Rhombic Form Traveller

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

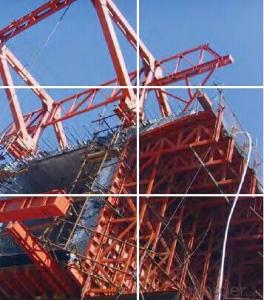

RHOMBIC FORM TRAVELLER

The rhombic form traveller has the advantages of simple structure, clear

stress, big operational space under the main frame, and easy installation

and removal, etc..

The form traveller adopts wheels with bearing while rolling forward which

reduce the frictional resistance greatly during movement; At the same

time, the stainless steel paltes are welded on the rails which reduced

the frictional resistance bewwen the sliding bearing and the rails during

movement. The combination of these reduce the movement cycle of the

form traveler by simple and convinient operation.

In terms of safety, the form traveler is equiped with walking protection

system which guarantee the absolute safety during working. It’s safe, easy

and practical.

● Low gravity of front trancerse beam

● Applicable to large-scale stay-cable cantilever casting bridge with wide bridge deck

● Safe & easy operation, easy fixing, and safty during walking

● Big operational space under the main frame, and easy installation and removal

- Q:Can the vertical prestress of the hanging basket be tensioned after the subsequent section construction?

- Yes, but it should be decided according to the drawings.

- Q:Can you please list them ALL because I really need it for my book report =) thanks

- Some will eventually answer this for you but you should consider doing your OWN homework. This is actually a really nice story so you should read it!

- Q:Characteristics of the hanging basket

- Main features of hanging basket construction1 can bear the weight of the beam section and construction load:2 stiffness, small deformation;3 lightweight structure, easy to move forward;4 the scope of adaptation is large, and the bottom mould frame is easy to lift, which is suitable for different beam height.

- Q:Is hanging basket equipment special equipment? Need to record it?

- Special equipment regulations on safety supervision of special equipment is the safety of life, the risk of large boilers, air compressor and the air storage tank, tunnel construction hoisting machinery (construction elevator, tyre crane, crawler crane, gantry crane, tower crane, bridge machine), hanging basket construction equipment etc..

- Q:I would like to know that each piece of the construction of the hanging basket is connected by way of the whole as a whole, I always think of each section is a section of tension.As you said, the steel strand is the length of the whole beam, but how to form the whole concrete?

- Pour the mud into the joint! Elephant building interface!!! Have to reinforce!! Reinforcing bar! That's it.

- Q:What is the meaning of "hanging basket" in building construction

- Through the wire rope and special tools for lifting, standing on the platform to operate.

- Q:Car hanging basket, green, yellow different license, according to what standard hang

- Test license: yellow black, after the word "trial" words; foreign vehicles temporary entry license: white red black and white words "temporary entry";So that a small number of foreign car license on the consulate of the country is the name of the establishment of diplomatic relations, and the number of regulatory authorities in the region has nothing to doAs well as the emergence of the first period of Beijing personality license. White blue at the end of the six character numbers or letters, black fontThere are also a wide variety of game licenses

- Q:Cantilever pouring construction should pay attention to what

- The main equipment of the cantilever method is a pair of walking hanging basket, pull anchor in Zhang and pier has connected mobile beam on the whole hanging basket, lashing reinforcement, formwork, pouring concrete, prestress are carried out on the. After the completion of the construction of this section, the hanging basket symmetrical move forward a section, the next pair of beam section construction, in advance, until the cantilever beam section pouring completed.

- Q:Is there any paperwork and forms a traveler from USA to Dubai should look into?

- You do not need any paperwork if you travel to Dubai. USA citizens do not need visa for Dubai. You can just go trough the immigration and they will give you a visitor visa for 30 days.

- Q:Hanging basket construction continuous beam, the adjacent fast is how to connect, such as Block 0 and block No. 1

- 4, pouring the whole section of the next section, until the strength of more than 80% after the design, before and after the left and right sides of the steel cable.5, in the long hole bellows (such as 1# to 0# to 1 "# long hole grouting filling) within reach the design strength, namely two adjacent segments after connection.6, 2# segment connection (2 ', 1 #' #, 0# block, 1#, 2# in steel wire connection).7, 3# segment connection (3 ', 2', 1 # # '#, 0# block, 1#, 2#, 3# in steel wire connection). The remaining segments are, in turn, connected like strings of pearls.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rhombic Form Traveller

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords