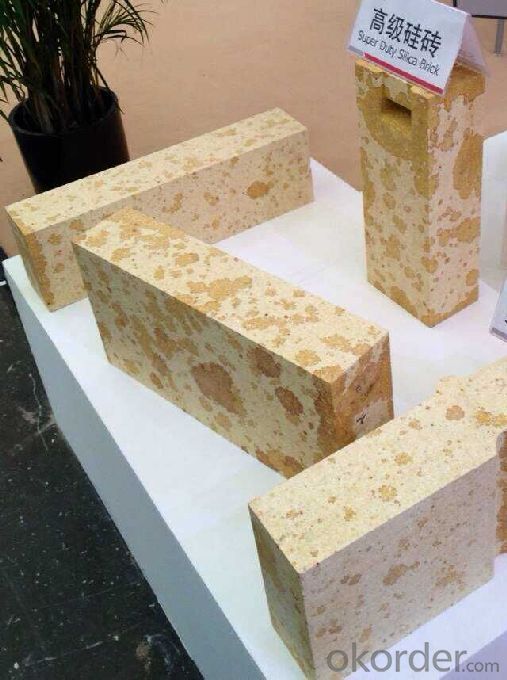

Refractory High Density Silica Brick 96B

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information:

CMAX brand Silica bricks are made from high quality quartz tail sand, lime and mineralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

Features of Refractory silica bricks for Glass Kiln:

1. high volume density of 2.34 g/cm3

2. high SiO2 content of 96%

3. low iron content of 0.8%

4. low melting point of 5%

Applications of Refractory silica bricks for Glass Kiln:

Because of the high temperature resistant performance significantly, long service life characteristics (as long as more than eight years) of refractory silica brick for Glass Kiln, it can significantly improve the quality of glass, so the refractory silica bricks are widely used in all kinds of glass furnace melting department, regenerator and other important parts.

Physical and chemical index of refractory silica bricks for glass kiln:

Item Brand | CMAX-96A | CMAX-96B | ||

SiO2 % ≥ | 96 | 96 | ||

Al2O3+2(K2O+Na2O) % ≤ | 0.5 | |||

Fe2O3 % ≤ | 0.8 | 1 | ||

Refractoriness °C ≥ | 1710 | 1710.0 | ||

0.2MPa Refractoriness under load °C ≥ | 1680 | 1670 | ||

Apparent porosity % ≤ | Brick with weight no less than 20kg | 20 | 20 | |

rick with weight less than 20kg | 22 | 22 | ||

CS MPa ≥ | 35 | 35 | ||

Bulk desity g/cm3 ≤ | 2.34 | 2.34 | ||

Starndard Size:

230*114*64mm

230*114*76mm

- Q:How to distinguish the fire?rating of rubber and plastic thermal insulation material?

- According to GB 8624-2006 "building materials and combustion products classification", the division of the material's combustion performance grade is changed from five levels of level A (homogeneous material), A (composite sandwich material), B1, B2 and B3 to seven levels of A1 , A2, B, C, D, E and F or A1f1, A2f1, Bf1, Cf1, Df1, ef1 and Ff1 or A1L, A2L, BL, CL, DL, EL and FL . The level B1 rubber and plastic fireproof and thermal inuslation matertial is the best, but the most commonly used one is level B2. Hope it will help you.

- Q:What's the feature of construction external wall fireproof and thermal inuslation matertial?

- Building external wall fireproof thermal insulation material is made by stirring, casting, foam protecting and cutting with industrial by-product gypsum as the main raw material, adding sulphate aluminium cement, fly-ash, polymer additives and other materials. It has excellent properties of respiratory function , air permeability, water impermeability, recycling system data, wind load resistance, shock resistance, thermal insulation, fireproof and sound insulation.

- Q:Ask some questions about refractories

- Application: it is suitable for blast furnace tapping system.

- Q:Which industry does refractory belong to? Does it belong to construction industry?

- I am engaged in construction. Refractory material does not necessarily belong to construction industry. Fire resistance is only a part of material?performance. Indeed, there are many places requiring refractory accorded with fire resistant level.

- Q:how to use boiler fireclay

- Boiler refractory, diluted with water to touch the places where needed, can be used after high temperature baking.

- Q:What is the fireproofing requirements of external wall thermal insulation materials?

- External wall thermal insulation materials fire rating regulations, 1, the height of a building is greater than or equal to 100m , the combustion performance of insulation materials should be level A; 2, the height of a building is greater than or equal to 60m but less than 100m, the combustion performance of insulation materials should not be less than the level B2. When using level B2 thermal insulation material, every layer should set horizontal fire barrier zone 3,The height of building is be equal or greater than 24m but less than 60m, the combustion performance of thermal insulation material should not be less than the level B2. When using level B2 insulation material, each two-layer should set fire barrier zone ; 4, the height of building is less than 24m, the combustion performance of insulation materials should not be less than the level B2. Besides, when using level B2 thermal insulation material, each three-layer should set a horizontal fire barrier zone.

- Q:Who knows the external wall thermal insulation materials fire rating requirements?

- 1. The thermal insulation material of level A combustion performance: Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3, combustion performance is level B2 insulation material: Molding polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. See the 2009 edition construction technical measures 4.3.6 Level A insulation material is only for fireproofing, but its thermal insulation performance is not better than organic XPS \\ EPS and other materials. I feel the best insulation materials should be modified phenolic board, which can keep insulation and fireproofing, but the unit price is very expensive. Insulation materials in the domestic market have some disadvantages, it is better to considere the materials within the acceptable range in the building needs.

- Q:Why the corundum can be used as refractory

- Do you need white corundum Its main chemical element of corundum is the 99.3% aluminium oxide and it is sintered byelectric furnace, so it can be used as a refractory raw material, the other can also be used as grinding wheel. It is very useful

- Q:hat kind of fire retardant materials are there

- There are many flame retardant plastics, which are modified on the basis of raw materials, such as flame-resistant ABS, flame-resistant HIPS, flame-resistant PP, flame-resistant PE, flame-resistant the PET, flame-resistant PBT, flame-resistant PC, flame-resistant PC/ABS alloy. Now there are mainly halogen flame retardant, though there are a lot of researches about halogen free flame retardant, the product stability and flame retardant effect remain to be improved. Testing methods of flame retardant materials are mainly: horizontal and vertical combustion, oxygen index method, NBS smoke box , thermal analysis, cone calorimeter, etc.

- Q:Does the refractory material used in steelmaking all refer to refractory brick?

- For example, refractory castable doesn't only refer to refractory brick, but also some bulk material and ramming?mass. Desulfurizer belongs to ferrous metallurgy auxiliary material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory High Density Silica Brick 96B

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords