Resin tile fire-resistant high-quality environmentally friendly

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Advantage

1. Persistent color

2. Excellent load resistance

3. Sound: Experimental proof

4. Impact resistance, good low temperature resistance

5. Excellent corrosion resistance

6. Excellent thermal insulation properties

7. Excellent self-cleaning performance

8. Stability

9. Excellent waterproof performance

10. Excellent electrical insulation properties

11. Fire resistance

12. Installation is quick

13. Green

Product Usage:

Wave board is a new type of fashion art interior decoration sheet. Decorative materials are mainly used in hotels, clubs, home decorations, dance halls, resorts, shopping malls, mansions, villas and other renovation works, especially for entry, entrance, backdrop, TV wall, column design, bar, exhibition. Can replace the natural veneer, Tiemian Ban, and so on. There are dozens of patterns, such as pure white board, paste gold, silver, pearl plate, star board, crack lacquer plate, lacquer plate, which makes corrugated cardboard, corrugated board, stone and nearly 30 kinds of effects.

Product Description:

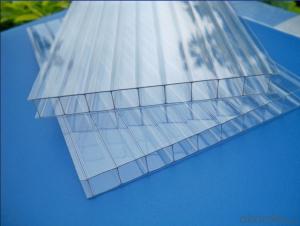

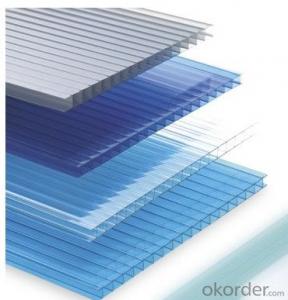

Environmentally friendly synthetic resin tiles are hard PVC plastics and modified ASA resins High weatherability Substrate surface materials are extruded through two extruders, PVC compounded and resin modified ASA materials such as plastic, Or circular wave type water dispenser head into the compound made of double composite plate, and then by a special continuous stereotypes stereotypes, cutting processes, the final color of the green resin for the formation of green ceramic tile products.

- Q:To build a sunshine shed, with Cortron PC patience board or good sun board?

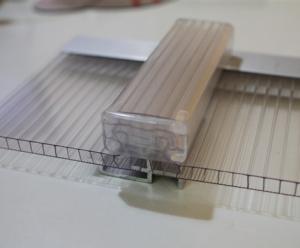

- Nai Liban board a little better, but the cost of the durability plate is too high, the sun will have a lot of concessions, the general use of four sun panels, structural stability, high quality performance. Pc sun panels for the production of polycarbonate as the main raw material. At present the international widely adopted a high-intensity, translucent, sound insulation, energy-saving new high-quality decorative materials. Sunshine plate in the mid-80s into the building materials, decorative materials market. Than the laminated glass, folder glass, tempered glass, insulating glass more light, weather, super, flame retardant, sound insulation of the excellent performance, due to the special quality of the sun plate. Get the architectural design, decoration works, environmental engineering, advertising industry generally recognized.

- Q:PC sun board life years?

- 10 years warranty is 10 years, light transmission rate decreased by 6%, yellow index change is less than 6. This is the plastic is not too much of the aging indicators. Means that after 10 years of good sunshine board physical mechanical properties decline is very little, basically will not affect the use of sex. Foreign pc sun panels are basically used for more than 20 years. Good pc sunshine board is not like the above answer "is to provide", rely on equipment, technology, raw materials, testing means. Generally speaking, imported equipment uv co-extruded layer thickness is more uniform, the service life will be longer.

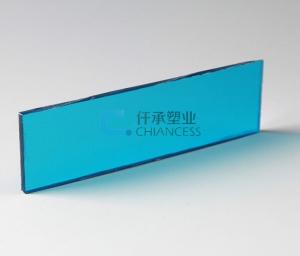

- Q:Sunny plate that is a transparent that I want to use the home screen 4mm thickness can be about how much a square

- Screen, then you can use matte endurance board or particle stamina board, more beautiful. 4mm thickness is enough. Can be strong The quality of the general should be much cheaper. Home with the proposal to buy that, ten years warranty. Recommended goods-PC patience board, the domestic material this one more famous.

- Q:What is the difference between sun panels and plexiglass?

- Sun panels are generally hollow, plexiglass is solid. There is one side of the sun is anti-condensation, one side is anti-ultraviolet. Plexiglass on both sides. Sun panels can be exposed directly to the outside, and plexiglass generally can not accept direct sunlight.

- Q:Project sun board price how much

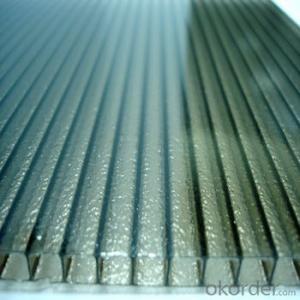

- PC sunshine board price is calculated per square meter as follows: Thickness of 6mm - 16mm, the general price of 25 yuan -100 yuan / ㎡, the thickness of the sunshine plate is more commonly used, the structure is divided into two layers, three, four, X type, meter type, honeycomb type.

- Q:What are the differences between plastic endurance boards and sun panels?

- Color: transparent, blue, green, creamy, brown, gray.

- Q:PE sun panels and PC sun panels are different

- Different materials, PC is environmentally friendly, PC temperature, PE is not temperature

- Q:Can sunscreen be insulated at night? PC sunshine board insulation performance how?

- PC sun panels are lower than ordinary glass and other plastic thermal conductivity (K value), insulation effect than the same glass 7% -25%, PC sunshine board insulation up to 49%. So that greatly reduce the heat loss, for heating equipment, building, is environmentally friendly materials.

- Q:What is the difference between sun panels and lighting panels?

- Matching FRP lighting panels can be customized with the roof color plate exactly match the cross-section, and low cost, convenient and fast. PC board is based on the main plate, the specifications of more thickness, can be a good choice for their own sun panels, easy installation, fast.

- Q:PC sunshine board, what material, what kind of good

- Hello, the thickness of the sun board is generally 10mm, 8mm, 6mm and other specifications, in the color also has a lake blue, transparent, white and other colors, available to users according to their actual needs and preferences to choose.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Resin tile fire-resistant high-quality environmentally friendly

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords