Resin P500

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20Ton m.t.

- Supply Capability:

- 5000 Ton/Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Property of Resin P500

• Resin P500 is a promoted and thixotropic toughness unsaturated polyester resins, which has perfect mechanical properties and higher elongation.

Applification of Resin P500

• FRP products such as tanks and pipelines.

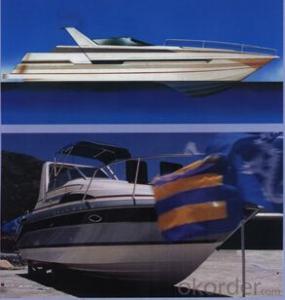

• FRP boats, such as fishing boat, marine/yacht, life boat, etc.

• Used in fabricating pultrusion molding tent pole, fishing rod, insulating rod, etc

• Can be used in filament winding, pultrusion, hand layup and spray-up process.

Spercification of Resin P500

|

Property |

Specification |

|

Epoxy Equivalent Weight (g/eq.) |

184-194 |

|

Viscosity (mPa.s @ 25°C ) |

11000-15000 |

|

Hydrolytic Chloride (mg/kg) |

≤300 |

|

Water Content (ppm) |

≤700 |

|

ECH Content (ppm) |

≤5 |

|

Color, APHA |

≤30 |

|

Volatile ( % ) |

≤0.1 |

|

Appearance |

Pale yellow oily liquid without obvious impurity |

|

Packaging: Epoxy Resins are packed in iron drum of 220±1kg or 20±0.1kg. | |

|

Storage: Should be stored at a ventilative, dry and clean place and far from fire and heating devices. | |

|

Transporting: Should be far from raining, direct sunlight, humidity and heating sources | |

Packing & Storage of Resin P500

• The product should be packed into clean, dry, safe and sealed container, net weight 220 Kg.

• Shelf life: four months below 25℃, stored in cool and well ventilated place.

- Q:I was fired 6-22-10 for telling my mang. I ate 1 piece of candy in claims, he told me it was ok and then pulled me in 2 weeks later and told me to write down what I said then he turned around and fired me.now I know they are getting rid of Dept. mangers I have been there 12.5 years never been wrote up never in trouble. I have to tell you I was head butted 2yrs ago by another employee I broke my wrist and they never even wrote up this emploee he never got into trouble for this .I didn't due any thing because I didn't want to loose my job I was told if I sued I could loose it well everyone told me I would be let go in a couple of yrs because of this accident now I'am wondering about it!! also there has been other people in that store that has ate candy and didn't get in trouble including the guy who head butted me. I'am 54 yrs old and this has messed my head up alot I'm still upset over this. I was always for walmart now I hate that place sooo much. what do you think?

- You can just put it in the oven, it will not damage the pan or the oven. However, for ease of taking it in and out, I usually put my silicon pans on a cookie sheet. Becasue silicon pans are sort of floppy I find that it makes it a lot easier to move them, and makes the bottoms of my cakes and stuff more flat.

- Q:What's the matter of producing resin crafts with holes in them?

- There are two ways to solve this problem:1, resin vacuum2, perfusion in a vacuum

- Q:My smoke detector in my hallway has been going off for NO reason. No smoke, no nothing. I'm sure its a smoke detector and not a carbon monoxide detector. Three weeks ago it started to go off, and then it stopped. Today it went off with a single beep. A few minutes later, it emitted three beeps, then one. It just goes off at random times and is annoying the crap out of me. Can anyone tell me the problem?

- you do no longer seek for the answer to this question, for you recognize the respond, all too nicely. ~~~~~ each little thing that glitters isn't gold and each little thing that's risk-free to eat isn't nutrition. ~~~~~ One could think of important strategies which comprise those! The 'human senses' are generally deceiving, is it no longer so? Peace be consistently with you. in sha'Allah al-hamdu lillah Salaams,

- Q:So anyway I made a resin charm.. And it contains Easy Cast Resin With Glitter.. I have made other resins before. But anyway.. So theres this charm that won't dry! Its been sitting there in the mold for more then 2 months! Its a little sticky.. When i touch it. So what should i do to fix it? Like make it dry and complete? Could i just take it out? So what should I do to fix it. And Could i take it out without ruining the mold? The mold is made out of Plastic btw.

- They make flexible molds for resin, use those, but the mold putty ones are great. I use those and they are easy to get the resin out. For color there is dye for resin, and you can add anything you want into the resin, glitter, sprinklesetc. For adding a photo yes you need to apply mod podge on the image so that it does bleed or run into the resin. I hope that helps you! Oh and make sure to do the resin outside, it is very toxic.

- Q:Who said &If your neighbors house was on fire, wouldn't you give them a hose?& HELP!!!!?

- . HTH, Diane B. P.S. You can also use some of the 2-part epoxy *glues* instead of the larger containers of epoxy resin if you're doing only small items. One very clear one (at least in the US) is Devcon's 20-Ton, 30 minute setting one. .

- Q:I am a college student. Due to allergies, I have to cook more. I have a dorm with a kitchen. I'm just starting out.I was cooking some chicken and basically, I just tossed it on a pan with some oil and PAM. It was on low-medium heat.I put it in the pan and it cooked for a minute and then smoke began to rise. Not a lot, but it was noticeable. At this point, I turned the stove off, tossed the chicken on a plate, and then the smoke alarm went off for a few seconds before shutting off.Nothing has happened yet..I'm just really embarrassed and I hope no one finds out. I sprayed Lysol and opened the windows.Did I do something wrong? Now I am scared to even boil rice or noodles and stuff like that because of the smoke. Like I said, there wasn't a whole lot of smoke and it went off.

- Yes and no. It is certainly possible (and, indeed, easy) to perform home casting in resin. I've added a link below to one of the best online tutorials I've yet found. However, I do need to leap right in and point out that casting Warhammer models is an intellectual property violation and could land you in hot water. Sculpting your own stuff and casting that, or casting one or two pieces for a one-off conversion or diorama - that's fine. A popular use of resin casting techniques is to replicate sculpted miniature bases multiple times for an army. That's fine, too. But casting up GW models to avoid having to buy more of them is very illegal in the take you to court and fine the hell out of you, if not send you to gaol sort of way. Just so you know.

- Q:I have trouble getting up and set my alarm sometimes. But if I'm lucky, only once a week does it actually wake me up! And I have it on every day, and then I hit ok or whatever and then hours later when I wake up - I can't remember it! My brother told me he heard my alarm, saw me sit up and turn it off and then go back to sleep.It freaked me out at once because he said my moves were 'ghostly' like. Like I was possessed and didn't know what I was doing, but my mum reminded us that as a child I sleep walked and did these things, I remember sometimes because I'd wake up on the floor and stuff.But anyway, how can I make myself used to my alarm to actually get off my lazy a** and wake up instead of turning the alarm off?

- Probably sometime during this shield thing.

- Q:Anyone know a website who sells Face shield tear offs for motorcycle helmets? i know a lot of racing events use them. but any for just the normal everyday rider? cause im really tired of cleaning my face shield every other day. or any one know a good way to make some out of around the house stuff?

- braid your hair in two braids and put a hair tie at the ends and spray with hairspray and go to sleep with it like that and in the morning when you take the hair tie out your hair will be wavy..

- Q:Can water make a thinner of transparent resin that day?

- If you turn over the mold resin is used for other words, usually can be added in a small amount if more properties of the cured resins will reduce. The components of water are xylene + acetic ether + butanol +MEK standard, butanol can not and polyurethane and its curing agent isocyanate contact, will lead to chemical reaction failure.

- Q:Has anyone ever ordered from Poker 'n Stuff (pokernstuff )

- Dandelion has a great suggestion of how to prepare Benzoin (a little tricky because it is a resin), and I think she answers your question. I have also ordered it as a liquid absolute, which made my life allot easier The most common way that Styrax benzoin is used in aromatherapy is as a fixative and it helps keep the essential oils from evaporating to quickly. Essential oils have different rates of volatility; they evaporate ate different rates. Lemon oil that is very light will emit itself into the atmosphere quickly and is very volatile. Patchouli is slower and more dense. When you make a combination for therapeutic work, you don;t want the lighter essential oils to evaporate away and for you blend to stay stable. Add 5% benzoin to your formulas, and they will stay more consistent. It also has medicinal applications used topically for fungus skin irritation. Hope this addition info is helpful!

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu,China |

| Year Established | 1958 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Resin P500

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20Ton m.t.

- Supply Capability:

- 5000 Ton/Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords