Refractory Bulk Fiber Corrosion Resistance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m³

- Supply Capability:

- 68 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Bulk Fiber Corrosion Resistance

Description for Refractory Bulk Fiber

Ceramic fiber module/Refractory Bulk Fiber is made from high quality clay, high

purity alumina and silica oxides by spun or blown process.

Ceramic fiber bulk module/Refractory Bulk Fiber has a range of products:ordinary type,standard form,high-purity type, high-alumina type and containing zirconium type.Different types of products used different materials.The performance of Ceramic fiber module also has difference,and they are suitable for different workong temperatures.

Refractory Bulk Fiber module/Refractory Bulk Fiber can be used after optional cutting .When Ceramic fiber module storage should be paid attention to moistureproof.The high-alumina type and containing zirconium type products can be directly used as furnace lining .And using high-temperature refractory adhesive when stick.

Features for Refractory Bulk Fiber Module

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Advandage for Refractory Bulk Fiber Module

◆High-purity type

◆High-temperature refractory

◆Al Content (%): 32-55

◆Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

◆Density: 64-160kg/m3

◆Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

Images for Refractory Bulk Fiber Module

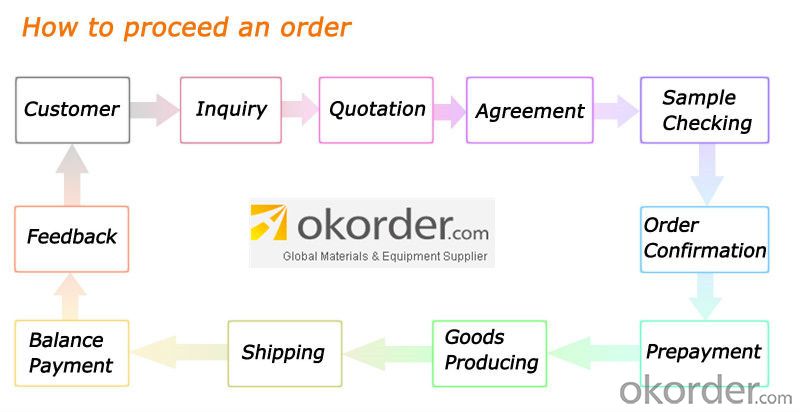

◆Product Process

FAQ

Can we accept OEM for Ceramic fiber module?

YES! We can according your demand to produce.

Can we accept the detective of the third-party verification company ?

YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

If you have any enquiry,please don't hesitate to contact us, okorder will provide our best products and services for you!!

- Q:eat healthy what can i do

- thye are not good to eat, id advise you not to.

- Q:Can someone please help me out with some info? I have changed my diet and completely cut out any junkfood, I have cut out almost all carbs, I am just eating lots of veggies, some dairy, and a lot of proteinUnfortunately I have become constipated which is shocking considering how much more fiber I am getting via all the veggiesI used to be very regular when I was eating poorlyI was getting fatter by the day but I went to the bathroom without any problemsI am drinking lots of water, working out, but I just can't go to the bathroom properly!Is this normal and when can I expect it to stop? I have been on this plan going into my 4th week and I have been REALLY strict about my diet for 2 weeksHelp meh!

- Our bodies need a complete diet of whole foods from all the food groups to function properlyThis is one of the problems with fad dietsComplex carbohydrates are essential for energy and overall healthThe reason carbs get such a bad rap is because the modern diet is loaded with simple carbs (sugars)A high protein diet without enough fiber and complex carbs often leads to constipationWe need to provide the body with both insoluble and soluble fiber to add bulk to the stool and give the intestines something to push against during digestionPlus adding complex carbs to the diet extends the absorption rate of the proteinsTry adding some beans to your dietComplex carbs, protein, and ironJust about the best all around food there isAnd the lowly small red bean is the highest antioxidant food aroundIt just isn't sexy so we get all these exotic antioxidant supplements that sellAnd yes the gas will start until the lower intestines build the beneficial bacteria populations needed to breakdown the added fiberTry adding a half a cup a day for a few weeks and then increase to a cup or moreThrow in some barley for some serious fiberAsk yourself this question - Is this the diet I am going to follow for the rest of my life? Focus on a life diet of whole fresh foods from all the food groups for long term success.

- Q:I have a full time job, and as many people out there, I am struggling to make ends meetWhat are some things I could do to earn some extra cash?

- The supreme court is only allowed to rule on Constitutional issuesEverything else is left up to the states - ergo the votersIf it has no direct Constitutional bearing that is the way that it is supposed to beThe Constitution protects against taking life, liberty, or property w/out due processBecause there is no mention of homosexuality in the Constitution, it is a states rights issueMarriage is constitutionally listed as a states rights issueGay marriage must therefore be left up to the statesThat's where it gets trickyThe Constitution says that a marriage in one state is valid in anotherSo, if Mass allows gay marriage and KS doesn't-KS would have to honor a gay marriage if the couple moved from Mass to KS.

- Q:So I am in the process of buying a homeI came across an abondoned home, bank owned that has been empty for about 2 yearsThe problem is that the roof had been leaking and damaged all the ceilings, there's mold growing onMy question is, since the water probably got behind the walls would changing the walls for the whole house be good enough? Or is there more to it.

- I'm sorry to say I don't think it is of a very high quality to get all full of pils of lint unless you washed it with towels or something else fuzzyI don't think you can get rid of itTry a nice microfiber fleece blanket and always wash them separate from anything else.

- Q:Which rollers give more volume? Self Hold, Ceramic Thermal, Ball, Foam or Bendy?

- i'm interior the comparable boat! I even have thinner hair and no remember what I do it refuses to hold any curlI ve tried each product decrease than the sunlight- protecting sprays that experience extra like glue, warm rollers, braiding it whilst it s moist and then slumbering in them, slumbering in foam rollers, hairspray that makes my hair immovable, curling with my straightener, curling with costly curling irons, layering, perms, etcMy closet looks like a elegance grant keepi will permit you understand now that perms will in common terms serve to make your hair kinky and frizzy so save your self the unhappinessAnd as somebody reported already, it is going to in common terms fall outas quickly as I straighten my hair, it gets quite stringy and that i m continuously brushing it on the endsOn suitable of that I even have an oily scalp so I m continuously having to reapply dry shampooI even have made a number of hairdressers throw up their arms in frustration and shake their heads as to why my hair is so uncooperativeregrettably, there s only not something you're able to doYour caught with the hair you havei will say that I even have embraced braids, up-do s, and clip-in extensions (the real ones might reason you to unfastened your hair completely so i don't propose them in any respect- some hair is extra proper than none!)I only had to settle for that i became never going to have the magnificent waves and curls that I see on different womenSo sorry yet understand you aren t on my own :/

- Q:I'm not looking for a quot;magic pillquot; or snake oilI work out pretty wellAt least a half-hour of cardio and good amount of reps (and variety) of weight lifting and resistance workouts about 3-4 times a week.I also eat relatively rightAside from the occasional hot dog and/or BBQ type food, I stay away from fast food; eat a lot of green vegetables and trying to put more fiber in there; usually just have a protein shake for breakfast; and I don't even like sweets of any kind.so, I cut those outI currently weigh about 165 and I'm 5'8''I'm not a fitness enthusiast, so I don't know a lot on this topicAgainI'm not looking for something to do the work for meI just don't know what to trust and everything I see promises to quot;transform youquot; or somethingI just want to loose 12 pounds, hereI lost about 9 pounds a couple months back but pretty much hit a wall after thatIs 12 pounds more a little unrealistic? Anyone ever went through this similar situation?

- It's made for use with a blow dryerIt just means that it spreads the heat around and that the ceramic and ions are supposed to smooth your hair.

- Q:just a question that i have been wondering about.Does anyone have a real reason and what part it plays in our life?also what wouldnt we be able to do in life if we didnt have it?

- It should be insulated corddespite the fact that the cord used is in many cases aluminum or for greater performance copper cord with a coating of varnish (or another guy made coating) that acts as insulationthis enables a compact wiring with effective coupling to the magnetic container.

- Q:Which thermal paste is better and why?

- When you just wash your hair put moose in it (product to keep hair moist and not so fizzy) and if you have sponge rods that worksSleep with it overnightOr get Hot N Gold curling iron with the spirals going around it they should be 40 bucks or a conair curlerGood luck ????

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory Bulk Fiber Corrosion Resistance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m³

- Supply Capability:

- 68 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords