REFRACTORY MATERIAL Ceramic Fibre Blanket for Fireplace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

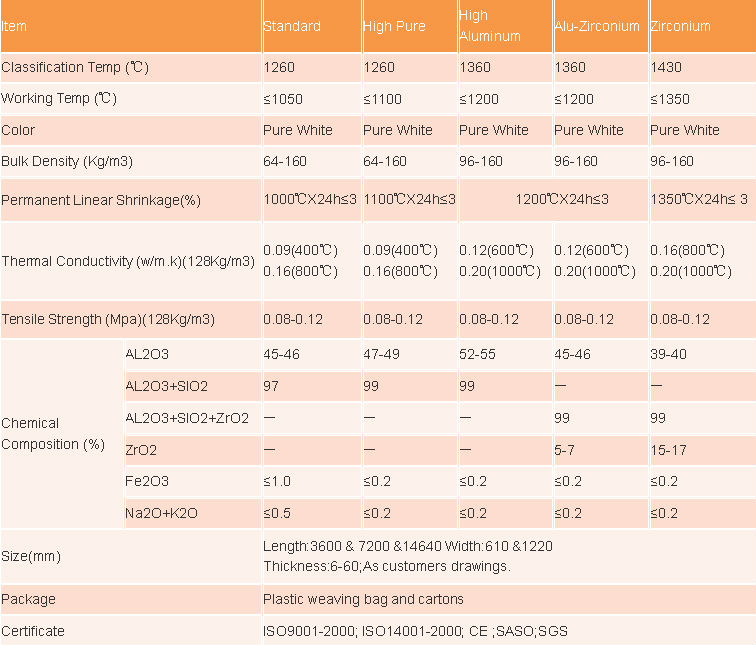

Technical Data of Ceramic Fiber Blanket

Remarks: The data above is for reference. The Max. temperature depends on the using conditions.

Product Description:

CeramicLooseFiberis made by the melted raw materials at high temperature through resistance furnace, before being blown or spun into fiber. As a neutral and acidic material, except reaction with the strong acid-alkali,refractoryceramic fiber won’t be eroded by other weak alkali, weak acids, or water, oil, steam, or be infiltrated with lead, aluminum or copper, featuring excellent flexibility and elasticity. Ceramic fiber is of smaller density, more than 75% lighter than insulation brick lining or 90% -95% lighter than lightweight castable lining, with thermal conductivity co-efficient to be 1/8 of the lightweight clay brick or 1/10 of lightweight heat-resistant lining (castable), and heat capacity to be 1/10 of both lightweight insulation lining and lightweight castable lining, thus to greatly lower energy loss and deliver significant energy-saving regenerative effects. Meanwhile, the ceramic fiber features a simple construction with no need of baking oven, shortened construction cycle and easy installation.

Low heat capacity and low thermal conductivity;

Excellent chemical stability;

Excellent thermal stability, resistance to pulverization at high temperature;

With no binders or corrosive substances;

Excellent sound absorption

Typical Application:

Raw material for fiber blanket, board products;

Raw material for fiber textile products;

Fillings for wall lining gap in high temperature furnace, heating device;

Raw material wet processed products;

Fiber spraying;

Castables;

Raw material for coatings;

Insulation fillings for corner and complex space.

- Q:What is the function of glass wool foil?

- Possessing strong resistance to thermal radiation, glass wool with aluminum foil veneer is excellent lining material for high temperature workshops, control rooms, walls of machine room, compartment and flat top.Aluminum foil veneer is pleasing to the eye and moistureproof.Glass wool is one kind of the glass fiber and it is a man-made inorganic fiber. Glass is made by melting such raw materials as quartz sand, limestone, dolomite and other natural ore with some chemical materials like pure alkali and sodium borate. In the molten state, the glass is thrown into fine fibers in the shape of floc by the with external force. These fibres vertically interwine and show many small gaps. These gaps can be regarded as air void. Thus, glass wool can be regarded as porous materials and it is of good insulation and sound absorption performance.

- Q:What are the advantages and disadvantages of centrifugal glass wool?

- Centrifugal glass wool board is fiber product, so human body will be allergic, whose temperature endurance is 400 degrees with good thermal insulation effect, mainly used in buildings and underground pipes.

- Q:what is the specification of glass wool sound-absorbing board?

- General specifications include 600 * 600600 * 500 * 1200-1200/12000300/400 mm thickness is usually 14 to 22 mm. . But different production capacity depends on the specific manufacturer, the manufacturer without certain production capacity can't do the bar plate or reach the thickness.

- Q:Are there any differences between glass wool and rock wool in terms of appearance, I can't distinguish them, why?

- They have different colors

- Q:How is the insulation property of glass wool color steel?plate?

- It has poor insualtion property but good firepoof property. Rock wool insualtion board is recommended.

- Q:What is the difference between red glass wool and yellow glass wool in terms of technical parameters?

- Thermal insulation properties: Red yellow glass VS Yellow glass wool. Thermal conductivity (K): below 0.039 VS over 0.044; Resilience: good VS poor. Distribution: even VS uneven. Irritation: non-irritating VS irritating and cause itching of skin. Dust: without dust VS with dust. Shot content: zero VS non-zero. Red glass wool is an environmental-friendly material.

- Q:What is the difference between glass wool and rock wool?

- What is the difference between glass wool and rock wool?

- Q:How to conduct thermal insulation construction of external wall glass wool?

- Construction recommendations: Installing metal frameworks in the floor and in their corresponding roof, trying to ensure that the framework should be perpendicular to the floor; erecting metal framework in the location apart 60cm from the metal frameworks that have been placed; pasting gypsum board on one side of the frameworks and fix it to the frameworks; putting glass wool in the gap of frameworks; pasting gypsum board on the other side of the frameworks.

- Q:What are the hardnesses of rock wool and glass wool respectively? Are there any requirements on saw blade?

- Almost the same. It should be used universally.

- Q:Which is more suitable for industrial pipe insulation: glass wool or rock wool ?

- Glass wool, now rock wool seems to be out of date.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

REFRACTORY MATERIAL Ceramic Fibre Blanket for Fireplace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords