Rock wool sandwich panels for prefabricated houses with best price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rock wool sandwich panels for prefabricated houses with best price

Rock Wool Sandwich Panel advantages

For more than ten years, sandwich panels with rock wool cores have been used successfully in a quick way of construction, having lots of advantages compared to conventional building systems:

Fast installation and convenient handling

Crane assembly and no scaffolding required

No thermal bridges and good thermal insulation properties

Plenty of design with choice of profiles and colours

Panels can be installed horizontally or vertically

Reliable robust mechanical performance

Outstanding non-combustible and acoustic performance

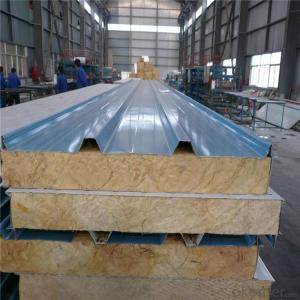

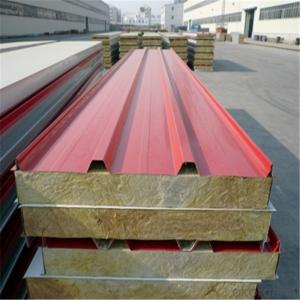

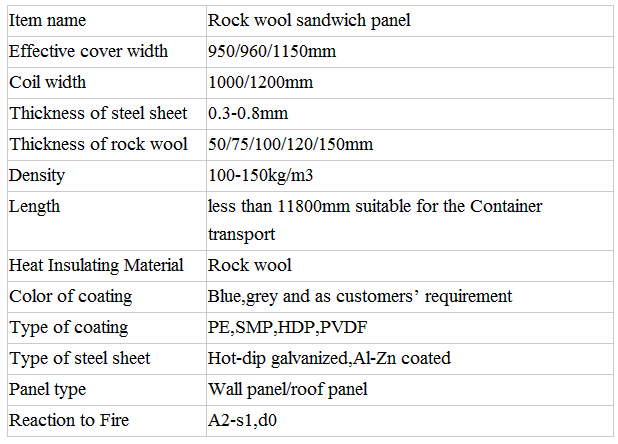

Specification of rock wool sandwich panels:

Applications

Rock Wool Sandwich panels cover all applications in steel building construction and prefabricated houses: external walls, roofs, partitions, ceiling panels, fire rated and acoustic sandwich panels for workshops,warehouse, industrial factory buildings, office buildings, stadiums, villas, and public buildings, etc.

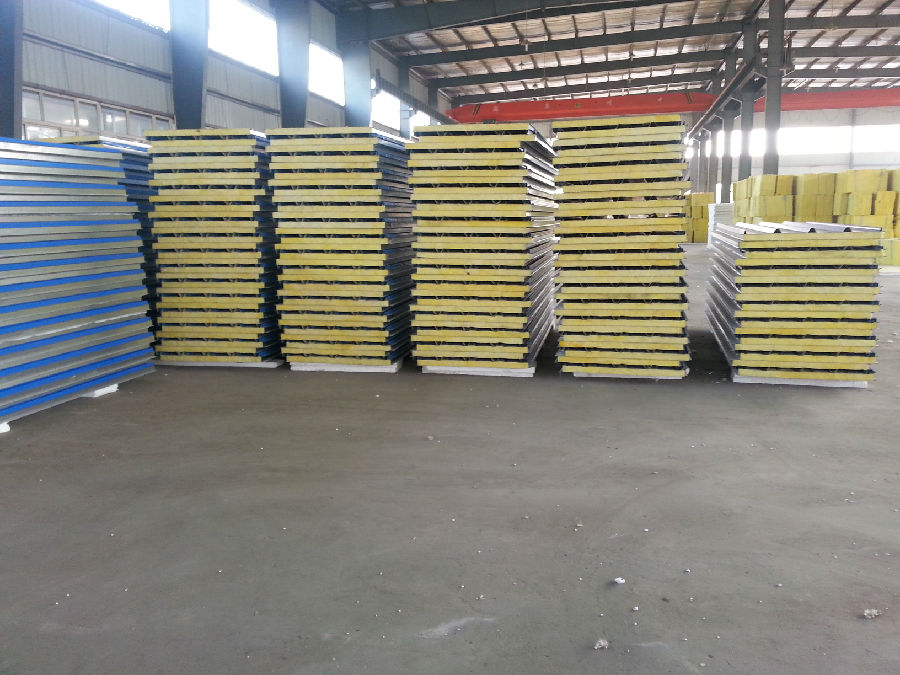

Workshop of rock wool panels

- Q:What is paper honeycomb sandwich panels

- Very simple two panels filled with honeycomb paper between the core layer!

- Q:What are the types of metal wool wool sandwich panels?

- Mainly Langfang BlueScope, OKorder Kangsai, Guangzhou Xisi Er, three companies are currently the best quality production of rock wool sandwich board company, its price is high level, other manufacturers of rock wool sandwich panels most of the Belong to medium or middle level

- Q:Have to know the holy spring Antwerp phenolic steel sandwich board how much money a square? I heard that the insulation effect is good, fire performance is also very good

- Phenolic insulation board a square 400 or so it Almost all of the price of phenolic need 50 points of oxygen was on fire, OKorder Zhongji machinery manufacturing phenolic insulation is the export, to the domestic sales a little less, you can order the next.

- Q:What is the latest export tax rebate rate for sandwich panels and color steel tiles? Thank you

- 3921199000 Other foam sheets, sheets, films, foils, strips Tax rebate rate 13% No regulatory conditions 7210700000 painted or coated iron or non-alloy steel wide sheet (width ≥ 600mm) Tax rebate rate 13% No regulatory conditions

- Q:I would like to ask, 50 thick metal sandwich panels per square meter generally have multiple ah?

- This depends on your use, generally do sandwich board bulk density in accordance with the 120kg / cubic meter to count, the weight of each square about 6kg, plus 2 side of the steel plate, up to 6.5kg or so! [Rockwell Rock wool / Structural rock wool composite panel

- Q:What is the difference between the board and the core board? Usually where the place with sandwich panels where the use of laminates, such as the use of the shoe is the board, wardrobe with a sandwich panel? So what is the difference between the two

- Daxing board is made of two pieces of veneer stagnant stitching wood. Daxin board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending pressure The strength is more ... but the general is best not to choose! 2. Plywood, also known as plywood, some people called the carefully board. Three or more layers by 1mm thick veneer sheet made of hot pressing. Plywood is generally divided into 3mm, 5mm , 9mm, 12mm, ... Plywood Optional plywood is made of multi-layer veneer staggered arrangement of the sheet. The outermost front panel is called the panel, the reverse is called the back plate. Core board.

- Q:Span 13 meters of the roof beam how to do the roof with 75mm foam sandwich board does not consider the wind load (indoor)

- Do you need to make a flat beam or a triangle? Made flat can use H-beam, do the triangle can be used C-shaped double-fight. Depends on your specific requirements.

- Q:Everybody is the polyurethane sandwich board to which manufacturers to buy?

- I came to tell you that I was buying polyurethane sandwich panels to go to Zhejiang Bo Ya building materials, where their products are not only durable, good quality, but also beautiful, there are a variety of styles, all kinds of places can be used on the

- Q:How many years can the life of the sandwich panel

- In general, ten years is not a problem

- Q:What are the varieties of foam sandwich panels? what is the price?

- Insulation and insulation The composite board commonly used insulation materials are: rock wool, glass fiber cotton, polystyrene, polyurethane, thermal conductivity is low, with good insulation effect. High strength with high strength steel as the substrate (tensile strength of 5600kg / cm) coupled with the most advanced design and roll forming, with excellent structural characteristics.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rock wool sandwich panels for prefabricated houses with best price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords