Refractory 90 Percent MgO Dead Burnt Magnesite Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

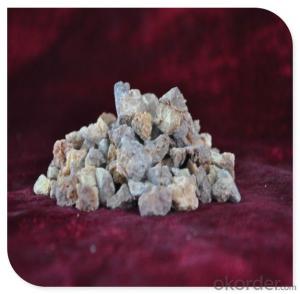

Refractory 90percent MgO Dead Burnt Magnesite Price

Dead Burned Magnesite

Description

Dead Burnt Magnesite is produced in the Rotary Kiln by sintering raw magnesite at a controlled temperature of 1750 degree centigrade and its chemically inactive. Dead Burnt Magnesite is consume almost exclusively in the production of Refractory Field.

Dead Burnt Magnesia Application:

1. Refractory Industry for manufacture of Basic Refractory Bricks .

2. Manufacture of Ramming Mass composition, Fettling material and Magnesite Mortar.

3. It is used in SLAG beneficialness and in SLAG splashing in Arc Furnaces.

4. It is also used as a coating material in Steel Industry.

MgO ≥ | CaO ≤ | SiO2 ≤ | L.O.I. ≤ | BD ≥ g/cm3 | size mm | |

VT-MGO-DBM 87 | 87 | 2.2 | 7.0 | 0.5 | 3.1 | according to the requirement of customer |

VT-MGO-DBM 90 | 90 | 2.2 | 5.0 | 0.3 | 3.15 | |

VT-MGO-DBM 91 | 91 | 2.0 | 4.5 | 0.3 | 3.18 | |

VT-MGO-DBM 92 | 92 | 1.8 | 4.0 | 0.3 | 3.18 | |

VT-MGO-DBM 93 | 93 | 1.6 | 3.5 | 0.3 | 3.18 |

Our Lab

Our service

Large production capacity(20000-tons per month) ensure the fast production cycle after confirmed the order.

Produce the products according to clients' requirements.

Professional Packing,Avoid damage;Competitive Price,Make the products competitive in your market.

Provide 24 hours'consultation service.We are ready to answer our consultations at any time.

- Q:Who know what kind of fire shutter fire rating are there?

- There is no national standard for fire protection performance of fire roller shutter in China, and now the executive standard of GB14102-2005 "fire shutter": F1, fire-resistant time 1.50h; F2, fire-resistant time 2.00h; F3, fire-resistant time 3.00h; F4, fire-resistant time was 4.00h before the national standards of fire shutter grading is introduced, expert advice that fire resistance test be made according to national standard, to reach back fire surface temperature rise requirements, if the refractory limit is greater than or equal to 3.0h, it is said to be super fire shutter, if test not inspect unexposed surface temperature rise as a judgement of the conditions, the door is referred to as ordinary fire shutter doors. I hope my answer can help you

- Q:Does the aluminum silicate thermal insulation material fireproof?

- With stable performance,long fiber length, strong tensile strength, strong seismic performance, low shot, light unit weight, low thermal conductivity, good insulation properties. it is not bad.

- Q:What can red stone refractory do?

- Classification is divided into ordinary and special refractories two major categories. Ordinary refractories are divided into acidic, refractory, neutral and alkaline according to their chemical characteristics. According to the special refractory material consists of high temperature oxide, refractory compounds and high-temperature composite materials in addition, in accordance with the fire intensity can be divided into ordinary refractory products (1580 to 1770 DEG C), advanced refractory products (1770 to 2000 DEG C) and special refractory products (more than 2000 DEG C). According to the product shape can be divided into block (standard brick, special-shaped brick), special shape (crucible, sagger, pipes, etc.) (fibrous silicate aluminum, zirconium oxide and boron carbide material) and indefinite shape (refractory clay, pouring material and ramming material etc.). According to the sintering process, the products are divided into sintered products, casting products and fused blowing products. The main varieties of in general and special refractory materials, common varieties are mainly the following: acid refractories have a larger amount of silica brick and clay. Brick is siliceous products containing more than 93% SiO2, the use of raw materials with silica, silica and other waste. The silica acid slag erosion ability is strong, but vulnerable to the erosion of basic slag, its softening temperature is very high, close to the fire, the volume does not shrink after repeated burning, or even a slight swelling, but poor thermal shock resistance. The brick is mainly used for thermal equipment of glass furnace, coke oven, acid furnace etc.. Containing 30% ~ 46% alumina clay brick, with refractory clay as the main raw material, refractory 1580 degrees to 1770 degrees, good thermal shock resistance, which belongs to the weak acid refractory material, resistance to acid slag, widely used, is the largest production of a kind of refractory material.

- Q:Does anyone know about the A-level fireproof materials?

- rock wool external wall composite board, A1-level fire rock wool board, hidden slit rock wool board ? 30, A1-level fireproof mineral wool sound-absorbing board. What about the sound-absorbing sheet? glass fiber acoustic board engineering of the TV backdrop ? 85, A1-level fireproofing and thermal insulation rock wool board is hydrophobic thermal insulation, external wall thermal insulation materials ? 200, high temperature resistant calcium silicate board, LCFC/calcium?silicate?board is A1-level fireproof materials with high-quality and low-price ? 75, the prices above are from the internet for reference only, and the purchase prices vary according to the market.

- Q:Who knows how to divide the building fire grade and fire resistance grade?

- I hope to help you building fireproof rank division is one of the most basic measure in building fire safety technical measures, Building's fireproof rank is divided into class one, two, three, four according to China's architectural design specification. Fire-resistant capability of the highest level is the strongest; Fire resistance of four level of the weakest. The fire resistance level of a building depends on the combustion performance and fire resistance of the building components that comprise the building. The so-called building component refers to a series of basic components, such as wall, foundation, beam, column, floor, stair, ceiling and so on.

- Q:What are the commonly used fire protection materials

- Firewall. The fire wall is made of non combustible material, and is directly installed on the base of the building or the reinforced concrete frame or fire proof walls . Fireproof limit of the firewall, according to the current "building regulations", is 4 hours, wheras the specification of Technical specification for concrete structures of tall building is 3 hours. doors resistant to fire, heat in a certain period of time These door usually prevent the spread of fire and gas in the fire resistant wall, staircase, pipe well. Fire door can be divided into steel fire doors, wood fire doors and composite materials fire door according to the material used. According to the limit of fire resistance can be divided into the class A fire door (1.2h), B fire doors (0.9), class C fire door (0.6h); (3) fire window. Windows resistant to fire, heat in a certain period of time It is usually installed in the fire resistance wall or doors; the fire shutter. This roller shutter can be refractory in a certain period of time. It is typically used for heat and fire insulation in escalator with difficulties to install fire resistant wall, fire resistant valve and smoke resistant valve. Fire resistant valve is installed in the ventilation and air conditioning system of air supply and return air duct, usually in the open state, fire, It will be turn off when the pipeline gas temperature reached 70 degrees, can meet the requirement for fire resistance and insulation for gas and fire. Smoke fire resistant damper installed in the exhaust system pipe, when the pipeline gas temperature reached 280 degrees, it will close automatically, insulating fire and gas.

- Q:Can quantitative feeder be used in refractory plant? Thank you

- Yes, but the material must be no longer using a simple Q235 material

- Q:Does anyone know what kind of light fireproof materials are there?

- 二, 1, Gypsum plaster board With the building plaster as main raw material, gypsum plaster board is a kind of processed plate made by a special board for protective with an addition of additives and fibers as board core. Gypsum plaster board is characterized by light weight, sound insulation, heat insulation, strong processing performance and simple construction method. 2, Gypsum block Gypsum block is a kind of lightweight building gypsum product which is mainly made of building gypsum, and by adding water, stirring, casting and drying. During the process, , the fiber reinforced materials or light aggregates are allowed in, and the foaming agent can also be added. It has many advantages, such as sound insulation and fire prevention, convenient construction and so on. It is a kind of new and healthy wall material which produces low carbon, enhances environmental protection, and caters to the the times. 3, Fly ash brick is a new type of wall material, and bulk density is one of the main technical indexes. The weight of bulk density can be controlled according to the need of construction and adjustment of technical formula. The dry bulk density of the fly ash brick is about 1540 to 1640 kg / m 3, slightly lighter than the clay brick (1601800 kg /m 3). The flexural and compressive strength of fly ash brick is mainly determined by the production process, the formula and the hydrothermal synthesis reaction mode as well as the need of construction. According to the standards of architectural material industry (JC239 - 2001) released by People's Republic of China, the average value of the flexural strength is 2.5 ~ 6.2Mpa, compressive strength is between 10 ~ 30Mpa. I hope this will be helpful to you

- Q:The effect of a high content of water in liquid resin exerted on refractory material?

- For one thing, Substandard whiteness, transportation, low quality and the storage of refractory material may account for this. For another, a high content of moisture reduced the performance of refractory material. A high content of moisture is equal to buy water with same money in terms of trade settlement. Based on this, we can’t consider the super-standard water content from a single aspect, because the water content in refractory material is definitely super-standard, and another problem is particle size. Many people hold the idea that excessive amount of water content may revive its original performance, but it tends to have influenced the quality of refractory material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory 90 Percent MgO Dead Burnt Magnesite Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords