Ringlock Standard Q235/345 Steel Galvanized

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ringlock Scaffolding

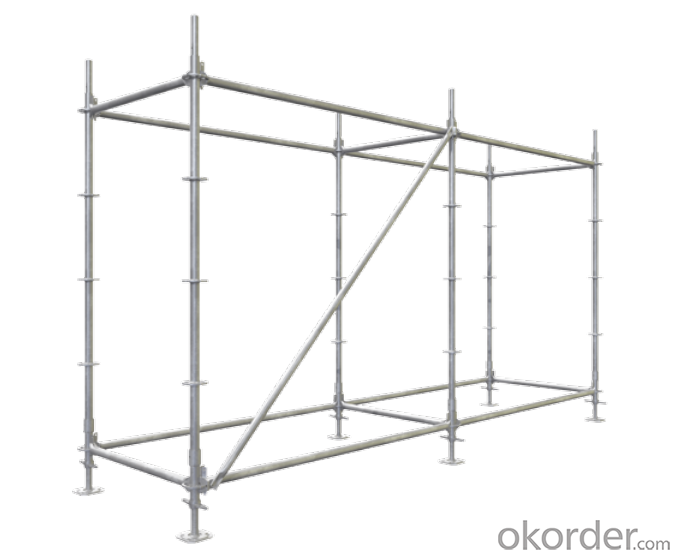

Ring Lock system is the latest item up to now. It’s mainly used in ship building, ship repairing, stage building etc.It’s stable, easy-assemble, easy working, safe-using and with big bearing capacity.

Main Features of the Ringlock Scaffolding

Place of Origin | Beijing, China (Mainland) |

Product Name: | Ringlock Scaffolding |

Custom Code | 7308400000 |

Color | Silver, golden |

Surface treatment | Painted,Hot-Dip,Galvanized,Electro Galvanized, Powder Coating |

Material | Q235,Q345.etc |

Package | Customized Package |

Payment Terms | T/T,L/C |

Delivery Detail | 15-25 Days |

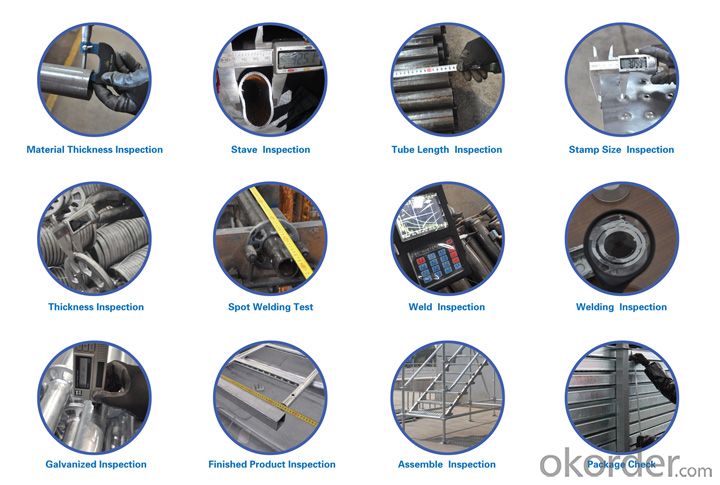

Quality Control | IS09001 Certification, Quality Test |

Standard | 48.3*3.25*4000mm |

Ledger | 48.3*3.25*3072mm |

Ledger End | 1.2kg |

Advantages

1)To be erected easily and quickly

2)Installed to different angels with rosettes of

two different hole being positioned there

3)Ringlock scaffolding provides complete flexibility to lock in any angel.

4)Diagonal braces are to be tailored in

accordance with the lengths of vertical and horizontal tubes

Product Show

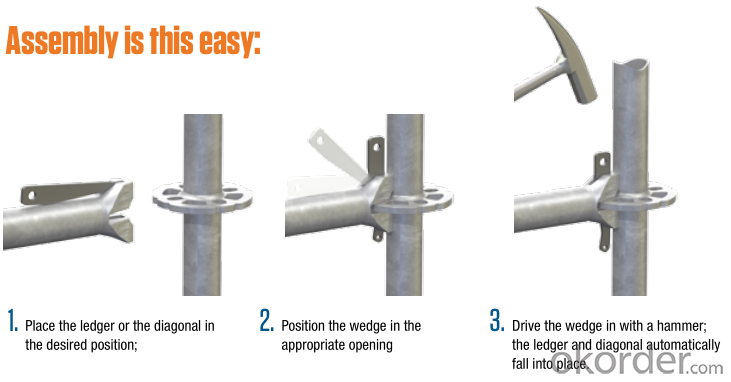

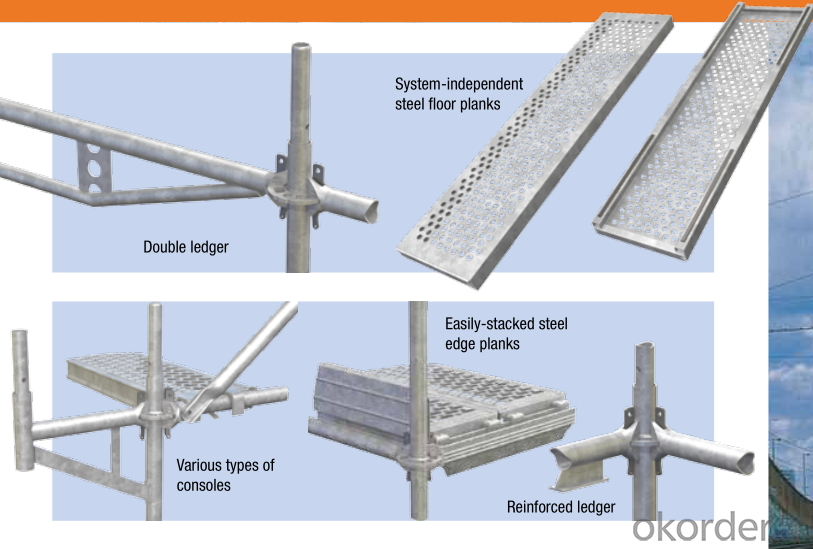

The modular RINGSCAFF system is characterised by the standardised, fast and simple assembly outlined above.

These procedures are continually repeated in the assembly of the scaffold.

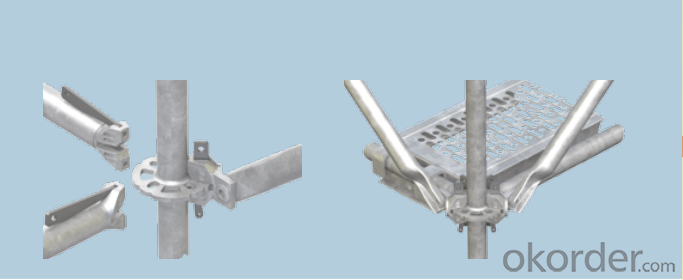

In this way, as many as four ledgers and four diagonals can be attached to one ring! This creates a connection point which can bear very heavy loads.

Specification of Ringlock Scaffolding

The Standards(Verticals) | ||||

Length(mm) | Tube Thickness(mm) | Tube Diameter(mm) | Surface Treatment | |

3000 | 3/3.25 | 48 | HDG/Painted | |

2500 | 3/3.25 | 48 | HDG/Painted | |

2000 | 3/3.25 | 48 | HDG/Painted | |

1500 | 3/3.25 | 48 | HDG/Painted | |

1000 | 3/3.25 | 48 | HDG/Painted | |

500 | 3/3.25 | 48 | HDG/Painted | |

The Ledgers(Horizontals) | ||||

Effective Length(mm) | Tube Thickness(mm) | Tube Diameter | Surface Treatment | |

2000 | 3/3.25 | 48 | HDG/Painted | |

1770 | 3/3.25 | 48 | HDG/Painted | |

1000 | 3/3.25 | 48 | HDG/Painted | |

The Diagonal Brace | ||||

Length(mm) | Tube Thickness(mm) | Tube Diameter(mm) | Surface Treatment | |

2411 | 3 | 48 | HDG/Painted | |

2244 | 3 | 48 | HDG/Painted | |

The bracket | ||||

Length(mm) | Tube Thickness(mm) | Tube Diameter(mm) | Surface Treatment | |

730 | 3 | 48 | HDG/Painted | |

Plank | ||||

Effective Length(mm) | Width(mm) | Height(mm) | Surface Treatme | |

2050 | 480 | 45 | HDG | |

1820 | 480 | 45 | HDG | |

3000 | 240 | 45 | HDG | |

2000 | 240 | 45 | HDG | |

1000 | 240 | 45 | HDG | |

Hollow Head Jack And Jack Base | ||||

Length(mm) | Tube Diameter(mm) | Size of Plate(mm) | Surface Treatment | |

600 | 38 | 150*120*50*4 | HDG | |

600 | 38 | 150*150*4 | HDG | |

- Q:Is there any reason why you shouldn't?

- I think that depends on the application and how you want your floor to look. They tend to be about 2 thick and wide (which is good for a scaffold). But most flooring is only 3/4 thick. If you have a way to resaw them that might be good. When I was a kid (1965) I worked in a factory with a wood floor and the boards were 2 thick and about 8 wide. This was a good floor when the factory was built about 1920. Not so good these days. In the right setting they could be very interesting and decorative especially if you can leave the old paint and marks on them.

- Q:I Got It On The 16th Of Feb This Year, I'm 14 Year's Old, So Don't Laugh, Okay I Can't Unscrew The Ball Things And How Long Does It Take To Heal Fully? __Ciara-Chemical__

- Thats an awesome piercing, nice job! I'm not laughing about being unable to unscrew it - I have a piercing in my pinna I've never been able to get out - had it for like 6 months. What I will say it that you shouldn't be taking it out yet really anyway. If you wash it in sea-salt and warm water once a day it should be almost totally healed in 8 weeks, which is still about two weeks away if you got it on the 16th Feb. Even then for the first 6 months or so it'll close pretty quickly (not in like an hour or anything, but it could get tighter in as little as 3 or 4 hours), so you should try to leave it in all the time for that 6 month period.

- Q:Door type steel pipe scaffold, bowl type, plate type, what is the disc pin?

- Among them, the proportion of steel pipe fastener scaffold is larger, and the door type scaffold is mainly used for decoration and indoor construction

- Q:I'm asking this in favour of my friend who currently has no internet.She had her scaffold piercing done about 2 days ago and today it got knocked and started bleeding. It's been bleeding for about 3 hours now and she's worried about it.

- First you gotta stop touching it, that's probably causing the irratation, hence bleeding. IT'll take time to heal, just leave it alone clean out the blood every hour or so, BE CAREFUL! and LEAVE IT IN!

- Q:at what age can you get a scaffold/industrial piercing in england without parental consent?

- there actually are no laws in the UK about piercings other than the genitals and female nipples (you have to be 16 to get pierced in any of those locations) it is up to individual studios on what age they don't require parental consent. the best thing to do would be to contact your local shop.

- Q:What are the specifications of the bowl fastener? What kind of?

- More commonly used specifications, there are other types of special-shaped. Unit cm cm.

- Q:In the process of high-rise building construction, bowl buckle type steel pipe scaffolding foundation and foundation treatment should meet the requirements

- The foundation and foundation treatment of bowl buckle scaffold should meet the requirements of standard JGJ166.

- Q:And how long do you have to keep it on? Any other knowledge I should know?

- 8 - 16 weeks - healing time. But with some people it can be alot longer! Clean 3 - 4 times a day. Try cleaning with a mix of tea tree oil and water! It doesn't hurt much :)

- Q:Thinking about getting this peircing done next. I got my first and second peircing on my lobes and neither hurt at all to me (like .5 out of 10). How much does industrial hurt out of 10? Is it a similar pain to lobe peircing? Also how long does it take to heal, until you can take it out and sleep on it?

- For me, I'd rate it's pain level at about a 5. Just all depends on how well you tolerate. It's more uncomfortable than getting a lobe piercing, really not that similar. Mine took about about 6-8 months to heal for changing the jewelry, but took like maybe 2-3 months until I was able to sleep on it again. Good luck if you get it.

- Q:Scaffolding with children that is.

- It is expected that students will: ? identify elements of their own cultural backgrounds ? identify elements of Francophone culture in Canada You can find the Provincial Prescribed Learning Outcome document here. So, instead of having teacher-directed lessons discussing the elements of the Francophone culture in Canada and comparing it to our own cultural backgrounds, I handed the PLO’s to the students and let gave them ownership over how they wanted to explore these topics and how they wanted to demonstrate their learning. Even though we had opportunities to do Genius Hour throughout the year, it was still pretty foreign to them to have complete ownership over their own learning. They choose to work on their own or with a partner or in small groups.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ringlock Standard Q235/345 Steel Galvanized

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords