- Scaffolding from the erection of the main points on the scaffolding, cantilevered scaffolding and climbing three. High-level general use of floor and cantilever set of set enough to set the dumplings rush to set off the boat to Long. If the number of layers to more than 30F, and the structure can be relatively simple climbing scaffolding, climbing the advantage of the higher the height of the higher relative to the cost of picking. I am a professional scaffolding company, do not understand can ask me. I hope I can help you.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Room Heating System XPS Tile Backer Board Underfloor Heating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords