Roller Shutter Forming Machine with ISO Quality System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

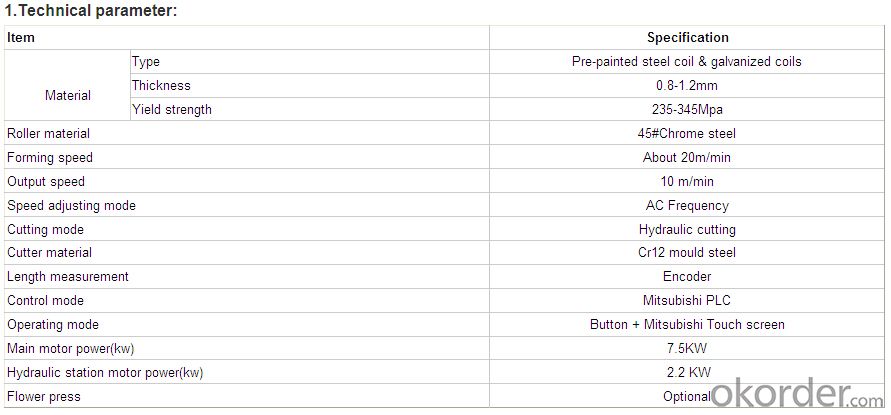

Quick Details

Condition: New

Type: shutter door roll forming machine

Tile Type: Steel

Use: shutter door

Production Capacity: 10m / min.

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Zhongyuan

Model Number: ZYYX series

Power(W): 7.5KW

Voltage: can be designed according to buyer's requirement

Dimension(L*W*H): 7000X1000x1400MM

Weight: 3500KG

Certification: CE, CE ISO SGS

Warranty: 12 months limited warranty starting from date of delivery

After-sales Service Provided: Engineers available to service machinery overseas

Quality system: ISO9001

Controller system: Mitsubishi PLC

Cutter material: CR12 mould steel, quenched treatment

Cutting style: Automatic hydraulic cutting

Roller material: No.45 steel, plated with chrome on suface.

Shaft for rollers: 55mm dia. solid steel pipe

Guarantee term: first year by free, lifetime services.

Operation language: English or as per client's requirement

Hydraulic power: 2.2KW

Packaging & Delivery

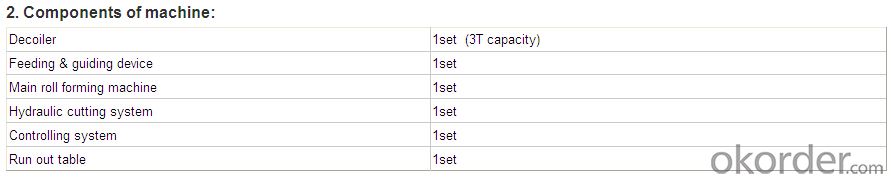

| Packaging Details: | 1. one 20ft container for loading one set of machine with mechanical decoiler; 2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film; 3. Spare parts and some small parts packed in plastic tooling box; 4. All Components Fixed by steel wire with Container. |

|---|---|

| Delivery Detail: | within 50 days |

Why choose this machine?

1.Certificate: ISO 9001, CE,

2. Lifetime services

3. Roller cover with 0.05mm chrome; 55mm diameter solid steel shaft. Lifetime>10years.

4. Introduced Mitsubishi PLC with touch screen to machine controll system.

5. One worker operation (minimum)

6. Heat treatment:Cutting blade. Quenched treatment: Cr12 mould steel cutter

7. Product cut-to-length.

8.Technician overseas installing and training available

- Q:The difference between CNC machine tools and ordinary machine tools

- The other is all mechanical components, there is no automatic control system.

- Q:What equipment, machine tools, lathes, or other equipment? Probably are a length of not more than 30cm a number of hollow

- check the electrical distribution box should be closed and reliable, good electrical grounding;

- Q:CNC machine tools and general machine tools in the detection of the biggest difference between the machine

- In particular, CNC machine tools are now the general batch accuracy within 0.02MM, is difficult to proportion of ordinary machine!

- Q:How about CNC machine tools

- According to the position of the anti-check side of the components of the installation and the use of the feedback device is different, it is divided into closed-loop control and semi-closed-loop control of two control methods.

- Q:What is the machine?

- Machine is the machine that makes the machine, also known as the machine tool or machine machine, used to be referred to as machine tools.

- Q:CNC lathes 6140 and 6040 What is the difference

- 1 for single-axis automatic lathes, 2 for multi-axis automatic semi-automatic lathes, 3 for hexagonal lathes, 4 for crankshafts and camshaft lathes, 5 for vertical lathes, 6 for lathes,

- Q:Machine operating procedures

- 2, check the machine, workstations, rails and the main sliding surface, such as obstacles, tools, iron, impurities, etc., must be cleaned, wipe clean, oil;

- Q:What is the risk of CNC lathes

- 2, iron dust dust pollution, processing parts will produce some debris;

- Q:What is the difference between CNC machine tools and general machine tools?

- 2, the use of automatic chip removal device CNC lathes are mostly inclined bed structure layout, chip removal convenient, easy to use automatic chip conveyor.

- Q:Say that China's machine is not good, then they are sold to whom?

- With the progress of society and the development of science and technology, the gap between domestic machine tools and imported machine tools will be getting smaller and smaller.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Roller Shutter Forming Machine with ISO Quality System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords