Rock Wool Thermal Insulation Board at Competitive Price.

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rock Wool Board

Rockwool felt is produced from molten basalt rocks, spun to fine fibers, slightly bonded with binder formed into flexible rolls. It is also produced by stitching rock fibers with cotton or fiberglass yarns.It can be non-faced or faced with wire mesh.

Rockwool blanket uses high-quality basalt as raw material whose melting point is above 1000 ºC and has good effects on heat insulation and sound absorption.

It has good properties of fire resistance, pest proof, corrosion resistance, stable chemical property and do not contain asbestos. It is green environmental production and do no harm to human bodies

Product Applications:

It can be widely used as thermal insulation material for high-temperature pipe, tank, equipment and vessel in petroleum, chemical and metallurgy industry. It can also be applied to partition, ceiling and building wall as thermal insulation and sound absorption material in construction industry.

1,High compressive strength, tensile strength and good durability ensures the reliability and long-term stability of the product in the application.

2,Low thermal conductivity can effectively reduce the heat loss of the building to achieve energy saving and emission reduction.

3. Rock wool blanket will not release heat and poisonous smoke because of its incombustibility and can effectively partition the spread of flam when fire occurs.

4,It has good performance of non-hygroscopicity, ageing resistance and long-term stability.

5,It is light weight and easy to be cut and processed

Product Advantages:

1. Excellent thermal insulation

2. Fireproof

3. Good sound absorption property

4. Stable and durable.

5. High acidity coefficient

6. Good chemical stability and fiber durability.

Main Product Features:

Excellent performance

Fire-Proof

Good thermal Insulation

Soundproofing

Water-repellent

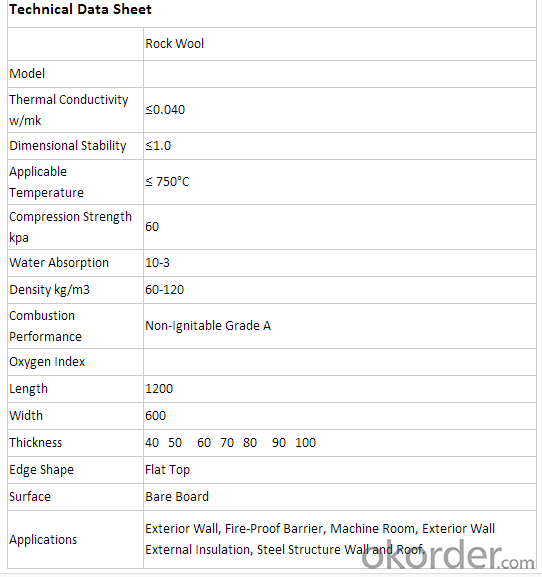

Product Specifications:

FAQ:

1.Q:What is your delivery time?

A : within 10-15 days after receive your prepayment,and we can also deliver as per your requirment.

2.Q:Which payment can you accept?

A: TT or LC.

3.Q:What is your MOQ?

A: 40'HQ container, that's about 65 cubic meters.

4.Q: I am interested in the products but I don't have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

5.Q: Can I get some samples for check?

A:Yes. Samples can be provided for free but you should take charge for the freight fee and we will deduct the cost from your first order.

Product Picture

- Q:What is the heat preservation material?

- According to the different material density, composition, range, shape and construction method of the insulation material, the classification is carried out:According to different bulk density is divided into: heavy 400~600kg/m3, light 150~350kg/m3 and ultra light, less than 150kg/m3 three categories.According to different ingredients: divided into organic and inorganic two categories.

- Q:What kinds of exterior wall thermal insulation materials are there in Northwest China?

- There are a lot of external insulation materials, including foam, mineral wool products, foam glass, expanded perlite insulation, powder particles insulation slurry EPS, spraying mineral cotton, foam cement insulation products, polystyrene particles, internal and external wall thermal insulation glazed hollow bead mortar and external wall putty and so on, you can according to the preferences and choose one or several price.

- Q:Rock wool, EIA inorganic insulation mortar, polystyrene particles, polystyrene foam board advantages and disadvantages comparison?

- Rock wool (mineral wool): it is a kind of inorganic green product from natural mineral, non-toxic and harmless. The utility model has the advantages of good fireproof performance and good durability, and can be synchronized with the structure life, and the price is low. When the insulation performance is satisfied, the utility model can also have a sound insulation effect, and the fire prevention grade is level a. But the quality of rock wool is very different, and the heat preservation performance is good, the density is low, the tensile strength is low, and the durability is poor, and the paint can not be used directly.

- Q:What are the requirements for floor and exterior wall waterproofing in building construction?

- The joining of different structural materials shall be made of salt resistant fiberglass mesh or hot galvanized galvanized wire mesh of not less than 150mm on each side for anti cracking strengthening treatment

- Q:Why should the insulation board be spliced when it is installed?

- The EPS plate shall be bonded in a vertical arrangement and the vertical seam shall be staggered along the line. Insulation board construction fault seam stitching truth with brick walls are brick seam is a reason for strong security.

- Q:What materials should be used for building energy saving? Why?

- Energy saving materials are widely used in building energy saving materials development and promotion in China. They have significant social, economic and environmental benefits, with great potential. At present, China's common energy-saving insulation materials are mainly rock wool, glass wool, polystyrene foam, cement, polystyrene board, silicate composite insulation mortar.

- Q:What are the properties of fire-resistant coatings for steel structures?

- Ultra thin structure fire retardant coating refers to the coating thickness of 3mm (including 3 mm) less than, decorative effect is good, high temperature can expand foaming, fire-resistant limit is generally less than 2 H steel structure fire retardant coating. This kind of fire retardant coatings for steel structures is generally solvent system, bonding strength, weathering has good water resistance, good leveling, good decorative features such as superior; subjected to fire slow expansion foam fire insulation layer to form a dense solid, the fireproof layer has a strong impact resistance, the temperature rise of steel delay, effective protection of steel member. Ultra thin intumescent steel structure fire retardant coating can be sprayed, brushed or rolled. It is generally used in building steel structures with a fire resistance requirement of less than 2 h. At present, there has been a fire resistance to meet or exceed the new ultra-thin fireproof coating for steel structure of 2 varieties of H, it is mainly based on the special structure of the poly methyl acrylate or epoxy resin and amino resin, chlorinated paraffin, compound as base adhesive, with high degree of polymerization of ammonium polyphosphate, melamine and pentaerythritol, double as the fire retardant system, adding titanium dioxide, wollastonite and other inorganic refractory material, using 200# as solvent and solvent oil compound. At present, all kinds of light steel structure, grid and so on, use this type of fire retardant coatings for fire protection. Because this type of ultra-thin fireproof paint coating, making use of thick and thin fire retardant coating for steel structure is greatly reduced, thereby reducing the total cost of the project, the steel structure has been effective fire protection, is currently promoting varieties on the market.

- Q:Which is better, roofing rock wool or glass wool?

- And glass wool is a kind of glass fiber, is a man-made inorganic fiber. Glass wool is the molten glass fibrosis, the formation of cotton like material, chemical composition of glass, is a kind of inorganic fibers. With good forming, small volume density, thermal conductivity, both thermal insulation, sound-absorbing performance, corrosion resistance, chemical stability.

- Q:What are the advantages of inorganic fiber spraying in construction engineering?

- Inorganic fiber spraying can be used for fireproof material, inorganic fiber spraying is widely used in the field of building insulation in 2003 China promulgated the "building materials industry standards of mineral wool insulation coating JC/T909-2003" specification of the inorganic fiber spraying construction and application of insulating layer. In recent years, building insulation layer caused by frequent fires, especially in the CCTV new site north side building fire is most well known, these frequent fires cause the domestic construction industry pay more attention to fire insulation materials, inorganic fiber spraying insulation material fire a advantage is to get attention.

- Q:Fire retardant plywood does not belong to non-metallic refractory building materials

- Materials are inorganic active insulation materials, foam, mineral wool products, foam glass, expanded perlite insulation, powder particles insulation slurry EPS, spraying mineral cotton, foam cement insulation products, vacuum insulation panel etc..

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rock Wool Thermal Insulation Board at Competitive Price.

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches