Refractory JM Mullite Insulation Brick B-5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Low density.

2. Classification temperature:1610-1780.

3. Thermal insulation energy-saving effect is good.Refractory mullite insulating refractory brick JM 23

Okorder series heat insulation brick

Okorder series thermal insulation brick is an effective, energy saving, low carbon, environmental protection advanced, according to the ASTM standard manufacturing products. Okorder series products are best Li Ning and insulation in all types of industrial furnaces in the metallurgical field, aluminum, petrochemical, electric power and glass ceramic materials. They can be used as part of the working layer of thermal insulation or non - melting. Products have been widely used in the following furnace, achieved satisfactory results.

Application of heat preservation brick

Metallurgical Industry: blast furnace, hot blast furnace, heating furnace, etc..

Petrochemical Industry: ethylene cracking furnace, hydrogen production furnace, primary reformer, heating furnace, etc..

Ceramic industry: roller kiln, kiln, etc..

Glass industry: glass furnace regenerator, etc.

Carbon industry: carbon furnace, etc..

Aluminum electrolysis industry: aluminum reduction cell, etc.

Other industries: tunnel kiln, shuttle kiln, etc..

Advantages of heat insulation brick

Low thermal conductivity: more porosity will bring good thermal insulation effect, energy saving.

High crushing strength: high crushing strength, volume stability.

Low heat storage: small heat storage to absorb more heat, energy-saving effect is obvious.

Gao Chundu: iron, alkali metal impurity content is low.

The precise size: Brick size processing precision, special shape cutting and grinding, accelerate the brickwork.

Insulating brick picture

Common problem solutions

1. What products do you have?

We have all kinds of refractory bricks, refractory casting materials, mortar, cement, ceramic fiber products, etc..

Or you can browse our products to choose what you need.

2. How to control product quality?

With strict quality control system throughout the material selection and production process, we have the quality of refractory materials and ceramic fiber products to meet customer requirements.

From the selection of raw materials, the quality of our control to start. The quality certificate of the raw material is required, each batch of the products are to be tested in the use of the forward line. In the production process, the quality control by the workers, and then each piece of classification, and through the quality supervision and inspection.

3. Can you give me a brief introduction to the application of your product?

My company is mainly engaged in refractories in the steel, cement, glass, ceramics, petrochemical, electric power and other industries.

4. What information do you need if I need you?

In order to select the right products, we will provide us with information, such as the United States, technical data, order quantity, product application, etc..

If you have any questions, please contact us.

High alumina insulation brick,Insulation brick,Fireclay insulation brick

Features:

1. Low thermal conductivity.

2. High strength and resistance to corrosion.

3. Low heat capacity.

4. Low shrinkage after heavy firing.

5. High insulation.

6. High refractoriness.

7. Low density.

8. Good thermal shock resistance under high temperature.

9. Thermal insulation energy-saving effect is good.

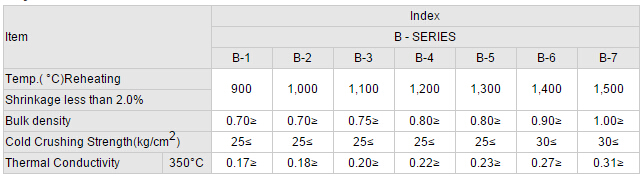

Physical and chemical index:

Application:

Insulation brick can be widely used for lining or insulation layers of various industrial furnaces and kilns in metallurgical industry, machine building industry, ceramic industry, chemical industry.

- Q:What is the typical thermal shock resistance of an insulating fire brick?

- The typical thermal shock resistance of an insulating fire brick can vary depending on the specific composition and manufacturing process. However, in general, insulating fire bricks are designed to have high thermal shock resistance. These bricks are often made from lightweight materials such as alumina, silica, and other refractory compounds, which possess excellent thermal insulation properties. Insulating fire bricks are engineered to withstand rapid temperature changes without cracking or breaking. They can typically endure thermal shocks caused by sudden exposure to extreme heat or cold, as well as rapid heating or cooling cycles. The thermal shock resistance of insulating fire bricks is crucial in applications where they are exposed to fluctuating temperatures, such as in furnaces, kilns, and other high-temperature environments. While there is no universally standardized value for the thermal shock resistance of insulating fire bricks, they are typically designed to withstand thermal shocks of several hundred degrees Celsius without significant damage. Some high-quality insulating fire bricks can even tolerate thermal shocks of up to 1000°C or more. It is important to note that the specific thermal shock resistance of an insulating fire brick might also depend on factors such as the brick's thickness, density, and overall quality. Therefore, it is advisable to consult the manufacturer's specifications or conduct specific tests to determine the exact thermal shock resistance of a particular insulating fire brick.

- Q:Are insulating fire bricks resistant to carbon dioxide?

- Insulating fire bricks, also known as refractory bricks, are engineered for withstanding high temperatures and displaying resistance to various chemicals and gases. Nonetheless, the level of resistance to carbon dioxide may differ based on the particular type and composition of the insulating fire brick. Carbon dioxide (CO2) is an inert gas usually found in the atmosphere and released when carbon-based fuels are burned. Typically, insulating fire bricks exhibit high resistance to carbon dioxide due to their elevated melting point and the presence of refractory materials like alumina and silica. Nevertheless, extended exposure to high concentrations of carbon dioxide, especially at increased temperatures, may lead to chemical reactions in some insulating fire bricks, resulting in degradation or diminished performance. Therefore, it is crucial to consider the specific application and environment in which the insulating fire bricks will be utilized. If the insulating fire bricks are part of a furnace or kiln that generates substantial amounts of carbon dioxide, it is advisable to select bricks explicitly designed for such conditions. These bricks might possess additional protective coatings or enhanced chemical resistance to ensure their durability and performance. To summarize, although insulating fire bricks generally possess good resistance to carbon dioxide, it is imperative to consider the specific type of brick and the conditions in which it will be employed to guarantee optimal performance and durability.

- Q:Do insulating fire bricks require any special firebrick mortar for installation?

- Yes, insulating fire bricks do require a special firebrick mortar for installation. Regular mortar is not suitable for insulating fire bricks because it may not provide the necessary thermal insulation properties or withstand the high temperatures that these bricks are designed to handle. Insulating firebrick mortar is specifically formulated to withstand extreme temperatures and to bond well with insulating fire bricks. It is typically made from a combination of refractory materials, such as high-alumina cement, silica sand, and fire clay. Using the correct firebrick mortar is crucial to ensure a strong and durable installation of insulating fire bricks.

- Q:Can insulating fire bricks be used for kiln furniture?

- Yes, insulating fire bricks can be used for kiln furniture. Insulating fire bricks are designed to withstand high temperatures and are commonly used in industrial kilns and furnaces. They have excellent thermal insulation properties, which makes them ideal for creating kiln furniture such as shelves, posts, and supports. The insulating properties of these bricks help to distribute heat evenly throughout the kiln, ensuring that the items being fired are heated consistently. Additionally, insulating fire bricks are lightweight and easy to handle, making them a convenient choice for kiln furniture.

- Q:Can insulating fire bricks be used in ceramic kilns?

- Yes, insulating fire bricks can be used in ceramic kilns. These bricks are designed to have high insulating properties, making them ideal for maintaining heat within the kiln. They are lightweight and can withstand high temperatures, making them a suitable choice for ceramic kilns.

- Q:Do insulating fire bricks require a protective coating?

- No, insulating fire bricks do not require a protective coating. They are designed to be used in high-temperature applications and are already resistant to heat, making them suitable for use without any additional coating.

- Q:Can insulating fire bricks be used in thermal power plants?

- Yes, insulating fire bricks can be used in thermal power plants. Insulating fire bricks are designed to provide thermal insulation and resist high temperatures, making them suitable for applications in thermal power plants. These bricks can be used in various areas of a power plant, such as in the lining of boilers, furnaces, and kilns, where they help to reduce heat loss and increase the overall energy efficiency of the plant. Additionally, insulating fire bricks are lightweight and have good thermal shock resistance, allowing them to withstand the extreme temperature fluctuations that occur in power plant operations.

- Q:Can insulating fire bricks be used for insulation in refractory lining repair?

- Indeed, insulation in refractory lining repair can be achieved by utilizing insulating fire bricks. Crafted from lightweight materials, these bricks boast exceptional thermal insulation properties, rendering them perfectly suitable for employment in high-temperature settings like furnaces, kilns, and other refractory lining structures. Their low thermal conductivity and impressive resistance to thermal shock enable them to effectively insulate and safeguard the refractory lining against heat, thereby averting heat loss and diminishing energy consumption. Additionally, the installation and replacement of insulating fire bricks are effortless, solidifying their position as a cost-efficient alternative for refractory lining repair.

- Q:Can insulating fire bricks be used in fireplaces?

- Yes, insulating fire bricks can be used in fireplaces. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation, making them suitable for use in fireplaces. They are capable of withstanding temperatures up to 3000°F (1650°C), which is well within the operating range of most fireplaces. These bricks are made from special materials that have low thermal conductivity, allowing them to retain heat and prevent it from escaping the fireplace. This insulation property helps to improve the efficiency of the fireplace by keeping the heat inside the firebox and preventing it from dissipating into the surrounding area. Additionally, insulating fire bricks are lightweight, durable, and easy to install, making them a popular choice for fireplace construction or renovation projects.

- Q:Are insulating fire bricks resistant to reducing atmospheres?

- Insulating fire bricks exhibit resistance to reducing atmospheres. These bricks have been specifically engineered to endure elevated temperatures and harsh circumstances, including exposure to reducing atmospheres. They are crafted from top-notch refractory materials that possess the capability to withstand the detrimental effects of reducing atmospheres, which may encompass gases like carbon monoxide or hydrogen. Due to their low thermal conductivity and superior insulation properties, insulating fire bricks prove to be exceptional in scenarios where reducing atmospheres are present. They efficiently shield the surrounding areas from heat transfer and safeguard the structure against potential harm. Furthermore, these bricks boast remarkable mechanical strength and outstanding resistance to thermal shock, enabling them to retain their integrity even in the face of challenging conditions. In conclusion, the durability of insulating fire bricks coupled with their capacity to endure high temperatures and harsh environments confirms their resistance to reducing atmospheres.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory JM Mullite Insulation Brick B-5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords