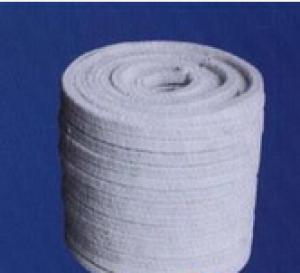

Refractory Ceramic Fiber Rope for Heat Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of ceramic fiber square braided rope

(1) Excellent refractoriness

(2) Excellent chemical stability and thermal stability

(3) Low thermal conductivity, low thermal capacity

(4) Resist to external mechanical forces

(5) Able to withstand any thermal shock

(6) Generate no gaps between modules

Application of ceramic fiber square braided rope

(1) High temperature pipe insulation and sealing

(2) cable insulation coating

(3) coke oven opening sealing

(4) pyrolyzer brick wall expansion joints

(5) electric stove and bake oven’s door sealing, boiler

(6) high temperature gas seals

(7) flexible expansion joint connection;

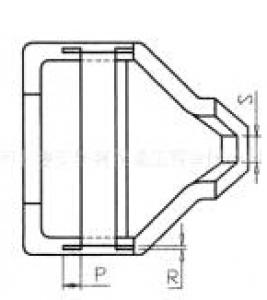

Specifications

Ceramic Fiber Round Rope

1.)Dia.:8MM

2.)Refractoriness:800-1400 degrees

FD-CM102

Ceramic Fiber Round Rope

1)Braided by ceramic fiber yarns,it is used as heat insulating materials and an execllent substitute for asbestos rope.

2)coke furnace,stove and boiler burner,chimney door sealing valve or pump,exchanger

Packaging detairls:

1)carton box

2)delivery time:15-20days after the order confimed

3)supply ability:500meter per day

4)carton box:1600pxx800pxx700px ,

carton package:N.W

Max temperature(℃) | 1260 | |

product name | glass filament reinforced tape | stainless steel frinforced fiber tape |

working temperature(℃) | 650 | 1050 |

water content | ≤ 2% | |

organic content | ≤ 15% | |

density | 500kg/m3 | |

size specification | ||

thickness | 2mm; 3mm | |

width | 20mm; 30mm; 40mm; 50mm; 60mm; 75mm; 80mm; 100mm; 150mm | |

length | 30m | |

- Q:The difference between ceramic fiber cloth and ceramic fiber paper

- 1. appearance. The ceramic fiber cloth has an obvious grid like appearance, and the ceramic fiber paper is very few or even mesh like.2. density. The density of ceramic fiber paper is greater than that of ceramic fiber cloth.3. thickness. Ceramic fiber paper, the thinnest can do 0.5mm, ceramic fiber paper can not do so thin, generally thin, there are also 2mm.4. stand erect. Ceramic fiber paper can be like in our life that can be placed on the A4 paper, mold, stand up. Ceramic fiber cloth is like the fabric used in our 5. lives. It's soft and doesn't stand upright.6. tear resistance. The toughness of the ceramic fiber paper is not as good as that of the ceramic fiber cloth.

- Q:What are the uses of ceramic fiber blankets?

- The ceramic fiber blanket has a strong resistance to wind erosion, and can be directly contacted with flame and high-speed airflow. Because of its excellent fire resistance, high temperature stability, high thermal shock resistance, low heat capacity and high temperature conditions, high compressive strength.

- Q:What are the man-made fibers polluting the environment?

- Fibers are roughly divided into natural fibers, man-made fibers, and synthetic fibers[natural fiber] refers to the natural growth or formation of fiber, including plant fiber (natural cellulose fiber), animal fibers (natural protein fiber) and mineral fiber. Plant fibers include: seed fiber, phloem fiber, leaf fiber, and fruit fiber. Seed fiber is the unicellular fiber that grows from the epidermal cells of some plant seeds. Such as cotton, kapok. Bast fiber is a single fiber or process fiber obtained from the phloem of some plants. Such as: linen, ramie, jute. Leaf fiber is the process fiber obtained from the leaves or sheaths of some plants. Such as: sisal, abaca. Fruit fiber is the fiber obtained from the fruit of some plants. Coconut fiber. An animal fiber (natural protein fiber) that includes hair, fiber, and gland fibers. Hair follicles: fibers of the hair follicles that have multicellular structures and are composed of keratin. Such as: wool, cashmere, camel hair, rabbit hair, Ma Haimao. Silk fibers: fibers formed from the glands of some insects, especially those produced by lepidopteran larvae, and fibers formed by secretions of some mollusks. Such as: silk.

- Q:What are the differences between digital textile printing ink and printing ink?

- 3. acid ink:Suitable for jet printing of silk, wool and nylon;4. coating ink:Suitable for direct printing of all textiles.

- Q:Does the component of textiles contain 70% acrylic? Does it hurt the body?

- Acrylic has high transparency, light transmittance of 92%, a "plastic crystal" reputation. And excellent weather resistance, especially for outdoor, in other plastic crown, and has a good surface hardness and gloss, processing plasticity, can be made into a variety of shapes and products needed. There are a wide variety of boards, rich in color (including translucent swatches), and another feature is that the plate is still able to maintain high transparency.

- Q:What is the function of (ceramic) ceramic powder?

- According to different porcelain stent materials are divided into: metal porcelain powder, pure titanium porcelain powder, casting porcelain powder, two alumina porcelain powder, zirconia porcelain powder, etc.. According to the temperature is divided into: high temperature porcelain powder, medium temperature porcelain powder, low temperature porcelain powder.

- Q:Is aluminum silicate fiber completely insulated from heat transfer?

- Fire-resistant insulation layer is used to make ceramic fiber module insulation, thermal insulation thickness of four hundred mm, the ceramic fiber blanket double extrusion, ceramic fiber module in parallel sorting, the trolley furnace wall temperature to plate temperature rise of forty-five degrees, which is almost a best isolation effect.

- Q:Which is better, ceramic fiber or spray velvet?

- Different applications of two kinds of ceramic fiber cotton:In 1, production of HLGX ceramic fiber module: rejection due to thick and long silk fiber is better than spraying silk carpet, in the block made of the folding process, blowing fiber blankets easily broken and torn, and thrown silk fiber blanket can be folded very closely and not easy to damage, the quality will directly affect the block lining quality;The vertical layer 2, large boiler insulation blanket shop carpet fiber application: rejection due to long and thick, has better tensile resistance, more durable, so the rejection is better than spray carpet carpet;3, application of ceramic fiber textile, silk fiber thick and long and has good spinnability, the ceramic fiber thrown silk became the production of ceramic fiber textiles (cloth, tape, rope, pipe and other special materials);

- Q:Can ceramic fibers be spun?

- The utility model can also achieve higher strength by increasing metal wire reinforcement, and finally can be made into products such as yarn, cloth, belt, rope, packing, etc., and the utility model has wide application.

- Q:What's the temperature of the high temperature ceramic fiber cloth and ceramic drill cloth?

- The ceramic fiber cloth is only one kind of one thousand degree temperature resistance. It is reinforced cloth for steel wire.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory Ceramic Fiber Rope for Heat Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords