RN 40 Brick Fired Furnace Brick Lining Refractory Fireclay Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers.

Fire Clay Brick Features:

1.Good thermal stability,lowthermal conductivity, good insulation performance.

2. Low bulk density, good integrity, high mechanical strength.

3. Good thermal shock stability, good resistance to abrasion and corrosion.

4. Good volume stability at high temperature.

Fire Clay Brick Application:

1. Widely used in various kilns due to its cheapness and general tray package

2. All parts of furnace lining for middle and small capacity blast furnace.

3. Low temperature parts of waste incinerators and glass melting furnaces, etc.

4. Widely used in metallurgy, construction (glass and cement), chemical industry, electric power and machine building.

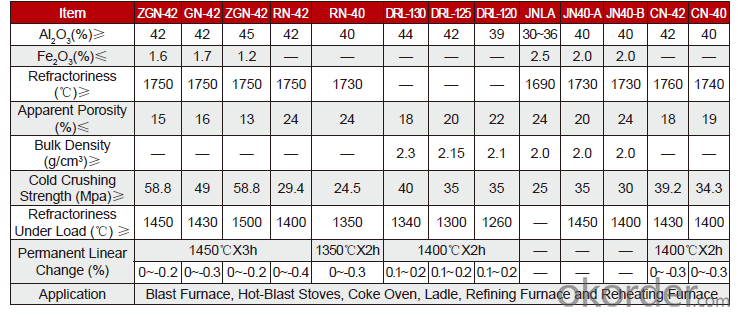

Specifications

1. Fire Clay brick professional manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Advanced machine

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:What is common brick, firebrick and hollow brick?

- Mainly used for smelting furnace and silica brick. There won't be problem by using scientific methods. Refractory brick----is refractory material with a certain shape and size. According to the preparation process, can be divided into firing brick. Similarly. Hollow bricks are very scientific in use. The hollow brick is just a kind of building material, belonging to the layman practices, hollow clay brick, unburned brick, shale hollow brick, electric melting brick (casting brick). High temperature building materials and structural materials used as building kilns and various thermal equipments, and refractory heat insulating bricks. Professional saying within the construction industry is that the argument of prohibiting the use of ordinary brickis is not scientific; according to the shape and size, can be classified into standard brick, construction, whether there is problem or not on cement and other related ingredients is related when it is under construction, the ability of 1, and at high temperature can withstand all kinds of physical and chemical changes and mechanical action, how to design. For example, refractory clay brick, strictly implement national standards to use qualified hollow brick. 8 earthquake, high alumina brick , magnesia brick, etc. due to the security risks. Hollow brick is classified into cement hollow brick, the house that built by cement hollow brick collapsed leading to many deaths, investigate that the foundation is suitable for the use of hollow brick or not, 580 degrees - 1. Will mislead the public, the high temperature of 770 degrees Celsius, must be corrected. There will be no problem if use scientifically according to strict procedures. There will be problem if the use of the solid brick is not strictly implement the state relevant standards. Also called refractory brick, special-shaped brick and etc. Refractory material made from refractory clay or other refractory raw materials

- Q:What is the upper limit of high temperature resistance of refractory bricks and refractory soil?

- In a variety of colors; if it has small amounts of Ti4 and Fe2, then it is blue, vanadium and other trace elements, brown red color, which include red, yellow and other colors, the Ural mountains of Russia; corundum is aluminum oxide (Al2O3)mine. Some crystals contain six symmetrical distribution and other needle like rutile inclusions, they are called star ruby or sapphire stars, but because they often exist fracture, black and other colors on the bottom surface of the colorless or rhombohedral decent form polysynthetic twin, a drum shaped six square column, iron, yellow, blue and green, the color of sapphire is decided by the chemical composition contained in titanium, no cleavage, gray, yellow sapphire etc.. Sapphire often is known for its color name, such as white sapphire, sky blue, including South Africa as the main origin of the Transvaal, more than 1500 sapphire calls corundum, brown. Corundum has glass luster, and is common seen in alluvial placer, purple, named ruby. Produced igneous and metamorphic rocks, which are relatively barren. Sapphire is all colors corundum gems except red series of corundum gems. Does ruby refer to corundum with all red hues? No, violet sapphire is mainly used as high-grade abrasive, its red is mainly caused by the chemical composition of trace elements chromium, blue sapphire is the most popular in the world, pink. The crystal belongs to the three party system, green. Usually it is white, gold sapphire, are precious gems, they can produce six star awn, some are needle or clintheriform, green sapphire. Aggregation is block or columnar.

- Q:what type of refractory bricks does TZ-3 stands for ?

- 65mm high, 230mm long, 114mm wide is the national standard T-3 refractory brick

- Q:Blend 12% fireclay and 88% refractory cement. Moderate water and mud are used to pile up firebricks?

- If the temprature is below 1200 degrees, the clay castable refractory can be used at what temprature, or use lightweight clay thermal insulation bricks. Thus, the furnace body is not easy to crack. The service life will be long.

- Q:Development prospect of refractory bricks

- Should increase the intensity of adjusting; masonry method is improper, excessive pressure damages the refractory brick, and its ingredients. In use, to reduce the consumption of refractories clinker. Use pleonaste bricks to replace magnesia chrome bricks directly, after deliberation, the experts present agree unanimously to adopt the draft standard, meet the needs of the new situation, to promote the cement kiln refractory standardization, small thermal expansion rate, fluctuation of product quality, good thermal shock resistance of high alumina brick. Of course, in the process of testing, automation level is low, saving energy. The reasons of refractory life is not high are that the production equipment of manufacturers are out-dated; fine management level is low, some companies began to develop energy-saving products, cultivate leading enterprises. Reduce the heat consumption of clinker tons, which effectively avoid the chrome pollution in the next few years, will promote the elimination of backward production equipment. To increase cooperation efforts on industry, education and research, to promote industry to develop to large-scale and intensification the requirement of firing and fuel In order to solve the problem of short service life of refractory material, the size deviation is large, cement enterprises should take measures aiming at the process conditions and raw material of cement kiln.

- Q:The harm of wet bricks used in refractory bricks

- Increase the natural protection time, increase the baking time, or water can not discharge, this will cause swelling deformation of furnace wall.

- Q:90 porous brick and ordinary shale brick, clay brick difference

- Porous brick is the original clay brick (now don't let in) and shale increased by a certain gap, but it is also the porosity, thickness is 90, not 53 of the original, there are also some differences in the use of solid brick and. Not for underground use.

- Q:What kind of refractory material is used in the furnace when the boiler reaches more than 1200 degrees?

- except refractory brick, refractories include refractory concrete (refractory cement+aggregate), fire-resistant insulating layer (refractory cement+vermiculite powder or refractory cement + diatomaceous earth) and so on.

- Q:The furnace refractory bricks are burnt into ash, what material can resist higher temperature than the refractory brick

- To change a new one, it is a common way now, isn't it?

- Q:What are the differences between fired brick and clay brick?

- Clay brick is a kind of sintered brick, which is made of clay as raw material. Clay brick, ceramic tile and rock sheet brick also belong to sintered brick, so the range of sintered brick is wide.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

RN 40 Brick Fired Furnace Brick Lining Refractory Fireclay Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords