Refractory Grade Calcined Bauxite 85% 0-5mm Sands

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Grade Calcined Bauxite 85% 0-5mm Sands

Calcined Bauxite Introduction

Property | Specifications |

Name | aluminous soil ; bauxite |

Color | White, offwhite, auburnish yellow or light red (with Fe) |

Bulk Density | 2.55~3.6 g/cm3 |

Hardness | 1~3 |

Main usages | 1. Aluminium metallurgy 2.Refractory |

Calcined Bauxite Specifications

| Al2O3% | CaO % | Fe2O3% | refractoriness | bulk density |

| >88 | <0.4 | <1.5 | >1790 | >3.15 |

| >85 | <0.6 | <1.8 | >1790 | >3.10 |

| >80 | <0.8 | <2.0 | >1790 | >3.0 |

| 70-80 | <0.8 | <3.0 | >1790 | >2.8 |

| 60-70 | <0.8 | <3.0 | >1790 | >2.65 |

| 50-60 | <0.8 | <3.0 | >1770 | >2.45 |

Calcined Bauxite Applications

1. Aluminium metallurgy

2. Precision casting / Investment casting:

bauxite grog fines can be made into mold for precision casting.

3. Refractory: high alumina bauxite’s refractoriness can reach 1780°C.

It is charactered by good chemical stability and mechanical performance. (Al2O3 ≥48% with low Fe2O3)

Usage

(1) aluminium industry. Used in national defense, aerospace, automotive, electronics, chemical industry,

daily necessities, etc.

2 precision casting. Alumina clinker made after the mould precision casting processed into fine powder.

Used in military industry, aerospace, communications, instrumentation, machinery and medical equipment department.

(3) is used for refractory products. High bauxite clinker refractoriness is as high as 1780, chemical stability strong,

and good physical properties.

(4) aluminum silicate refractory fiber. With light weight, high temperature resistance, good thermal stability,

low thermal conductivity, heat capacity is small and the advantages of resistance to mechanical shock.

Used in iron and steel, nonferrous metallurgy, electronics, petroleum, chemical, aerospace, atomic energy,

defense and other industries.

(5) in magnesia and bauxite clinker as raw materials, add the appropriate binder,

used for pouring ladle whole ladle lining has particularly good effects.

(6) manufacture alumina cement, abrasive materials,

ceramic industry and chemical industry can be aluminum of various compounds

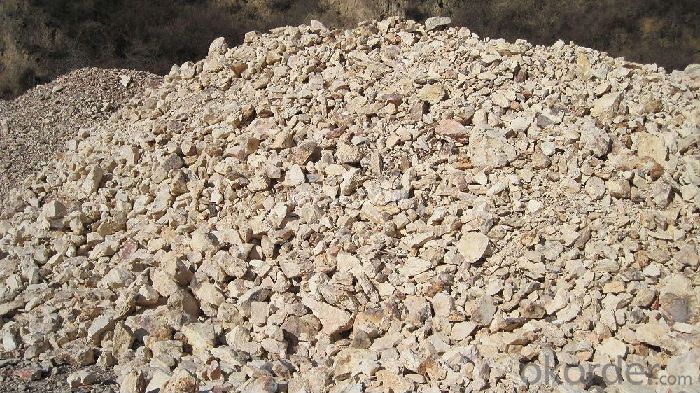

Pictures:

- Q:What things and cement mixed can act as refractory?

- Cement building, portland cement, refractory grade, calcium aluminate. Cement acts as refractory need to use calcium aluminate cement.

- Q:What is the biggest difference between refractory bricks and clay refractory bricks? Where can I find information on the refractory bricks?

- You can look up knowledge manual of refractory material to find phosphatic material, etc. Xinjiang refractory bricks, castable refractory, refractory material, silicious, corundum and alumina-magnesia: High alumina and clay refractory bricks can be divided into

- Q:For refractory, what is critical particle size? Thank you.

- 0

- Q:How many types do refractory bricks have? Where the quality of refractory material is best? What is the model?

- Sinosteel Luoyang (Luoyang Refractory Material Plant in the past): High alumina(mainly blast furnace), Gongyi. There are also a series of high-tech materials (silicon carbide, carborundum, etc.) a major producer of high alumina; silicious: Resistant material for steel, glass furnace, cement kiln); magnesia. Divide from uses and divide from chemical texture; silicious(glass furnace): Xinmi, Hennan Province, Lengshui River, coke oven, etc.). As for the models, Yixing and Changxing in Jiangsu Province: Haicheng, Liaoning Province; silicious, I do not understand your intentions; magnesia (nonferrous, steel refining; magnesia: High alumina brick; Dashiqiao area! Please put it in detail.

- Q:What requirements should refractory materials meet?

- Ladle is an necessary equipment to undertake molten steel and continuous casting. As many kinds of steel needs to be processed in the ladle, including argon blowing tempering, alloy composition fine-tuning, refining dusting and vacuum processing, working conditions of the ladle lining have worsened. Their working conditions are as follows. (1) The temperature of molten steel is higher than mold casting ladle. (2) the molten steel stays longerin the ladle. (3) ladle lining are subjected to volatilization and agitation of molten steel under high temperatures and in vacuum. (4) The impact on the lining when undertaking steel liner when the impact effect. Therefore requirements of the ladle refractories are as follows: (1) It can resist high temperature. Molten steel should be able to withstand high temperatures without melting. (2) It can resist thermal shock and can withstand molten steel without cracking and spalling. (3) It can resist slag erosion. The ladle should be able to withstand the erosion of lining caused by slag and alkalinity changes of slag. (4) it should have sufficiently high temperature mechanical strength to withstand the agitation and scouring of molten steel. (5) lined should have certain swelling property so that lining will be united as a whole under the effect of hyperthermal molten steel.

- Q:How to divide fire rating of decorating materials ?

- Decorating materials shall be divided into four levels according to combustibility. Level A: noninflammability; B1: difficult-flammability; B2: combustibility; B3: inflammability.

- Q:For refractory, why is it necessary to store the first mixing materials for some time under proper moisture and temperature?

- It is mainly to remove gas form chemical reactions in the pug, give full play to plasticity and binding properties of combined, and store unburned?brick whose cememting agent is phosphoric?acid or aluminium?phosphate for some time under proper moisture and temperature. For example, to avoid the formed bricks in the initial stage of drying and firing form cracking due to hydration of calcium oxide. Mixing materials is to store the first mixing materials for some time under proper moisture and temperature in order to improve the evenness and moldability of pud, such as making the distribution of combined clay and water more even. The length of storing chiefly depends on the process requirements and the characteristics of blanks. For the producing pug of high temperature kiln furnitures, the storing time is longer. The function of storing mxing materials varies with different natures of blanks. For honeycomb ceramics, it is to fully digest calcium oxide in blanks. For storing magnesia brick blanks containing much calcium oxide, it should be stored for some time in proper humidity and temperature.

- Q:Which are fire proofing thermal insulation materials?

- aluminum silicate fiber, ceramic fiber, etc,

- Q:Does refractory belong to metallurgical auxiliary materials?

- Refractory includes metallurgical auxiliary materials.

- Q:what is the specs of thermal insulation refractory slab ?

- Fireproof insulation specification is 1220 * 2420 1220 * 2420 * 8 * 9. HPL also known as the fireproof board is scientificly named thermosetting resin impregnated paper laminated wood, the abbreviation of which is HPL.Decorative high-pressure Laminate is fire-resistant building materials for decorative purposes. It is rich in surface color, texture and special logistics performance, widely used in interior decoration, furniture, kitchen cabinets, laboratory table, external walls.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory Grade Calcined Bauxite 85% 0-5mm Sands

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords