Refractory GJM Mullite Insulation Brick B-7

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

mullite insulation brick

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-7

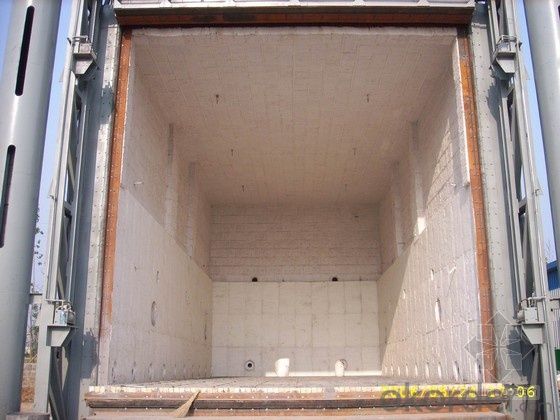

Light weight mullite insulation furnace bricks refractory for sale

Advantage

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-7

Description:

Lightweight mullite kiln bricks refractory for sale are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chomical demands.

Application:Refractory GJM Mullite Insulation Brick B-7

Mullite insulation furnace bricks refractory material can be used in linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etcRefractory GJM Mullite Insulation Brick B-7

Mullite Insulation furnace refractory material can be used as working lining, where contact with flames directly. This kind of brick can save the kiln energy very much

Refractory GJM Mullite Insulation Brick B-7

- Q:Do insulating fire bricks have a high fireproof rating?

- Indeed, insulating fire bricks possess a remarkable fireproof rating. These bricks have been specifically engineered to endure exceedingly high temperatures and offer exceptional insulation against the transfer of heat. They are crafted using specialized refractory materials with limited thermal conductivity, thereby aiding in the retention of heat and preventing its escape from the system. Insulating fire bricks are capable of withstanding temperatures ranging from 2300°F to 3100°F (1260°C to 1700°C), rendering them ideal for utilization in furnaces, kilns, fireplaces, and other applications involving elevated temperatures. Their elevated fireproof rating guarantees their ability to effectively safeguard structures and equipment from the intense heat and flames, enabling secure and efficient operations across diverse industries.

- Q:Are insulating fire bricks resistant to moisture or water damage?

- Yes, insulating fire bricks are resistant to moisture or water damage. They are designed to withstand high temperatures and do not absorb water, making them a suitable choice for applications where moisture or water exposure is a concern.

- Q:Can insulating fire bricks be used as a refractory lining material?

- Insulating fire bricks can indeed serve as a refractory lining material. Their purpose is to effectively insulate against heat transfer by having low thermal conductivity. This quality makes them suitable for applications that necessitate the maintenance or control of high temperatures, such as kilns, furnaces, and industrial ovens. High-temperature environments require refractory lining materials to safeguard their structure against the intense heat generated within. These materials must withstand thermal shocks, chemical reactions, and mechanical stresses that occur during operation. Insulating fire bricks are a prime choice for refractory lining applications due to their exceptional thermal insulation properties and high temperature resistance. In addition to being excellent insulators, insulating fire bricks have the added benefit of low density, making them lightweight and easy to handle and install. This advantage proves useful in applications where weight is a concern or where frequent replacement or repair of refractory linings is necessary. It is important to acknowledge that the specific type and composition of insulating fire bricks may vary, and different applications may require different properties. Therefore, it is vital to consult with a refractory engineer or supplier to guarantee that the chosen insulating fire bricks are appropriate for the specific requirements of the application.

- Q:What is the typical thermal diffusivity of an insulating fire brick?

- The thermal diffusivity of an insulating fire brick can vary depending on its composition and manufacturing process. However, typically, insulating fire bricks have thermal diffusivity values ranging from approximately 0.05 to 0.2 mm²/s. Thermal diffusivity measures the speed at which heat can pass through a material. A low thermal diffusivity suggests that the material is a good insulator, as it does not conduct heat quickly. Insulating fire bricks are designed to have low thermal diffusivity to minimize heat transfer and provide effective insulation in high-temperature applications, like furnaces, kilns, and fireplaces. It is important to note that the specific thermal diffusivity of an insulating fire brick can be influenced by various factors, including the type of raw materials used, the manufacturing process (such as firing temperature and duration), and any additives or coatings applied to enhance insulation properties. Therefore, consulting the manufacturer's specifications or conducting specific tests is crucial to determine the thermal diffusivity of a particular insulating fire brick.

- Q:Can insulating fire bricks be used in kilns or furnaces?

- Yes, insulating fire bricks can be used in kilns or furnaces. These bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for lining kilns and furnaces to enhance energy efficiency and maintain high temperatures.

- Q:Can insulating fire bricks be used in chimneys and fireplaces?

- Yes, insulating fire bricks can be used in chimneys and fireplaces. These bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for use in areas where heat is generated, such as chimneys and fireplaces. They help to prevent heat loss and improve the efficiency of the heating system.

- Q:Can insulating fire bricks be used in chimneys and fireplaces?

- Chimneys and fireplaces can indeed utilize insulating fire bricks. These bricks are specifically crafted to endure high temperatures and offer exceptional insulation. They are constructed from lightweight materials like ceramic fibers or refractory materials, which aid in minimizing heat transfer. Thus, they are an optimal choice for lining chimneys and fireplaces since they retain heat within the firebox and prevent its escape through the chimney. Moreover, insulating fire bricks enhance the heating system's efficiency by reducing heat loss and elevating the overall heat output. However, it is crucial to emphasize that insulating fire bricks should only be employed in appropriate sections of the chimney or fireplace, such as the firebox. Conversely, the smoke chamber or flue necessitate different types of bricks capable of withstanding the corrosive effects of flue gases.

- Q:Can insulating fire bricks be used in chimney construction?

- Yes, insulating fire bricks can be used in chimney construction. These bricks have high heat resistance and low thermal conductivity, making them suitable for lining chimneys and other high-temperature applications. They help to insulate the chimney and prevent excessive heat transfer, reducing the risk of structural damage and improving energy efficiency.

- Q:Can insulating fire bricks be used for flooring insulation?

- Insulating fire bricks excel in high-temperature scenarios like kilns, furnaces, and fireplaces, but they may not be the optimal choice for insulating flooring. Their softer and less durable nature compared to other flooring materials renders them vulnerable to damage caused by foot traffic. Moreover, they may not provide adequate support and stability for the floor, particularly in areas with heavy foot traffic. To insulate flooring, it is generally advised to use materials specifically designed for this purpose, such as foam boards, cork, or rubber underlayments. These materials possess greater resilience and durability, making them better equipped to withstand the demands of flooring applications. They also offer superior noise reduction and moisture resistance, which are crucial factors to consider when insulating flooring.

- Q:Can insulating fire bricks be used in brick ovens?

- Yes, insulating fire bricks can be used in brick ovens. Insulating fire bricks are designed to withstand high temperatures and provide excellent heat insulation, making them ideal for use in brick ovens. These bricks are made from lightweight refractory materials, which help to reduce heat loss and improve the overall energy efficiency of the oven. Additionally, insulating fire bricks are resistant to thermal shock, meaning they can withstand rapid changes in temperature without cracking or breaking. This makes them a reliable and durable choice for brick oven construction.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory GJM Mullite Insulation Brick B-7

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords