Roofing Ceiling Decorative Alloy Coated Color Prepainted Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Roofing Ceiling Decorative Alloy Coated Color Prepainted Aluminum Coil

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Roofing Ceiling Decorative Alloy Coated Color Prepainted Aluminum Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Roofing Ceiling Decorative Alloy Coated Color Prepainted Aluminum Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

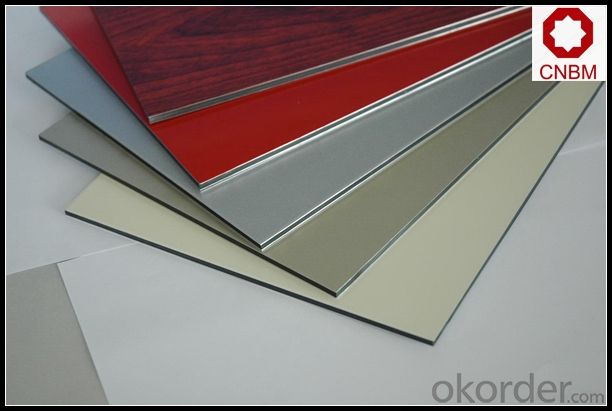

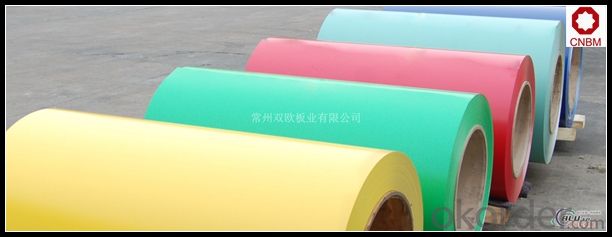

5. Image of Roofing Ceiling Decorative Alloy Coated Color Prepainted Aluminum Coil

6. Package and shipping of Roofing Ceiling Decorative Alloy Coated Color Prepainted Aluminum Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can the little can opening cap things on an aluminum can be recycled? My friend told me if you fill a two liter bottle with them you can get loads of cash. Is this true?

- Yes. Aluminium can be recycled. (watch the TV ad, UK) No. You would need tons of the stuff ( a tonne of copper is only around ?1000) They are usually colleced for charity. And they save up all the 2 litre bottles full! Feel the weight, aluminium is very light.

- Q:What are the potential fire hazards associated with aluminum coils?

- There are several potential fire hazards associated with aluminum coils. First and foremost, aluminum is a highly flammable material, which means it can catch fire easily and burn quickly. This poses a significant risk if there is an ignition source nearby, such as an open flame, electrical spark, or hot surface. Another potential fire hazard is the accumulation of dust, dirt, or other combustible materials on the aluminum coils. These substances can act as fuel for a fire, increasing the likelihood and intensity of combustion. It is important to regularly clean and maintain the coils to prevent the buildup of such materials. Aluminum coils are often used in HVAC systems, and if these coils are not properly installed or maintained, they can become a fire hazard. For instance, if the coils are not securely fastened or if there are loose electrical connections, it can lead to overheating and potentially cause a fire. Additionally, aluminum coils can cause electrical fires if they come into contact with live electrical wires or if there is a short circuit. This can happen if the coils are installed too close to electrical components or if there is a failure in the insulation or grounding of the system. Lastly, the use of flammable refrigerants in HVAC systems can also increase the fire risk associated with aluminum coils. If there is a leak or malfunction in the refrigerant system, it can create a flammable atmosphere around the coils, leading to a potential fire or explosion. To mitigate these fire hazards, it is crucial to follow proper installation guidelines, regularly inspect and maintain the coils, keep the surrounding area clean and free from combustible materials, and ensure that there are no electrical or refrigerant leaks in the system. It is also recommended to have fire detection and suppression systems in place to quickly respond to any potential fire emergencies.

- Q:What are the potential applications of patterned aluminum coils?

- Patterned aluminum coils have a wide range of potential applications in various industries. They can be used for decorative purposes in architecture and interior design, such as wall cladding, ceilings, and facades. Additionally, they are commonly utilized in the automotive industry for decorative trims, grilles, and exterior body parts. The patterned coils can also be used in the manufacturing of household appliances, furniture, and electronics, providing aesthetic enhancements and durability. Furthermore, they have potential applications in packaging, signage, and advertising, as well as in the production of heat exchangers and radiators. Overall, the applications of patterned aluminum coils are diverse and offer a versatile solution for both functional and decorative purposes.

- Q:I know aluminum has gone up in price. I know very little about gutter material. Durability, leaf guards, etc. I am on a limited income, and need the most and best for my few bucks. Thanks Lee

- aluminum is the best for you. plastic is junk

- Q:Guangdong where there are professional to do around the paper corner, is packing steel coil, aluminium coil that protect the edge of the both ends of the cylinder. Just the kind of picture.

- Guangdong Province, professional Foshan recommended edgeboard around Foshan Ansheng packaging. They are very professional in their circle, L shaped, and curved corners.

- Q:Automotive aluminum coil, using GB H22, what brand, what are the main ingredients?

- 5754-H22 aluminum sheet has the characteristics of medium strength, good corrosion resistance, weldability and easy processing. It is a typical alloy in Al-Mg (mg Al alloy) alloy. In the corresponding foreign brands for AlMg3, 5754 different heat treatment is the automobile manufacturing industry (car door, mould, seals), main materials used for canning industry

- Q:What are the different surface finishes for pre-painted aluminum coils?

- Pre-painted aluminum coils offer a variety of surface finishes to enhance their appearance, durability, and resistance to external factors. The most commonly used finish is Polyester (PE), which provides good durability, weather resistance, and color retention. It is available in a wide range of colors and gloss levels. Another popular option is Polyvinylidene Fluoride (PVDF) finish, known for its excellent resistance to weathering, UV radiation, and chemicals. It maintains color and gloss for extended periods, making it ideal for architectural applications. Polyurethane (PU) finish is preferred for its resistance to abrasion, chemicals, and weathering. It offers a smooth and glossy appearance and is available in various colors. PU finish is commonly used in outdoor applications that require high durability. Epoxy (EP) finish is known for its excellent chemical resistance and adhesion. It is often used in industrial applications where corrosion resistance is crucial. It can be combined with other coatings to enhance its performance. Acrylic (AC) finish provides good weather resistance and color retention. It is commonly used in architectural applications where aesthetics and durability are important. Acrylic finish offers a glossy appearance and a wide range of colors. These examples demonstrate the range of surface finishes available for pre-painted aluminum coils. The choice of finish depends on specific requirements, including desired appearance, durability, and resistance to external factors.

- Q:Can aluminum coils be used in the production of aluminum gutters?

- Aluminum gutters can indeed be produced using aluminum coils. In fact, aluminum coils are commonly employed in the manufacturing process of aluminum gutters. These coils are crafted from an aluminum alloy, which happens to be a material that is both lightweight and long-lasting. By utilizing specialized machinery, these coils are expertly molded into the desired gutter profile. The utilization of aluminum coils enables the production of gutters to be efficient and precise, thereby guaranteeing a top-notch final product. Furthermore, aluminum possesses the advantageous quality of being resistant to corrosion, rendering it an ideal material for gutters that will be exposed to various weather elements like rain and snow. All in all, due to their durability, strength, and corrosion resistance, aluminum coils prove to be an excellent choice for the production of aluminum gutters.

- Q:Are aluminum coils easy to bend and shape?

- Yes, aluminum coils are relatively easy to bend and shape. Aluminum is a malleable metal, which means it can be easily deformed under compression without breaking. This property makes it highly suitable for shaping and forming into various shapes and sizes. Additionally, aluminum coils can be manipulated using different techniques such as rolling, bending, or pressing, allowing for a wide range of applications in industries such as construction, automotive, and manufacturing. However, the ease of bending and shaping aluminum coils may also depend on the specific alloy and thickness of the coil. Thicker coils may require more force and specialized equipment for shaping, while certain alloys may have different levels of malleability. Overall, aluminum coils offer a versatile and relatively easy-to-work-with material for bending and shaping purposes.

- Q:Can aluminum coils be used in corrosive gas environments?

- Yes, aluminum coils can be used in corrosive gas environments. Aluminum has a natural oxide layer that provides excellent corrosion resistance, making it suitable for various corrosive environments including those with corrosive gases. However, it is important to consider the specific corrosive gas and its concentration, as certain gases may still have a corrosive effect on aluminum over time.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Roofing Ceiling Decorative Alloy Coated Color Prepainted Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords