Refractory GJM Mullite Insulation Brick B-4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

mullite insulation brick

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-4

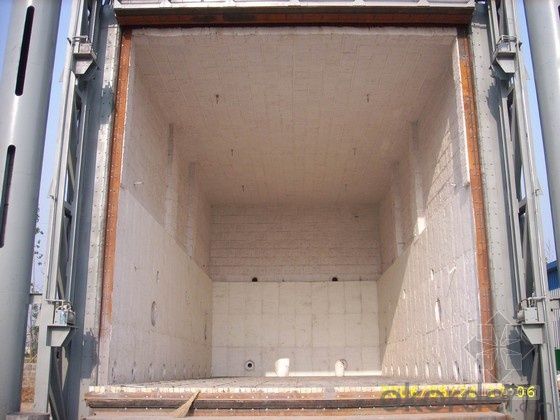

Light weight mullite insulation furnace bricks refractory for sale

Advantage

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-4

Description:

Lightweight mullite kiln bricks refractory for sale are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chomical demands.

Application:

Refractory GJM Mullite Insulation Brick B-4

Mullite insulation furnace bricks refractory material can be used in linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etc

Refractory GJM Mullite Insulation Brick B-4

Mullite Insulation furnace refractory material can be used as working lining, where contact with flames directly. This kind of brick can save the kiln energy very much

Refractory GJM Mullite Insulation Brick B-4

- Q:Are insulating fire bricks suitable for use in steel mills?

- Yes, insulating fire bricks are suitable for use in steel mills. Insulating fire bricks have high temperature resistance and excellent thermal insulation properties, making them ideal for lining furnaces and kilns in steel mills. They help to maintain high temperatures while minimizing heat loss, resulting in energy efficiency and cost savings. Additionally, insulating fire bricks also provide protection against thermal shock and chemical corrosion, enhancing the overall durability and longevity of steel mill equipment.

- Q:Can insulating fire bricks be used in high-temperature insulation panels?

- Indeed, high-temperature insulation panels can incorporate insulating fire bricks. These bricks are specifically engineered to endure elevated temperatures and deliver exceptional thermal insulation. Constructed from lightweight refractory materials boasting low thermal conductivity, they effectively curtail heat transfer. Their versatility extends to applications such as furnaces, kilns, and high-temperature insulation panels. Remarkably, they can withstand temperatures reaching 3000°F (1650°C) while proficiently retaining heat, rendering them an optimal selection for high-temperature insulation panels.

- Q:How do insulating fire bricks affect the overall fire safety of a structure?

- Insulating fire bricks greatly enhance the fire safety of a structure. Due to their high thermal resistance, these bricks effectively prevent the spread of heat, reducing the risk of structural damage and minimizing the chance of fire spreading to adjacent areas. Additionally, their low thermal conductivity helps to retain heat within the furnace or fireplace, improving energy efficiency and reducing the likelihood of accidental fires.

- Q:Can insulating fire bricks be used in reheating furnaces?

- Yes, insulating fire bricks can be used in reheating furnaces. Insulating fire bricks are designed to have excellent thermal insulation properties, which makes them ideal for use in high-temperature applications such as reheating furnaces. These bricks have low thermal conductivity, meaning they can effectively retain and reflect heat, resulting in energy savings and improved heating efficiency. Additionally, insulating fire bricks are lightweight and have good resistance to thermal shock, making them durable and suitable for the rapid temperature changes experienced in reheating furnaces. Overall, insulating fire bricks are a suitable choice for insulating and lining the walls of reheating furnaces, providing efficient heat retention and helping to maintain uniform temperatures throughout the furnace.

- Q:Can insulating fire bricks be used in electric arc furnaces?

- Yes, insulating fire bricks can be used in electric arc furnaces. Insulating fire bricks are made of lightweight materials with high insulating properties, which make them ideal for applications where heat insulation is required. Electric arc furnaces generate high temperatures and require effective insulation to contain the heat within the furnace chamber. Insulating fire bricks can withstand the intense heat produced in electric arc furnaces, preventing heat loss and conserving energy. Additionally, their insulating properties help maintain a stable temperature inside the furnace, ensuring efficient melting and refining of metals or other materials. Therefore, insulating fire bricks are a suitable choice for use in electric arc furnaces.

- Q:Are insulating fire bricks resistant to insect infestation?

- Insulating fire bricks are not specifically designed to be resistant to insect infestation. These bricks are primarily used for their thermal insulation properties in high-temperature applications such as kilns, furnaces, and fireplaces. While they are not typically prone to insect damage, they are not completely immune to it either. Insects may still be able to penetrate the bricks if they find small cracks or openings in the material. However, insulating fire bricks are generally dense and compact, making it difficult for insects to burrow or nest within them. It is always recommended to take preventive measures to control and eliminate potential insect infestations in any construction material, including insulating fire bricks, to ensure their longevity and functionality.

- Q:Is it possible to repair damaged insulating fire bricks?

- Yes, it is possible to repair damaged insulating fire bricks. The damaged bricks can be repaired by using refractory cement or mortar to fill in cracks or gaps. Additionally, damaged portions can be cut out and replaced with new bricks. However, the extent of the damage and the specific repair method required may vary depending on the severity of the damage.

- Q:Can insulating fire bricks be used in chimney liners?

- Yes, insulating fire bricks can be used in chimney liners. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation properties. They are commonly used in applications such as kilns, furnaces, and fireplaces where heat retention is important. When used as chimney liners, insulating fire bricks help to protect the chimney walls from the extreme heat generated by the fire, while also minimizing heat loss. This can improve the efficiency of the chimney and reduce the risk of damage to the surrounding structure. However, it is important to consult with a professional chimney technician or engineer to ensure that the specific type of insulating fire brick being used is suitable for the intended application and meets all relevant safety standards and building codes.

- Q:Are insulating fire bricks resistant to acid attack?

- Yes, insulating fire bricks are generally resistant to acid attack. Insulating fire bricks are made from materials that can withstand high temperatures and are designed to provide excellent insulation properties. These bricks are typically made from lightweight refractory materials such as alumina, silica, and other refractory oxides. These materials are known for their resistance to chemical corrosion, including acids. However, it is important to note that the resistance of insulating fire bricks to acid attack can vary depending on the specific composition and manufacturing process of the bricks. Some bricks may have higher resistance to acids compared to others. Therefore, it is recommended to consult the manufacturer or supplier for specific information on the acid resistance of their insulating fire bricks. In general, insulating fire bricks are commonly used in applications where they may come into contact with acids, such as in industrial furnaces, kilns, and other high-temperature environments. They are known for their durability and ability to withstand harsh chemical environments, including exposure to acids. However, it is always important to consider the specific chemical composition and concentration of the acids involved, as well as the temperature conditions, when determining the suitability of insulating fire bricks for a particular application.

- Q:Can insulating fire bricks be used in the construction of glass melting furnaces?

- Yes, insulating fire bricks can be used in the construction of glass melting furnaces. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in the extreme heat of glass melting processes. Their low thermal conductivity helps to retain heat within the furnace, improving energy efficiency and maintaining a stable melting environment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory GJM Mullite Insulation Brick B-4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords