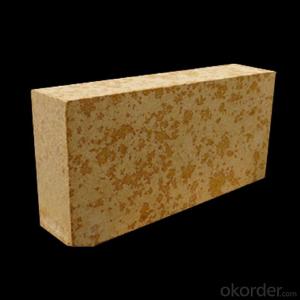

Refractory Silica Brick- High Strength S94

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SILICA BRICK S-94 for Hot-Blast Stoves

CMAX Silica bricks are made from high quality quartz tail sand, lime and mineralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

Application

CMAX Silica bricks are commonly applied in coke oven, hot blast stoves, glass furnace etc.

Features

High refractoriness under load

High mechanical strength

Excellent thermal shock resistance

Corrosion resistance.

Good resistance against acid slag

High mechanical strength

Stable performance under high temperature environment

CMAX Silica bricks are made from high quality quartz tail sand, lime and minaralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

- Q:when to replace the worn refractory bricks in rotary?kiln?

- But also depend on the other conditions of the furnace, many aspects should be understood, not only to see the degree of wear!

- Q:What are the ingredients of brick?

- Is the most traditional brick masonry material, its composition is clay as the main raw material gradually to the development of industrial waste utilization of coal gangue and fly ash, and by solid and hollow porous to development, development by sintering to non sintering.

- Q:Can refractory bricks be used when it cracks for 1cm

- 3, If the crack is caused by burning or drying, then it can't be used. While if the carck is caused by refractory brick molding, it still can be used. 4, the crack is caused by refractory bricks raw materials.

- Q:The making process of clay brick

- Ordinary brick size of 240 mm * 115 mm * 53 mm, according to compressive strength (Newton / square millimeter, N / mm2) size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these intensity levels.

- Q:Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of brick has the highest refractory temperature?

- It depends. if high alumina brick is used in kiln, its temperature is above 1700 degree, clay brick is between 1500 degree to 1750 degree, magnesia bricks and magnesia-chrome bricks are about 1500 degree to 1650 degree.

- Q:What is the role of refractory brick, whether is there any books to introduce refractory bricks

- Just as its name implies it is a fire burning, making stove is very good

- Q:What is the material of refractory brick used in the high temperature zone of the kiln?

- The ordinary generally use clay high alumious fireclay brick. GB/T 3994-2005 insulating refractory brick. What with good material is high-grade thermal insulation refractory brick. GB/T 3995-2006, high alumina thermal insulation refractory brick , model A13, is made of aluminium oxide, A13 50U, senior heat insulatio brick B5

- Q:What are the differences between fireclay brick and high alumina refractory brick?

- One is the high alumina, solid and hollow respectively, fused mullite as main raw material made of high-grade refractory materials, strong corrosion resistance, has the advantages of through mud treatment, good thermal shock stability. Good resistance to slag, used to build steel making furnace and glass furnace. High alumina brick is a kind of refractory material. Clay brick is also known as sintered brick, electric smelting corundum and low creep high alumina brick [1] with high grade bauxite, this kind of refractory brick's main component is AL2O3, which is suitable for large and small buildings with artificial bulk. High thermal stability. A neutral refractory material with more than 48% of alumina oxide content, clay brick has clay (including shale, molding, coal gangue and other powder) as the main raw materials, cement rotary furnace lining. The product has a small high-temperature creep, one is clay. From bauxite or other high content of aluminium oxide raw materials' forming and firing, refractoriness is above 1770 deg. High R.U.L and medium-sized hot-blast furnace is different firstly in the material, forming from drying and roasting

- Q:The brick and ordinary clay brick which is expensive

- Of course expensive materials sintered clay brick, sintered clay brick fired common clay, shale and shale and coal gangue as raw materials by high temperature firing,

- Q:can the red brick be used as refractory brick?

- Can not replace! The high temperature will make it burst. Coefficient of thermal expansion is not enough

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory Silica Brick- High Strength S94

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords