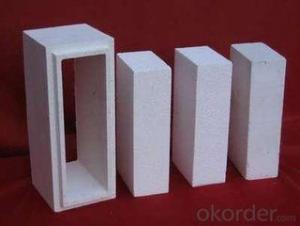

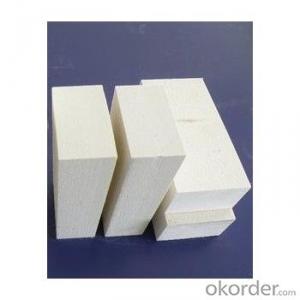

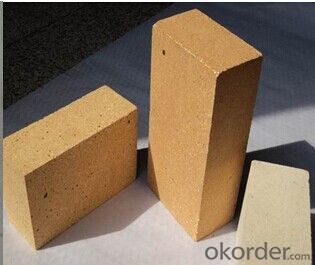

Refractory Fireproof Mullite Insulating Fire Brick Refractory Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Details: | Wood carton box:10pcs/carton wooden pallet:544pcs/pallet |

Delivery Detail: | 15 Days deposit |

Specifications

1. insulating fire brick

2. density: 0.8-1.3g/cm3

3. thermal insulation brick

4. ASTM & JIS standard

DESCRIPTION OF PRODUCTION

CCEFIRE Mullite Insulating Fire Brick is made from high-grade, high purity refractory materials by mixing, press-forming, drying, sintering and

machining. Good process providing excellent heat insulation at high temperature and offers genuine energy savings.It offers a combination of

insulating properties with load bearing ability. CCEFIRE mullite insulating fire brick are suited to applications above 1000°C or 1832°F and

particularly suited to highest temperature applications above 1600°C or 2800°F.

Technical Data

Quality | JM-23 | JM -26 | JM -28 | JM -30 | JM -32 | |

Classification temperature(oC) | 1260 | 1430 | 1540 | 1650 | 1760 | |

Bulk density (g/cm3) | 0.6 | 0.8 | 0.9 | 1 | 1.25 | |

Crushing strength (Mpa) | 1.2 | 1.6 | 2.1 | 2.5 | 3.5 | |

Modulus of rupture (Mpa) | 0.9 | 1.4 | 1.6 | 2.1 | 2.1 | |

Permanent linear change (CT-30oCX24h)% | 0.5 | 0.4 | 0.5 | 0.9 | 0.9 | |

Reversible thermal expansion at 1100oC | 0.5 | 0.7 | 0.8 | 0.9 | 1.1 | |

Thermal shock resistance(cycles)1100oC Water cooling | 30 | 30 | 30 | 30 | 30 | |

Thermal conductivity (W/m.k) | 400oC | 0.14 | 0.27 | 0.32 | 0.41 | 0.49 |

600oC | 0.16 | 0.29 | 0.34 | 0.43 | 0.5 | |

800oC | 0.18 | 0.31 | 0.36 | 0.44 | 0.51 | |

1000oC | 0.2 | 0.33 | 0.38 | 0.45 | 0.53 | |

1200oC | - | 0.35 | 0.41 | 0.47 | 0.56 | |

Chemical Analysis (%) | Al2O3 | 37 | 58 | 67 | 73 | 77 |

Fe2O3 | 0.7 | 0.7 | 0.6 | 0.5 | 0.4 | |

other products

- Q:What is the price of refractory bricks?

- The construction is superior, the light insulating brick has good machinability, and the construction is convenient and simple, and the labor intensity can be reduced, the construction efficiency can be improved, and the construction period can be shortened. The price is determined by the choice of material and volume density, from several hundred to 5000 yuan, mainly with the choice of material

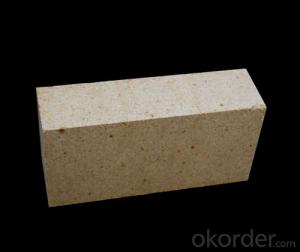

- Q:The introduction of mullite brick

- General alumina content in 65% ~ 75% between. In addition to mullite, the mineral composition contains lower amounts of glass phase and square quartz, and alumina containing a small amount of corundum.

- Q:What is the difference between mullite ceramics and alumina ceramics? Can you tell me something to do with floor tiles?

- Mullite is formed by the reaction of alumina with silica. The main difference between him and alumina is that:Hardness: alumina is harder than mullite, but two are tough enough, and are not easy to break.Corrosion resistance: mullite acid is not alkali resistant. Alpha alumina ceramic acid, alkali resistance - for floor tiles, alumina corrosion resistance is too high, unnecessary.

- Q:The difference between the high aluminum corundum brick and corundum mullite brick

- Tiles are called floor tiles, floor tiles, polished tiles and glazed tiles are glazed tiles, bricks are samples of all kinds of tiles, ceramic tiles will be placed in the tile shop, tiles are also divided into outer wall tiles and inner wall tiles, modern brick and antique brick

- Q:What are the properties of corundum mullite?

- Lightweight materials have uniform internal structure, high compressive strength, corrosion resistance, heat shock resistance, oxidation resistance, high temperature and low thermal conductivity.

- Q:(refractory castable, silicon carbide brick, mullite bricks etc.) do testing should be commissioned by the project? What are the specific qualification standards? Thank you

- Different refractory materials have different requirements, specific industry or national standards, such as LZ can check the mullite bricks GB / standard, there should be a harvest, do testing project is in accordance with the requirements of the LZ need to determine the use requirements

- Q:Jm26 mullite aluminum content in the number, ask God to answer. 23 more. How is this identified with the naked eye?

- Under strong alkaline conditions, aluminum is separated from other metal ions by the amphoteric nature of aluminum.

- Q:Mullite bricks in alumina alumina is what?

- Quality solutionsMullite brick:With mullite as main crystalline phase of high alumina refractory products. Mullite bricks containing Al2O3 64%~75%, refractoriness >1790? C, normal temperature compressive strength 70~260MPa, softening the starting point for 1600~1700 degrees. The manufacturing method for casting and sintering process.

- Q:Mullite brick

- Mainly used for hot blast stove of blast furnace and furnace bottom and furnace, glass furnace regenerator, sintering kiln, petroleum cracking dead lining system.

- Q:Refractory bricks (mullite bricks) can be used on the walls of buildings?

- In many architectural design, high-rise fire rating is placed in the important position of the topic, especially when the floor height is more than 20 layers, we have more stringent requirements for the choice of fire resistant materials. The building wall, kitchen flue, boiler flue, flammable zone must use a firewall barrier, in many refractory refractory brick is the product of choice for fire resistance of refractory brick masonry is more stable.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory Fireproof Mullite Insulating Fire Brick Refractory Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords