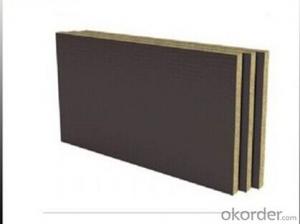

Rock Wool Sandwich Roof Panel Used in Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

The Rockwool Sandwich Panel production process adopts the colored steel plate as surface board and the core materials is the self-extinguishing closed cell rock wool, it is kind of high –strength composited building materials, and it was formed in the automated continuous molding machine, by combining the pressed colored steel with high strength adhesives.

Specifications:

Certification: ISO9001:2000 ISO14001:2004

Thickness Roof panel: 75,100,120,150,200 (mm)

Thickness Wall Panel: 50, 75,100,120,150,200 (mm)

Steel Thickness: 0.196mm~1.2mm

Density: 120kg\m3

Width: 960mm

Length: Arbitrary length according to the transportation, generally less than 12m

Color: Red, grey white, blue, green

Fireproof: A

Features:

Light weight: enough to reduce building expenses.

Time can be saved on a building project to the simple insulation.

Good durability: With special coating, the warranty of the color steel sheet is 5-10years. Lifespan of the panels can be up to 35years with spray-painting antirust on the steel sheet every 10 years.

The panels are fireproof and meet the relevant standards completely.

Good sound insulation for up to 40-50 decibels.

- Q:How can the exhaust pipe of a gas water heater be insulated by going through the glass?

- Therefore, the temperature of the inner pipe of the water heater is higher, but the outer pipe is not very high because the outdoor air is flowing.At the same time, the air is a poor heat conductor, so the actual temperature of the outer surface of the outer tube of the water heater is not very high. That is to say, no special heat insulation measures are needed when the exhaust pipe of the gas water heater passes through the glass.

- Q:What is the difference between high-density rock wool board and hard rock wool board?

- But the quality of rock wool is very different, and the heat preservation property is low, the tensile strength is low, and the durability is poor. Glass wool and rock wool in the performance of many similarities, but it feels better than rock wool, can improve the working conditions of workers. But it is higher in price than rock wool.

- Q:Does water paint spray fire in underground space?

- Waterborne paint itself is waterproof, unlike oil paint as security for.

- Q:What material is fast heated and kept warm?

- The gap between the heating tube and the aluminum tube is filled with a heat conductive insulating elastic rubber, so that the heat can be rapidly transferred to the aluminum tube.Conductive heat insulation elastic rubber adopts silicon rubber base material, boron nitride, alumina and other ceramic particles as filler, the heat conduction effect is very good. Under the same conditions, the thermal impedance is smaller than that of other thermal conductive materials. Having a soft, clean, no pollution, high insulation and radiation characteristics of glass fiber provides good mechanical properties to reinforcement, anti piercing, shear resistance, tear resistance, with conductive pressure-sensitive adhesive.

- Q:Why should the insulation board be spliced when it is installed?

- The EPS plate shall be bonded in a vertical arrangement and the vertical seam shall be staggered along the line. Insulation board construction fault seam stitching truth with brick walls are brick seam is a reason for strong security.

- Q:The classification of exterior wall insulation and its main categories

- The first is the product standard, the complete expansion of polystyrene board external insulation board system, this system in our country now use probably accounted for more than 62%, some statistics in 80%, because the statistics are not accurate, but it is the highest market share, is also the most mature external insulation system.

- Q:What materials should be used for building energy saving? Why?

- Energy saving materials are widely used in building energy saving materials development and promotion in China. They have significant social, economic and environmental benefits, with great potential. At present, China's common energy-saving insulation materials are mainly rock wool, glass wool, polystyrene foam, cement, polystyrene board, silicate composite insulation mortar.

- Q:Advantages of exterior wall energy saving and environmental protection heat insulation coating

- At present, there are many kinds of exterior wall insulation materials in the market, which can be divided into organic insulation materials and inorganic insulation materials. Materials are inorganic active insulation materials, foam, mineral wool products, foam glass, expanded perlite insulation, powder particles insulation slurry EPS, spraying mineral cotton, foam cement insulation products, vacuum insulation panel etc..

- Q:Fireproof rock wool board can be used as firewall?

- Composite rock wool board and slag wool board referred to as mineral wool, slag wool has been widely used in metallurgy, machinery, building materials, petroleum and chemical industry in 1970s, rock wool used for external wall thermal insulation in developed countries such as the EU has a history of nearly 30 years, but in our country because of its high cost and production cost, the economic costs of organic insulation the material is greater than, the application range is not big.

- Q:Fire retardant plywood does not belong to non-metallic refractory building materials

- Materials are inorganic active insulation materials, foam, mineral wool products, foam glass, expanded perlite insulation, powder particles insulation slurry EPS, spraying mineral cotton, foam cement insulation products, vacuum insulation panel etc..

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rock Wool Sandwich Roof Panel Used in Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords