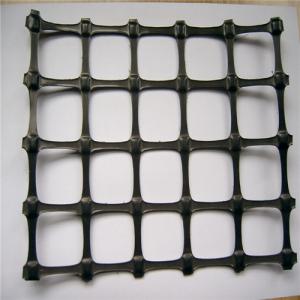

PP Biaxial/Unixial Geogrid Reinforcement

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP geogrid Description

PP geogrid is manufactured from polypropylene. It is produced through the process of extruding, punching, heating, longitudinal stretching and transverse stretching.

PP geogrid Specification

Tensile Strength: 15KN-15KN, 40KN-40KN, 50KN-50KN, etc

Roll Size: 3.95x100m, 2x50m, as request.

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

PP geogrid Property

1) Not easy to produce static after friction.

2) Good flame retardant performance.

3) Strong anti-corrosion and rust resistance.

4) High bearing capacity, low elongation.

PP geogrid Application

1) Coal mine channel.

2) Slope protection in tunnel and expressway.

3) Anti-seismic reinforcement of buildings.

FAQ

Q:Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

Q:What is your minimum order quantity?

A:The minimum order is negotiable.

Q:What is your payment terms?

A: T/T or L/C

Q: What is your delivery time?

A:Production time usually cost 7-15 days.

Q: Why we choose you?

We have up to 15 years experience of geogrid manufacture. best quality of product is guaranteed!

- Q:Can geogrids be used for load distribution?

- Yes, geogrids can be used for load distribution. Geogrids are specifically designed to distribute loads over a wider area, improving the stability and strength of various structures such as roads, retaining walls, and embankments. They help to spread the applied load more evenly, reducing the potential for localized stress and preventing the formation of cracks or failures.

- Q:Urgent need!!

- In the local municipal quota to look for, if not, then only by the actual market price in order to supplement the purpose of the form to supplement the input calculation. General municipal quota will have the corresponding sub purpose, you can look at.Fiberglass geogrid with glass fiber rovings as the main raw material, the reticular structure material of the knitting process, to protect and improve the overall use of polyester glass fiber geogrid with high strength aramid fibre filament, warp knitting weaving cloth after directional grid slab, geotechnical grille into coated processing.

- Q:What are the advantages of using geogrids in mechanically stabilized aggregate bases?

- Some advantages of using geogrids in mechanically stabilized aggregate bases include increased load-bearing capacity, improved stability and performance, reduced construction and maintenance costs, and enhanced longevity of the pavement structure. Geogrids distribute and restrain the applied loads more evenly, reducing the stress on the underlying soil and aggregate layers. This results in higher load-bearing capacity and improved resistance against settlement, rutting, and pavement deformation. Additionally, geogrids help in maintaining the integrity of the aggregate base by preventing lateral spreading and enhancing interlocking between the aggregate particles. The use of geogrids also reduces the amount of aggregate material required for construction, leading to cost savings. Moreover, the improved stability provided by geogrids can extend the lifespan of the pavement structure, reducing the need for frequent maintenance and repairs.

- Q:What are the load-bearing capacities of geogrids?

- The load-bearing capacities of geogrids vary depending on factors such as the type and quality of the geogrid, the soil conditions, and the specific application. Geogrid manufacturers typically provide technical data sheets specifying the load-bearing capacities of their products, which can range from a few kilonewtons to several hundred kilonewtons per meter. It is important to consult these specifications and conduct appropriate engineering analysis to determine the suitable geogrid and its load-bearing capacity for a particular project.

- Q:Are geogrids suitable for use in ground reinforcement for solar farms?

- Yes, geogrids are suitable for use in ground reinforcement for solar farms. Geogrids provide excellent soil stabilization, erosion control, and load-bearing capacity, which are crucial for supporting the heavy equipment and structures in solar farms. Additionally, geogrids can enhance the overall stability and longevity of the ground, ensuring efficient and sustainable operation of solar energy infrastructure.

- Q:What is the ultimate tensile strength of geogrid?Ask you

- Glass fiber grille without creepThe unidirectional geogrid has high strength (> 100kN/m) and tensile modulus in the tensile direction

- Q:Geocell of earthwork grid construction method

- 4, permafrost subgradeIn the construction of embankment in permafrost regions, should reach the minimum height of fill, to prevent the occurrence of frost or freezing layer caused by upper limit decreased, resulting in the occurrence of excessive settlement of embankment. The whole side reinforcing effect of geocell specific and effective implementation, to the maximum extent to ensure that the minimum height of fill in some special area, and the high strength and stiffness of soil.5, loess collapsibility roadbed treatmentFor the highway and the highway through the collapsible loess and loess compression lots better, or high embankment foundation and embankment load is lower than the vehicle to allow the weight bearing pressure, should also be in accordance with the requirements of the subgrade bearing capacity, then the geocell superiority will undoubtedly show the.6, saline soil, expansive soilThe saline soil, expansive soil and construction of the highway, a highway, the road shoulder and slope reinforcement measures are used, the reinforcement effect of geocell facade is a reinforcement material in all the best, and it has excellent corrosion resistance, can fully meet in saline soil, expansive soil has higher requirements for highway.

- Q:Can geogrids be used in temporary construction access mats for environmentally sensitive areas?

- Yes, geogrids can be used in temporary construction access mats for environmentally sensitive areas. Geogrids are a type of geosynthetic material that provides stability and reinforcement to the ground. They are often used in construction access mats to distribute loads and prevent soil erosion. Due to their low environmental impact and ability to protect the underlying soil, geogrids are suitable for use in environmentally sensitive areas where minimizing disturbance is crucial.

- Q:What are the factors that affect the installation and survivability of geogrids in harsh environments?

- There are several factors that can affect the installation and survivability of geogrids in harsh environments. Firstly, the type and quality of the geogrid material plays a crucial role. Geogrids made from high-strength polymers or synthetic fibers are more likely to withstand extreme conditions. Secondly, the design and installation techniques used are important factors. Proper anchoring, tensioning, and overlap of geogrids can enhance their durability in harsh environments. Additionally, the soil type and its characteristics, such as cohesion and friction angle, can impact the performance of geogrids. The presence of aggressive chemicals, temperature fluctuations, and exposure to UV radiation are other factors that can affect their survivability. Overall, a thorough understanding of these factors and adherence to best practices during installation are essential for ensuring the successful functioning of geogrids in harsh environments.

- Q:Can geogrids be used in reinforced earth bridge abutments in liquefaction-prone areas?

- Yes, geogrids can be used in reinforced earth bridge abutments in liquefaction-prone areas. Geogrids are commonly used as reinforcement materials in geotechnical engineering to improve the stability and strength of soil structures. In liquefaction-prone areas, where the soil becomes unstable and loses its strength during seismic events, geogrids can provide additional support and prevent potential failures in bridge abutments. By reinforcing the soil, geogrids help to distribute and resist the lateral forces caused by liquefaction, ensuring the stability and safety of the bridge abutments in these vulnerable areas.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Biaxial/Unixial Geogrid Reinforcement

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords