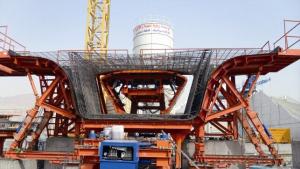

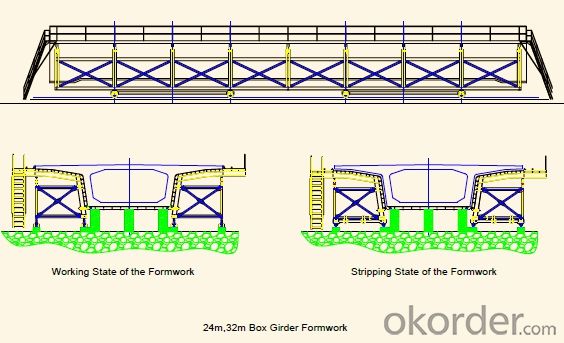

Revolving Dismantled Box Girder Formwork

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

BOX GIRDER

External formwork of 32/24 meters post-tensioning concrete pre-faricated box girder is divided into sliding mode and

rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the

utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode

is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency

of formwork closure.The side formwork unit is mainly 6 meters, the design of the sructure is compact

and reasonable with beautiful and smooth appearance.

Features

■ All the edges of ecternal formwork panels for the box girder have been milled, which ensure

the assembly precision to avoid the leakage of the concrete

■ The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment

■ The bulkhead is designed to envelop the sideform,which can be wholely assembled, making the removal, installation and adjustment much easier.

- Q:How to control the elevation of the beam bottom and the axis position

- The axis is controlled by hanging the ball down to the lower floor axis and the axis control line.

- Q:When Liang Banzhong beam template calculation is the calculation of him in the board? Because in the calculation of engineering quantity of concrete beam by beam plate calculation. But when the template is, the book is not clear. In the calculation of the time quota template can have a beam plate.I use the Guizhou 04 quotaEspecially your last sentence, I haven't said anything yet,There is the Guizhou 04 fixed and did not say what sub beam frame beam separationAbove the beam plate is to explain the main beam, sub beam and plate, according to the calculation of beam and plate volumeThen you explain to me the frame beam is not the main beam? According to this explanation, why do you separate the frame beam

- Calculate the area between the axis, into the wall of the plate into the area of the plate, and then deduct more than 0.3 of the hole, that is, the area of the beam plate

- Q:The bottom of the board 12.24*7.44 why not *2 floor 12.24 of the two of the 7.44 also have the plate side mode *2 is * of the two or both

- The beam of the template is to calculate the beam height (minus the plate thickness of the part) * net long *2 surface. The bottom die has been calculated in the bottom plate.Louzhu certainly not familiar with the construction site, as long as the scene to see how the template is placed.

- Q:I would like to ask the template support system Liang Xiaoliang Ban Xiaoliang refers to what

- High formwork concrete beams are usually large in size, gravity load, plan people sometimes use 50 x 100 (width * height) wood brace, called Liang Xiaoliang, a thin concrete slab gravity load is less, with 30 * 80 mu Fang, challenge the small beam. According to the different rib beam floor plan, good people, they try to use the same specifications of the wooden architrave, there is no Liang Xiaoliang, small plate beam, just calculate book Liang Xiaoliang, trabecular plate.

- Q:Known length of 50.8 meters, known to be designed for the width of the area of the loss of 1 x 0.25, I have calculated the base cap,. {1.0 * 0.25 + [0.37 + 1 x 0.1 / 2 + 0.47 * 0.1] on the bottom and bottom formula is multiplied by the divided by two. So how to calculate the foundation beam. Formwork and cushion,

- The calculation of the net area on both sides of the formwork. Cushion volume should be very good

- Q:Which part of the middle beam and side beam in the T beam template? Thank you

- The use of T beam highway bridge generally 5 pieces of beam for the span of 1, which is the outermost of the two to become [edge beam]

- Q:Remove the larger span of the beam pillar template why should be removed from the middle to the two ends

- When the formwork of the beam is not removed, the load of the beam is evenly distributed. If the two ends of the span from the demolition of the words, the load is borne by the beam at both ends of the column and the template in the cross, when the removal of the template in the cross, the beam is likely to produce cracks and damage. Only from the cross to the ends of the removal, the load is evenly distributed to the ends of the column, the beam will not be destroyed.

- Q:How to put the beam formwork in concrete structure

- By way of hanging on the board, you do not want to put a line for you!

- Q:When the height of the beam is small, the beam of the beam is tied up on the top of the beam formwork; when the beam height is large, the steel bar of the beam is bound on the bottom of the beam. What do you mean?

- When the beam height is large, the beam of the steel beam in the bottom of the bundle, which means that the beam of the overall weight of steel, in the Liang Dimo binding, and then seal the side template, and then pouring concrete

- Q:For example, a beam 200*400, length 5000Plate thickness 1005000*5000The area of the template is1, (0.2+0.3*2) *5+5*52, 0.3*2*5+5*5Which is right

- The beam of the template is to calculate the beam height (minus the plate thickness of the part) * net long *2 surface. The bottom die has been calculated in the bottom plate.Louzhu certainly not familiar with the construction site, as long as the scene to see how the template is placed.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Revolving Dismantled Box Girder Formwork

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords