Recycled Plastic Decking Made in China with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

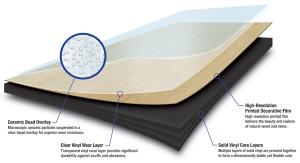

Structure of Recycled Plastic Decking

Item | Recycled Plastic Decking- China 10 Years Experience Composite Decking Suppliers |

Material | Wood Plastic Composite |

Color | Cedar, Coffee, Brown, Black, Dark gray, Light gray, Red wood, Red pine, Yellow, or adjusted to customer's requirement |

Surface | Groove, Wood Grain, Sanding |

Length | 2.2m/pc, 2.9m/pc, 5.4m/pc |

Application | Terrace, Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground |

Packing | PE Film + WPC Pallet (length of 0-2.2m) or Wood Pallet (length>2.2m) optional |

Certificate: | CE, SGS, CMTL |

Main Features of Recycled Plastic Decking

1) 30% Grade A Recycled HDPE

2) 60% Professionally treated dry wood fiber

3) 10% Import Chemical additives (Anti-UV agent, Anti-oxidation agent, stabilizer,ect. )

New material capped outside

What is co-extrusion high solid co-extrusion wpc portable outdoor flooring ?

Co-extrusion is a new BPC manufacturing technology,which comes from the U.S.A.

1.The shell is made of a modified plastic which is anti-scratches and easy to clean as well as keeps the inside BPC material from water absorption.

2.Thickness of the shell:05mm min.

3.The core is still made of bamboo plastic composites.

Picture show of Recycled Plastic Decking

Specification of Recycled Plastic Decking

Name | Recycled Plastic Decking |

Size | W*H=145*30 mm, can be customized |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

FAQ of Recycled Plastic Decking

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q:How to clean plastic suspended floor

- For example, plastic floor, plastic, plastic basketball court and plastic runway. Plastic floor itself has a long service life

- Q:Plastic floor shop no artificial labor costs per square meter

- Buy plastic floor is a choice of material, how to install the plastic floor, plastic floor price, how much money Shanghai plastic flooring, plastic flooring, plastic flooring manufacturers, professional plastic floor, Fuzhou plastic floor, plastic floor thickness, plastic floor green yet,

- Q:How to eliminate the smell of plastic floor

- In the production of plastic floor, the addition of appropriate amount of plastic additives in addition to taste, through the appropriate chemical reaction and Ao, can effectively remove the smell of plastic flooring

- Q:What is the difference between plastic floor and floor leather? What is the wear resistance of plastic floor? How to distinguish the quality of plastic flooring?

- Floor leather is also a plastic floor, also called soft floor, are made of PVC resin as the main raw material, adding appropriate additives in sheet flooring coating or substrate sheet continuous rolling process.

- Q:Performance requirements for plastic flooring

- Comfortable. Plastic floor is required to maintain a good elastic recovery under long-term load or fatigue load. The ground is elastic, soft and comfortable to walk.

- Q:Warm the house, with plastic floor?

- Warm the house, with plastic floor?Sky0384 | browse 928Posted on 2014-08-14 16:34 best answerNo problem with heating, the premise is to buy a good quality brand plastic floor. Such as the LG floor, my home for two years, I feel good, than the wooden floor, like when dealers, abrasion resistance, stain resistance, anti slip, sound insulation, heat conduction, fast walking, feel comfortable, beautiful color texture mosaic diversity without fracture, dimensional stability and construction of heat and moisture are not deformation, environmental protection I think all the advantages of formaldehyde free experience. There are five people in my family, there are elderly people have children, with the ground heating.

- Q:My landlord in the balcony painted a thick paint, more than two months later, the smell is still very large, in order to health, and the landlord to negotiate, they agreed to remove the paint layer, but to keep the corner part. Now two days to remove the paint layer, but the smell is bigger. Now I want to purchase the floor, then at the boundary with plastic tape sticking. Do not know whether it can isolate formaldehyde, etc....

- Can not be separated, if you do so will only slow down the rate of evaporation of formaldehyde. Formaldehyde according to the presence of the environment and other external conditions of the most volatile up to 20 years, the fastest also get 3-5 years.But there is a good way to remove formaldehyde.You can buy dried flowers made photocatalyst. Or ask them to give you a home brush paint, but the price is very high.

- Q:The advantages of plastic floor tile

- Plastic floor is another name for PVC flooring. The main component of PVC material, PVC floor can be made into two kinds, one is homogeneous, is from the bottom to the pattern material is the same. There is a composite type, is the top layer is a pure PVC transparent layer, the following with the printing layer and foam layer. "Plastic floor" refers to the use of polyvinyl chloride materials production floor. PVC floor is widely used in all aspects of home and business because of its rich color and variety of colors.

- Q:Ijiali will be on the floor of the kind of plastic that is connected to a piece of letters, animal patterns, such as the name of what ah

- The ground cushion treasure is a new type of light plate which is extruded by polystyrene resin and other additives. The utility model has a continuous uniform and dense surface layer and a closed cell structure, and the wall of the honeycomb structure has the same thickness.

- Q:Plastic film on the floor for a long time with what method is easier to remove

- No matter what the film is on the ceramic tile and it is not the same material. I would like to use the principle of thermal expansion and contraction of the porcelain and film separation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Recycled Plastic Decking Made in China with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords