Ringlock Scaffold with SGS SGS AS/NZS1576.3 Certified for Supply CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Ringlock Scaffold with SGS SGS AS/NZS1576.3 Certified for Supply

Type:Fixed

Material:

Construction Properties:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Materials Standard:

Materials Specification:

Qualified Certificate:

Surface Treatment:

Standard Size:

Ledger Size:

Descriptions of Ringlock Scaffold with SGS SGS AS/NZS1576.3 Certified for Supply

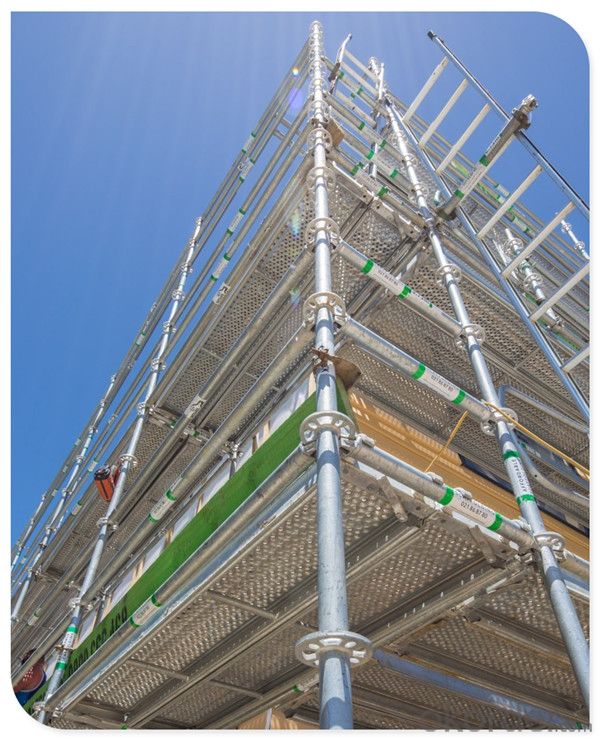

Ringlock is a modular scaffold system which can provide major savings in labor costs while meeting the demands for safety, ease of handling and reductions in maintenance.

Ringlock scaffold has the following features:

Quick erection: Ringlock scaffold are all pre-measured and just a hammer is required when erection.

Versatility: The revolutionary node point- rosette provides up to 8 connections in one plane, allowing the system scaffold highly adaptable for straight as well as curved structures, such as ship yards, power generation stations, petrochemical plants.

Low maintenance: The dip galvanized finish will greatly last the life of the products, no paint required, no more rust or corrosion, even they can be stored externally.

Safety: The reliable wedge connections prevent ledgers and diagonal braces from any kind of loosening, The rigid, right fit of all connections with concentric derivation of loads guarantees safety even at great heights. Reasonable customer requirement is acceptable

The System of Ringlock Scaffold with SGS SGS AS/NZS1576.3 Certified for Supply

Ringlock

Scaffold

SystemStandard

Q345 tube

48.3*3.25Procedure Size Weight(kg) Surface Certificate

1.Cutting

2.Drilling

3.Plating cutting

4.Forming

5.Welding

6.Remove welding slag

7.Galvnize

8.Surface finish

9.Assembling

10.Packing

11.Logistics0.5m 2.96 HDG SGS ISO EN 1.0m 5.33 HDG SGS ISO EN 1.5m 7.73 HDG SGS ISO EN 2.0m 10.06 HDG SGS ISO EN 2.5m 12.42 HDG SGS ISO EN 3.0m 14.78 HDG SGS ISO EN Ledger

Q235 tube

48.3*3.250.73m 3.81 HDG SGS ISO EN 1.09m 4.93 HDG SGS ISO EN 1.40m 6.44 HDG SGS ISO EN 2.07m 8.71 HDG SGS ISO EN 2.57m 10.64 HDG SGS ISO EN 3.07m 12.41 HDG SGS ISO EN Brace

Q235 tube

48.3*2.51.5*2m 9.04 HDG SGS ISO EN 2.0*2m 10.05 HDG SGS ISO EN 2.5*2m 11.42 HDG SGS ISO EN 3.0*2m 12.13 HDG SGS ISO EN Bracket

Q345 tube

48.3*3.20.35m 4.5 HDG SGS ISO EN 0.75m 6.7 HDG SGS ISO EN 1.1m 9.9 HDG SGS ISO EN Plank

Q235

1.5mm

1.8mm0.73m 5.1 HDG SGS ISO EN 1.09m 6.9 HDG SGS ISO EN 1.4m 8.85 HDG SGS ISO EN 2.07m 12.11 HDG SGS ISO EN 2.57m 15.02 HDG SGS ISO EN 3.07m 17.69 HDG SGS ISO EN base

collar0.16m 1.7 HDG SGS ISO EN 0.2m 2.1 HDG SGS ISO EN Toe

board

wood

15*1.5cm0.73m 2.16 anti-fire ISO EN 1.09m 2.98 anti-fire ISO EN 1.57m 4.12 anti-fire ISO EN 2.07m 5.75 anti-fire ISO EN 2.57m 6.88 anti-fire ISO EN 3.07m 7.98 anti-fire ISO EN

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:I know its between chapters one and two, duh. Haha, but yeah, I needa do this thing on Edmodo for school, but i accidentally left my book in my locker.):I tried looking at online versions, but you know it's so hard, right? Looking and seeing all these different versions and I cant find the place...I need where she entered the scaffold because I need to cite where she thinks about how she's accepted her quot;sinquot;. So yeah~ PLEASE HELP! ( gt; . lt; )

- i'm no longer completely constructive of the answer to this actual question, yet I only finished a unit in this novel and could like to help with any extra questions...be satisfied to invite -Alice

- Q:i just need to know the age limit with parental permission?

- I'm pretty sure it's 16-17 with parental permission. I suggest looking up some of the shops in your area and seeing what they say. There usually isn't a set rule for it, every shop is different. Like some shops may refuse seeing, say, a 14 year old, whereas another shop might do it with the parent's permission. Then of course, once you hit 18, you can do whatever you want, lol.

- Q:Does anyone know the name of the song or perhaps have a link to the video if they have seen it on net for example on youtube.?

- I think its 'Aint goin down til the sun comes up' but I'm not 100%, sorry.

- Q:what are two burdens for each character? What action does each character indicate that she or he is indeed free from their burdens?

- Tell me what you know and I will elaborate. I had to read this book for a class and hated it, but I won't do your homework for you. I will help if you show you read it yourself and put in some effort we can see

- Q:What are the requirements for acceptance of external scaffolding? Want to know before

- Hello, this has the following specifications: safety 1, set up a high level scaffolding, the various materials used must meet the quality requirements. 2, the foundation must be firm, before the erection of the calculation, to meet the load requirements, and according to the construction code set up, do drainage measures. 3, scaffolding erection technical requirements shall comply with the relevant provisions of the code

- Q:I sincerely ask you to help me, door scaffolding, build 30 meters high, without any reinforcement points of the construction program. Thanks, high marks!

- The height of the erection of the steel pipe scaffold shall not exceed the provisions of this specification 1.0.3.The design and construction of the 1.0.4 door type steel pipe scaffold shall comply with the relevant provisions of the state and the relevant mandatory standards.

- Q:What are the general specifications of bowl buckle scaffold?

- 2, of course, scaffolding to the new is better than the quality of steel is much improved with the old, regular use can generally be used for about 10 years, abandoning the bolt connection. Component jingpengnaike. Even if the corrosion does not affect the spelling and use. This does not require special maintenance and maintenance. Fastener type steel pipe scaffolding in general about 3 years on the need for screws and other operations. So I think it is convenient to bowl buckle scaffold. 3, disassembly more secure, more convenient, better performance than traditional fastener type steel pipe scaffolding.

- Q:hi, i already have my cartlidge pierced on my right ear and thinking about getting a scaffold piercing on my left ear. will a scaffold piercing hurt more than my cartlidge piercing,,less,,or about the same???thanks answers apprecietedhope =] xx

- Several people have told me it hurts about the same. I do not have one, sorry couldn't be more help than that.

- Q:what is the height of a scaffold if the person is 6ft tall?

- Whatever they set it at. It could be 1 foot, 4 feet, or 20 feet. How tall a person is, is irrelevant.

- Q:Im thinking of getting a scaffold piercing when i am old enough to and ive seen videos of people who have one but it cause bacteria in their ear and if they take it out their ears swell. I want to know if this is a bad piercing to get. Also i have had an allergic reaction to an earring before and im not sure what type of earring it was. Can that affect it as well.

- It shouldn't be dangerous if you go to a good piercer (mine pierced mine funny) and clean it regularly. and it should be fine, Just learn which type of earring you;re allergic to and make sure they dont pierce it with that kind of metal.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ringlock Scaffold with SGS SGS AS/NZS1576.3 Certified for Supply CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords