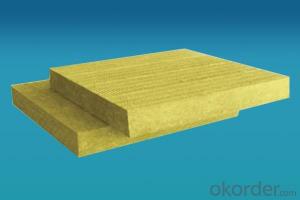

Rock Wool Thermal Insulation Board with Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fireproof Rock Wool Rock Wool Board with High Quality

Introduction

The external thermal insulation rockwool board is designed for the buildings of external thermal insulation system with thin finish coat and applys to external wall insulation and energy saving of new or existing building whose foundation wall is concrete or brick and other compact structures.

The external thermal insulation rockwool strip can also be used as fire barrier to improve the fire resistance of buildings external walls with other thermal insulation materials.

Features and Application

1,High compressive strength, tensile strength and good durability ensures the reliability and long-term stability of the product in the application.

2,Low thermal conductivity can effectively reduce the heat loss of the building to achieve energy saving and emission reduction.

3,External thermal insulation rockwool boards will not release heat and poisonous smoke because of its incombustibility and can effectively partition the spread of flam when fire occurs.

4,It has good performance of non-hygroscopicity, ageing resistance and long-term stability.

5,It is light weight and easy to be cut and processed

Specification

Standard Requirement | Deviation | |

Length | 1200mm | +10/-3mm |

Width | 600mm | +5/-3mm |

Thickness | 30mm—150mm | ±3mm |

Density | 40kg/m3—250kg/m3 | ±10kg/m3 |

Packaging & Shipping

Product is packed in polythene plastic thermal-shrink film.

Thickness of each package is within the range of 300-400 mm.

During transportation and storage, keep product away from moisture and compressive deformation

Genaraly 6-10pcs/pack

- Q:What are some persistent problems that remain to be solved in the field of Civil, Construction, and Environmental Engineering? The answer that I'm looking for can be any basic answer, but I would prefer that it be a fairly technical answer from an experienced person or college student.Anything is welcome though.Thank You.

- At 4.5- 5.5 ghz i would recommend a liquid cooling system- my rating of your specs -10-excellent you can play games at high settings a without a problem,nothing needs to be changed,i mean what do you really think that needs to be change ? again it's a good high end build,nothing more i can say except happy gaming, iguess your os will be windows 7 64 bit

- Q:Types of insulation: Styrofoam, Spray Foam, Fiberglass(for a science project- doing research now)

- styrofoam id the beast practical solution this is the result of my experiance as a civil engineer ang contractor

- Q:My forced air furnace is in the attic and during the 90+ days of summer it seems that my in-wall A/C has to work much more since the furnace blower seems to kick in and blows hot air out of the ventsThe thermostat is set well below the ambient temperature.I am considering having one installed but not really sure if I want it for the correct reason.

- Felting, lanolin, or fabric softener seem to be the main ways it is done, but there are softer wools and also wool overall is pretty scratchySometimes people use a wool blend to make it less-so, but wool is a scratchy yarnFelting helps and sometimes brushing the finished product a little will helpAnother listing suggests washing the wooll in hair conditioner if it is scratchy after dying itThe second site is about wool and more on the softer types of wool one can use.

- Q:I have no one to show me how to knit, so I decided to try and teach myself using videos and tutorials online.I got the hang of it, but when I knit it is really tightI tried going looser, but still tighten upI want to make a scarf, but the tightness makes me question if it is going to get any longer? I use 6 mm needles and the yarn says worsted medium 4 (Yeah, i don't know what that means.)So my question: If I knit tightly, will this scarf get longer?

- It will eventually get longer, no matter what size stitches you makeBut the tighter you knit, the longer it will take and the more yarn it will takeThere are other issues with knitting tightly: 1It tires the hands and can make muscles sore 2It increases tension in the knitter, while knitting is supposed to be a relaxing hobby 3It puts strain on the fibers of the yarn which will effect the stretchiness of the fabric being knit and the life expectancy of the individual fibers in the yarnSo here are some ways to knit less tightly: 1Use a larger needle2Drink a glass of wine (assuming you are of age)3Find someplace quiet to knit4When you start to feel tense, put the knitting down, get up, and walk around5Change the way you tension the yarn around your fingersIf you wrap it around or between too many fingers, you will put too much tension on the yarn which will make the stitches tight Try NOT tensioning around your fingers for a few rowsJust pinch the yarn with your thumb and first finger to wrap it around the right needle for a stitchBetween stitches, let go of the yarn so it can relaxThat will get you a good foundation of a couple of rows of looser stitchesWorking in tight stitches tends to make one tense up because they have to fight to get the needle into the stitch and that tension makes them put a death grip on the yarn, making the next stitches even tighterWhen you have a few looser rows and are ready to tension the yarn again, try putting it over just your forefinger or weaving it over your forefinger, on the palm side of the middle and ring finger, then on the back of the pinkyDo not wind it around any finger, just weave it between themThis will help you keep a looser tensionBe aware it will feel strange because you are used to knitting tightlyIt may be frustrating tooBut stick with it and remember to set the knitting down and take a break when you become frustrated.

- Q:I drank like 3 bottles of Magnesium Citrate in 5 days because i was extremely constipated, along with that i had probably 10 - 15 16oz bottles of water in the course of 2 or 3 days(think i had atleast 1 soda too)now i feel bloated and my side is hurting, the freaky part though is that sometimes when i lay down i feel a cold wetness on my chest but when i touch it it's dry, i've been peeing alot(very very small amounts at a time)what should i do?

- With that amount of water, unless your area is very hot, you should be passing a lot of urine; otherwise sweating a lotIn my area during summer as I drink I perspireFailing that you might be having a bladder or urinary tract infectionThis is usually accompanied by burning (slight or severe) while urinatingNot excreting the excess water can also cause bloating even as constipation wellWhile drinking a lot of water per day is good for the purpose of free bowelBy itself it does not workWater needs to be absorbed by bulk in the intestinal tractThe most effective bulk is water soluble fibers of fruits and vegetablesIf you are eating a very wide variety of fresh fruits and vegetables (approximately 20% fresh fruits and 60% vegetables), you would have no need for any more than Ten, eight ounce (10, 8oz) glasses of water per day to develop a routine of free bowel (one or two actions per day)In this case you would not be resorting to extra Magnesium CitrateIf you are having a urinary tract infection, garlic can help or you might need to see your medical doctor.

- Q:It is my niece's 14th birthday and I want to give her something that is not lameWhat would a 14 yrs old girl love that is not too expensive?

- A computer is a computerThe fact that you are putting your house and these computers in higher regard to your sons health makes me want to scorn you.

- Q:What are the basic or most used materials to produce satellites? (any kind)?

- Alpacas have fabulous wool - very warm, very soft!

- Q:if calories are from carbs but all the carbs are fiber grams does that mean it has 0 calories?

- NoEverything but water and celery (and processed foods that are seemingly calorie free) has caloriesIf all the grams are fiber, it just means that the product was less refined and has more fiber in it than the other comparable productsAll foods we eat (other than fresh or frozen fruit for vegetables) are processed, so you're kind of out of luck thereBasically it just means that your body is going to have an easier time digesting it and will keep you fuller longerDrink water thoughFiber is water soluble, which means it only helps with digestion if you drink waterIf you don't it'll just end up storing as fat.

- Q:I have an enclosed porch above a cold cellar with new windows installed and now want to maximize the rooms comfort with a floor insulationWhat is the better option to insulate the floor?

- Through junk food from your kitchen

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rock Wool Thermal Insulation Board with Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches