Refractory Grade Calcined Bauxite for Alumina Cement

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Grade Calcined Bauxite for Alumina Cement

Calcined Bauxite Introduction

Property | Specifications |

Name | aluminous soil ; bauxite |

Color | White, offwhite, auburnish yellow or light red (with Fe) |

Bulk Density | 2.55~3.6 g/cm3 |

Hardness | 1~3 |

Main usages | 1. Aluminium metallurgy 2.Refractory |

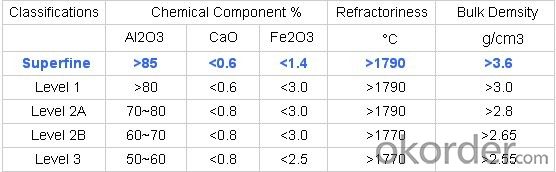

Calcined Bauxite Specifications

Calcined Bauxite Applications

1. Aluminium metallurgy

2. Precision casting / Investment casting:

bauxite grog fines can be made into mold for precision casting.

3. Refractory: high alumina bauxite’s refractoriness can reach 1780°C.

It is charactered by good chemical stability and mechanical performance. (Al2O3 ≥48% with low Fe2O3)

4. Aluminium silicate refractory fiber: The high alumina bauxite grog can melt under 2000°C-2200°C in the electric arc furnace.After a series of processing, it can become aluminium silicate refractory fiber,

which can be made into fiber blanket, plate,cloth.

5. Mixing magnesia and bauxite grog with binders to pour the molten steel ladle for better overall lining

performance.

Usage

1) The bauxite for aluminum industry in defense, aerospace, automotive, electrical, chemical, and daily supplies;

2) Bauxite clinker processed into fine powder and made after the casting mold. Used in military, aerospace, communications, instrumentation, machinery and medical equipment sector;

3) The bauxite can be used in refractory products. The refractoriness of high-alumina clinker is up to 1780 . Its features are chemical stability strong, and physical properties of sound;

4) It can manufact alumina cement, abrasive materials and aluminum compounds.

Pictures:

Remarks:

1) If you have special requirement for the specifications, we can have a talking to know if we can meet it. Usually, our skills and equipments are no problem. It's up to the production cost related to the bauxite raw ores we purchase;

2) Wide sizes variety is available as per customer's request.

- Q:What is neutral refractory? Can refractory suppliers tell the main components of it?

- The material using Al2O3, clay, bauxite and corundum as the main components is neutral material; the material using MgO and CaO as the main components is basic material; the material using SiO2 as th emain component is acidic material.

- Q:Introduction to refractory material

- The best way to learn is on-site contact. If for produing purpose, it is better to ask teh leader of a plant. If for application, go to steel mill (cement plant, glassworks, etc.) to learn and look up information. Theory alone is of no help.

- Q:Which fire-resistant materials have good viscidity?

- Viscidity is necessary for gunning mix, repair mix and bordering. It is too broad to which has good viscidity. Both gunning mix and repair mix are powder before adding water. Bordering also has little viscidity before heating. The question shoule be more specific.

- Q:What are the types of advanced refractory?

- Divided into ordinary and special refractory two categories. Common refractories by chemical properties into acidic, neutral and alkaline. Special refractory are divided by the high temperature oxide, refractory compounds and high-temperature composite materials by its compositions. according to refractoriness it can be divided into ordinary refractory products (1580 ~ 1770 ℃), advanced refractory products (1770 ~ 2000 ℃) and premium refractory products (2000 ℃ above). The article can be divided into blocks (standard bricks, shaped bricks, etc.), special shape (crucible, sagger, pipe, etc.), fibrous (aluminosilicate, zirconia and boron carbide quality, etc.) and irregular shape (refractory clay, pouring materials and ramming mixes, etc.) According to the sintering process is divided into sintered products, cast products, melt blown products. The appearance is shaped or amorphous according to pH it can be divided into acidic, neutral and alkalinity according to basic operation mode, there are castable refractory ramming spraying materials, impressionable plastic material, coating. according to different components, there are clay, high alumina, corundum, spinel, magnesia, magnesium, calcium, magnesium aluminum quality,magnesia-chrome, silicon, etc.

- Q:What type of firebrick does TZ-3 represent?

- Height is 65mm, length is 230mm, and width is 114mm, that is the t-3 firebricks which meet the national standard.

- Q:what's the materials of fireproof?housing?

- there are mainly several fireproofing levels, it is divided into flame retardant and non-combustible! at present t the main fireproofing materials on the market are made from rock wool board! it is incombustible?material, of course, the price is relatively high. Other common materials are fire?retardant foam.

- Q:I wanna ask you, which level is b1 fireproof and thermal inuslation matertial ??

- What you said is the pixel! Only that has b1b2. Level b1 is the fireproofing level b1, because the particle does not belong to the fireproofing material. Only can fire?retardant. The wholesale of all kinds of thermal insulation material and construction need to look at the name.

- Q:hat kind of fire retardant materials are there

- There are many flame retardant plastics, which are modified on the basis of raw materials, such as flame-resistant ABS, flame-resistant HIPS, flame-resistant PP, flame-resistant PE, flame-resistant the PET, flame-resistant PBT, flame-resistant PC, flame-resistant PC/ABS alloy. Now there are mainly halogen flame retardant, though there are a lot of researches about halogen free flame retardant, the product stability and flame retardant effect remain to be improved. Testing methods of flame retardant materials are mainly: horizontal and vertical combustion, oxygen index method, NBS smoke box , thermal analysis, cone calorimeter, etc.

- Q:What kind of material is refractory fiber?

- Refractory fiber, also known as ceramic fiber, is a fibrous thermal insulation refractory. Refractory fiber, also known as ceramic fiber, is a fibrous thermal insulation refractory. It has the characteristics of ordinary fibers, such as softness, flexibility, having a certain tensile strength. And it can be further processed into a variety of products such as paper, wire, rope, tape, blankets and felts. Besides, it has high temperature resistance and corrosion resistance which ordinary fibers don't have. As a fire retardant and thermal insulated material, it has been widely used in metallurgy, chemical, machinery, building materials, shipbuilding, aviation, aerospace and other industrial sectors.

- Q:What are the materials of insulation firebricks?

- The raw materials of firebricks, firebricks have various raw materials, and the composition of which can be divided into six categories: soil, stone, sand, mineral, powder and others. One of the raw materials, soil: bauxite, kaoline, clay, diatomite Another raw material, stone: fluorite, kyanite, andalusite, forsterite, vermiculite, mullite, pyrophyllite, chlorite, dolomite, sillimanite, magnesia-alumina spinel, and silica Another raw material, sand: clay sand, zircon sand, quartz sand, and magnesite Another raw materials, mineral: chromium mineral Another raw material, powder: aluminum powder, micro-silica powder, and silicon powder Another raw materials, others: asphalt, graphite, phenolic resin, perlite, cenosphere, sialon, corundum, silicon sulfate, silicon carbide, sodium silicate, silica sol, boron carbide, calcium aluminate cement, nitride material, haydite, aluminum oxide, alumina sol and zirconia, etc.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory Grade Calcined Bauxite for Alumina Cement

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords