Refractory Brick for Blast Furnace High Refractoriness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refractory Brick for Blast Furnace High Refractoriness

Brief discription for Refractory Brick for Blast Furnace

CMAX high alumina refractory bricks are classified according to alumina content ranging from 48% to 90%.

CMAX refractory brick are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln,regenerator, etc.

Brief features for Refractory Brick for Blast Furnace

◆Low thermal conductivity

◆Excellent acid and base slagging resistance

◆High refractoriness

◆Excellent thermal shock resistance

◆Excellent mechanical strength

◆Good spalling resistance and wear resistance.

◆Good corrosion resistance.

◆High-temperature creep rate is quite low.

◆Good volume stability at high temperature.

◆Low bulk density, low thermal conductivity, good thermal insulation performance.

Technical data for Refractory Brick for Blast Furnace

ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 | UAL85 | ALP80 |

Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 | 1810 | 1810 |

Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 | 20 | 18 |

C.C.S, Mpa | 39 | 44 | 49 | 53 | 55 | 60 | 100 |

Refractories Under Load (0.2Mpa),℃ | 1420 | 1470 | 1500 | 1520 | 1500 | 1520 | 1550 |

Reheating Linear Change,% | 1450℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 |

Al2O3 Content , % | 48 | 55 | 65 | 75 | 80 | 85 | 82 |

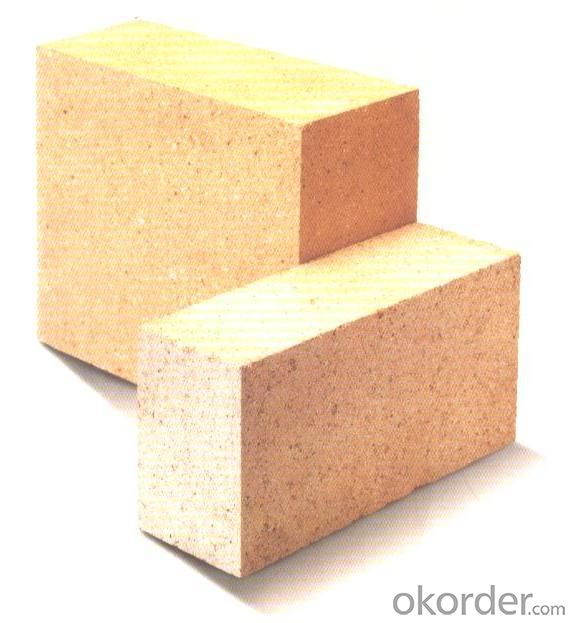

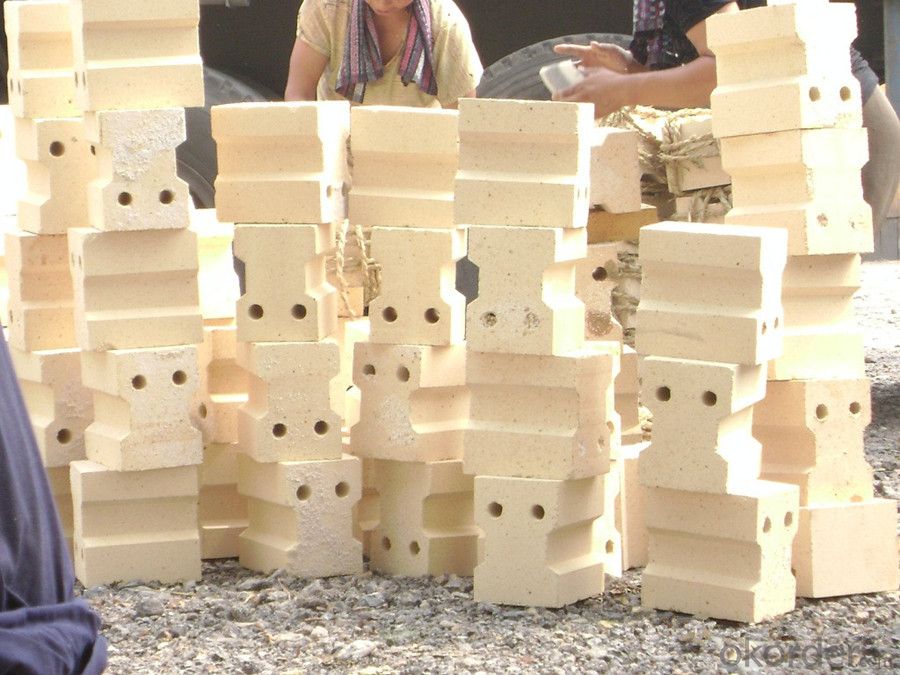

Images/photographs for Refractory Brick for Blast Furnace

◆ breif images-different shape for different usage

◆ Packaging for Refractory Brick for Blast Furnace

◆ Producing Equipment for Refractory Brick for Blast Furnace

◆ Testing Mashines for Refractory Brick for Blast Furnace

WHO WE ARE?

CNBM International (China National Building Materials Group Corporation) 500 Fortune Company.

we are the main supplier for

ALLIED MINERAL PRODUCTS, INC

REFRACTORIES INCORPORATED

SRS SORG REFRACTORY SYSTEMS GMBH,

SUNWARD REFRACTORIES CO., LTD

LILAMA69-1 JOINT STOCK COMPANY etc.

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us,we will provide our best products and services for you!!

- Q:What are the specifications for bricks?

- Ordinary brick size of 240 mm * 115 mm * 53 mm, according to compressive strength (Newton / square millimeter, N / mm2) size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these intensity levels. Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks.

- Q:What's the weight of the refractory bricks?

- Fireclay refractory bricks: 3.4kg-3.8kg - according to the quality of raw materials, prices ranging from 1 yuan to 2.7 yuan, high alumina refractory brick: three, high aluminum in 3.9kg or so. Ordinary T-3 firebrick weight calculation method: 230*114*65*2.2/2.1.

- Q:What is the density of a super high alumina brick and what is the price?

- Super high alumina brick, alumina content of 80% bricks, bulk density of 2.7g/cm3 or more, the factory price of about 1900 yuan

- Q:The difference between ordinary and diatomite brick refractory brick

- To say the difference, the material is the biggest difference. There are diatomite brick density, compressive strength of small brick kiln belongs to the outer thermal insulation, and heavy refractory brick kilns for multi village in direct contact with the flame, high temperature resistance, good compressive strength, but no insulation. Hope to help you.

- Q:Use of high alumina refractory bricks?

- High alumina brick refractory than clay refractory bricks and brick refractory degree are higher, up to 1750~1790 DEG C, which belongs to high-grade refractory materials.

- Q:What are the lining structures of lime rotary kilns and what are the requirements for refractories?

- The current configuration of domestic calcining active lime rotary kiln refractories are as follows: the discharge end of low cement high alumina castable with 3% steel fiber; the cooling zone and the firing zone: dry magnesia spinel brick with high aluminum brick with high temperature; preheating: high alumina brick; low temperature preheating zone: clay brick light clay brick; feeding end: low cement high alumina castable with 3% steel fiber; in addition, brick size also have the corresponding requirements; dimensional tolerances: dimensional tolerances used in different parts of the requirements are not the same, the general control in 2mm; corner damage: general permit edge damage 40mm and 5mm deep within angle loss in the hot and cold surface is allowed to have only one, three edges and the length of not more than 50mm; there are cracks parallel to the use of surface crack is not allowed, cracks of brick surface are allowed.

- Q:The difference between clay bricks and clay bricks

- Clay brick is a small building with artificial bulk. Also called sintered brick. Solid clay brick is one of the oldest building materials in the world. It is a building material that is loved by the people.

- Q:Is glass wool inorganic thermal insulation material?

- Yes, glass wool belongs to one kind of glass fiber. It is a kind of man-made inorganic fiber. Therefore, in the field of thermal insulation materials classified as inorganic insulation materials.

- Q:Introduction of high alumina brick

- Made from alumina or other raw materials of high alumina content; formed and calcined. High thermal stability, fire resistance above 1770. Slag resistance is good, used for masonry steel smelting furnace, glass furnace, cement rotary furnace lining.

- Q:What should be used as binder for making high alumina bricks?

- Bond for making high alumina brick: soft clay has good plasticity, so the high alumina brick is usually made of soft clay as bond. However, the free Al2O3 free SiO2 and bauxite clinker clay in under 1200 degrees occurred two times of Mullization reaction, generate large volume expansion, silicon porosity, strength reduction. Therefore, the amount of clay powder in the ingredient should be no more than 5%.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory Brick for Blast Furnace High Refractoriness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords