Refrigeration Copper Pipe R410A for Refrigeration System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

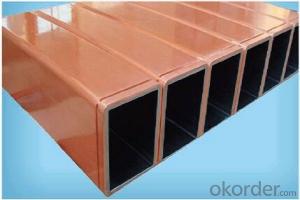

Refrigerant Copper Pipe Type R410A

Model: TP2、TU1、TU2、T2

Application:

Primarily applied in household and commercial central air conditioning system; pressure resistant product made by large water seal extruder through degrease process, without residual oil and with low dust load, suitable for refrigeration systems using new refrigerant

Type Specifications: TP2, TU1, TU2, T2

Primarily applied in household and commercial central air conditioning system; pressure resistant product made by large water seal extruder through degrease process, without residual oil and with low dust load, suitable for refrigeration systems using new refrigerant

Specifications:

Item | air conditioner copper pipe |

Type | straight copper pipe,pancake coil copper pipe,capillary copper pipe |

Standard | GB/T1527-2006,JIS H3300-2006,ASTM B75M,ASTMB42,ASTMB111,ASTMB395, ASTM B359,ASTM B188,ASTM B698,ASTM B640,etc |

Material | C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920, C10930,C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300, C12500,C14200,C14420,C14500,C14510,C14520,C14530,C17200,C19200, C21000,C23000,C26000,C27000,C27400,C28000,C33000,C33200,C37000, C44300,C44400,C44500,C60800,C63020,C65500,C68700,C70400,C70620, C71000,C71500,C71520,C71640,C72200,etc |

Shape | Round,Square,Rectangular,Oval,half-round |

Outside diameter | 4.76-28.58mm |

Wall thickness | 0.4-1.5mm |

Length | 1m,2m,3m,6m,or as required |

Hardness | 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard,soft,. |

Surface | mill,polished,bright,oiled,hair line,brush,mirror,sand blast,or as required |

Price Term | Ex-Work,FOB,CNF,CFR,CIF etc |

Payment Terms | TT,L/C etc |

Export to | Singapore,Indonesia,Ukraine,Korea,Thailand,Viet Nam,Saudi Arabia,Brazil,Spain,Canada, USA,Egypt,Iran,India,Kuwait,Dubai,Oman,Kuwait,Peru,Mexico,Iraq,Russia,Malaysia,etc |

MOQ | 2 tons |

Package | Standard export package ,or as required. |

Application | Copper pipe have strong, corrosion resistant properties, and become a modern contractor in all of commodity house pipes, heating, cooling water piping installation of choice |

Contact | If you have any question ,please feel free to contact me we are sure your inquiry or requirements will get prompt attention |

Production Equipment

750-1500kg main frequency induction copper melting furnace, 80MN water seal extruder, LG60 high speed two-roll cold pilger mill, straight-line wire-drawing machine, copper tube/pipe straightener, polisher, 84′ copper coil winding machine, straightening-cutting & pancake coiling machine, thermoplastic packaging machine, 1.2T continuous bright annealing furnace.

80MN extruder

Continuous bright annealing furnace

Testing Devices

spectrum analyzer, atomic absorption analyzer, spectrophotometry, analytical balances, metallurgical microscope, eddy current flaw detector, metal tensile testing machine, eddy conductivity instrument.

Hardness tester

Spectrum analyzer

Metallurgical microscope

Metal tensile testing machine

Atomic absorption analyzer

Process

refined copper — smelting & casting — extrusion — rolling — drawing — straightening-cutting/forming of pancake coil — bright annealing — packaging — finished goods.

Standards

GB/T 1527-2006 Drawn tube of copper and copper alloys

GB/T 16866-2006 Dimensions and tolerances of copper and copper alloy seamless tubes

GB/T 4423-2007 Copper and copper-alloy cold-drawn rod and bar

GB/T 5231-2001 Wrought copper and copper alloys chemical composition limits and forms of wrought products

GB/T 5585.1-2005 Copper or aluminium and its alloy bus bars for electrical purposes—Part 1:Copper andcopper alloy bus bars

GB/T 17791-2007 Seamless copper tube for air conditioner and refrigeration equipment

GB/T 19850-2005 The seamless round copper tubes for electrical purposes

GB/T 26024-2010 Seamless copper and copper alloys tube for valves on air-conditioning and refrigeration system

ASTM B280-2008 Standard Specification for Seamless Copper Tube for Air Conditioning and Refrigeration Field Service

EN 12735-1:2001 Copper and copper alloys Seamless,round copper tubes for air-conditioning and refrigeration Part 1:Tubes for piping systems

EN 12735-2:2001 Copper and copper alloy – seamless round copper tube/pipe for air-conditioning and refrigeration system – for equipment

JIS H3300-2009 Seamless copper and copper alloy tube/pipe

- Q:Can a hole (the diameter of pencil lead) in copper pipe be spot soldered to stop the leak?

- I've dabbeled in a little work that involved copper plumbing and every hole I've ever delt with be it the size of a pin head is repaired by working a new piece with a coupler on each end into the place of the damaged length. solder alone shouldn't be trusted at any pressure that focused. With the new couplers the pressure and stresses would be spread out over a much greater area. Also take into account what caused that hole if the forces causing it punched a hole in the copper solder wont stand a chance.

- Q:In my basement there is an unused plugged 6in pipe full of millions of very tiny balls, copper/orange in color (quite a bit smaller than a typical BB). They dont appear to be hollow or filled with anything, so i assume they are not spider/insect eggs. perhaps copper vein droplets? im not even sure what to google to begin searching for other options.

- Sounds like someone was in the process of making a pipe bomb. Turn it over to someone in law enforcement.

- Q:Is the gap between the copper tube and the galvanized pipe wide?

- In theory, there is little difference, but see where it is used.Galvanized pipe is generally steel pipe, galvanized surface is mainly used for anti-corrosion (rust). Copper pipe market is generally cold drawn copper tube, hardness of 3 kinds, the harder the more brittle. Therefore, the strength and hardness of galvanized pipe is certainly good, shaping is the most soft copper tube.

- Q:I just had the Paraguard IUD copper inserted about 2 days ago and I was spotting afterwards but now it looks like if I have my period blood like it got heavier I have to wear a pantyliner and I seen small clots but not like a ball only like thin pieces (maybe you know what I mean lol) but I was just wondering how long does this bleeding last. I just finished my period and now its like I started again! If anyone has the paraguard or people that have experience with this can answer thanks!

- The Paraguard IUD is copper based which means it can cause heavier periods with more painful cramps while your body adjusts. The Mirena IUD is hormone based and it's the Mirena that can give you shorter lighter periods. Sorry, read some of the other answers and wanted to clear that up for you. As for the Paraguard, and the Mirena actually, when they insert it there is some cervical trauma by virtue of how the device is fitted. So bleeding for a few days is perfectly normal. With the Paraguard, the copper can make the bleeding worse but it's still normal. I bled for quite awhile after mine was inserted. Nothing to worry about.

- Q:i want to know if when i do this reaction that the copper powder at the bottom of container is able to be sold for scrap or is there a way to melt the powder into sold copper or maybe electroplate it on to #1 copper wire maybe? any info with this will be cool thanks

- copper one or copper two? and which iron?

- Q:My 3 gallon air compressor sending pipe is broken. That pipe is a copper pipe itself but I think it is a hard one. Can I replace it with a soft copper pipe?

- This site lists the lowest bursting pressure of 1,400 psi. I don't know of a 3 gal air compressor that can generate that much pressure. Pressure washers are a different story. That pipe is probably 3/8 in, so the bursting pressure is probably about 5900 psi for Type K to 4200 psi for Type L soft annealed copper tube. More than likely, it's soft copper, not hard copper.

- Q:Well I know Copper pipe plumbing is bacteriostatic, and that bacteria can‘t grow in the copper pipeswhich means it‘s probly a lot safer than lead which made them sick and die quite a bit

- Yep, the lead would also rust and make lead oxide which is poisonous

- Q:Zinc metal reacts with copper(II) ion in solution to produce zinc ion and copper metal, as follows.Zn(s) + Cu2+(aq) ? Zn2+(aq) + Cu(s)You add 7.675 grams of Zn metal to 27.0 mL of 0.270 M CuSO4·5H2O and allow the reaction to proceed until the blue color of the solution is gone. You note that copper metal is plating out on the zinc pellets. How many moles of Zn have you added to the flask? (Unit is mol).How many moles of Cu2+ ion are in the solution? (Unit is mol).How many moles of Zn will have reacted with the Cu2+ when the reaction is complete? (Unit is mol).How many moles of Zn will remain unreacted? (Unit is mol).What mass of Zn will remain unreacted? (Unit is g).How many moles of Cu metal will be produced? (Unit is mol).What mass of Cu metal will be produced? (Unit is g).When the metal pellets are removed, dried, and weighed, what should be their total mass?

- Molar mass of zinc is 65.40 g/mol, of copper 63.546 (you can find that in a periodic table of elements). Amount of zinc equals n=m/M; 7.675 g/65.40 g/mol = 0.117 mol. Molar concentration (c=n/V) of CuSO4?5H2O is 0.270 mol/L, volume equals 27.0 mL = 0.027 L. Amount of CuSO4?5H2O equals 0.27 mol/L X 0.027 L = 0.000729 mol. Each mol of CuSO4?5H2O gives one mol of Cu2+ ions (CuSO4→Cu2+ + SO42-), so amount of Cu2+ ions in a solution is 0.000729 mol. One mol of Zn reacts with one mol of Cu2+ (Zn + Cu2+→Zn2+ + Cu), therefore 0.000729 mol of Zn reacted. 0.117mol (starting amount)-0.000729 mol (reacted amount) = 0.116 mol of Zn remained in a solution. That means 7.586 g of zinc remained (0.116 mol X 65.38 g/mol). One mol of Zn reacts with one mol of Cu2+, therefore 0.000729 mol of Cu is produced, which is 0.046 g. Total mass of pellets (copper coated zinc) is (starting mass of zinc – mass of reacted zinc) + mass of produced copper: 7.586g Zn + 0.046 g Cu = 7.63 g.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refrigeration Copper Pipe R410A for Refrigeration System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords