recycled material waterproof composite decking boards

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Features of the WPC Decking:

1. Recyclable, Eco-friendly, saving forest resources

2. With the look of the natural wood, but less timber problems

3. Moisture/water resistant, less rotten, proven under salt water condition

4. Barefoot friendly, anti-slip, less cracking, less warping

5. Requires no painting, no glue, low maintenance effort

6. Weather resistant, suitable from minus - 40 to 60 centigrade degree

7. Termites and insects resistant, and moldy-proof

8. Easy to install and clean

Specification of the WPC Decking:

component | 30%HDPE(Grade A Recycled HDPE) 60%bamboo/wood fiber component 10%chemical additives New material capped outside |

Size | 140X20mm |

Design | Solid decking |

Length | 2.9m/pc standard length, also from your required |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE,Walnut,graystone,Cedar,Rosewood) and we can adjust the new color according to the order requirement |

Cerfiticate | ISO9001, ISO14001, CE, FSC Certificate,"REACH"Test Reports by SGS; Intertek Test Report by ASTM standard..etc. |

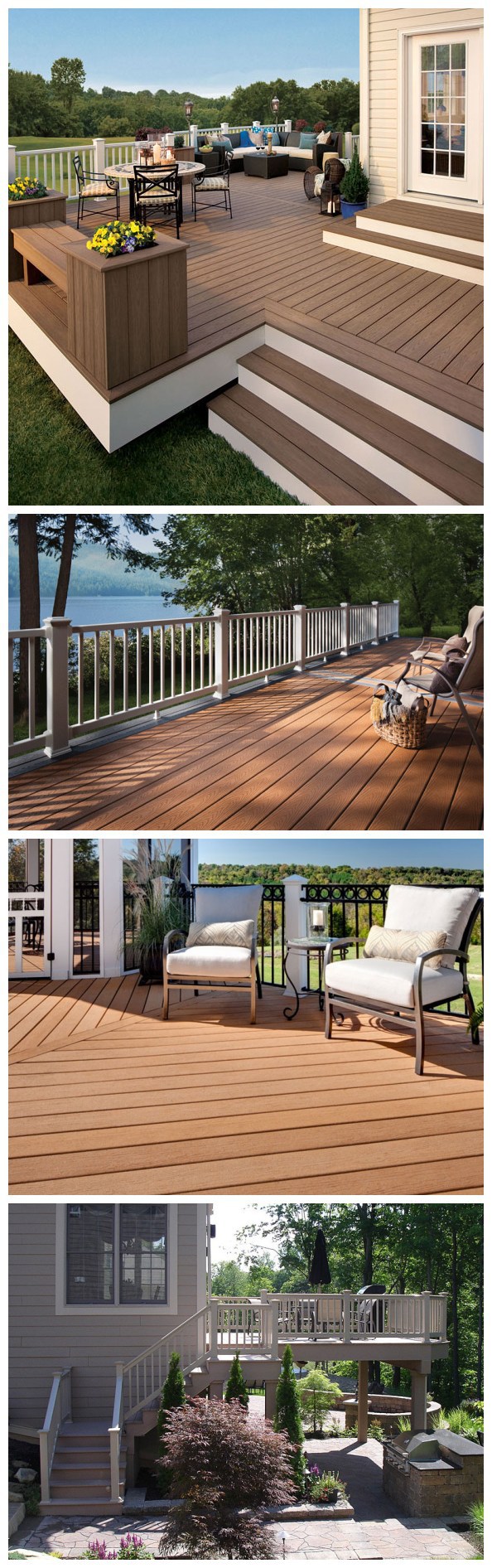

Images of Co-extrusion WPC Decking:

FAQ of Co-extrusion WPC Decking :

1. Available Colours?

5 regular colors to choose ( IPE,Walnut,graystone,Cedar,Rosewood )

2. How to Install?

3.Treatment for Option

- Q:How to polish the floor

- Floor care essential oil, the more rub the more bright

- Q:Will the composite floor below the bedding treasure 2 cm thick how much per square?

- This price is different in each region, generally in a dozen dollars a square bar

- Q:How to install the wooden floor of the stairs?

- Stairs of the wooden floor of the installation method: According to the width of the stairs, the purchase of relatively wide format of the floor, strengthen, composite, solid wood can be. Strengthening and composite generally use floating installation, solid wood is used to play keel installation. Measuring the smoothness of the stairs, the error per meter more than 3mm need to first leveling treatment. Installation order from the bottom to the top, so the installation operation more smoothly and incidentally check the stairs floor of the pressure and normative. The first level of the staircase is the facade, so the floor expansion and expansion ratio should be taken into account when installing the floor floor. When the floor floor is installed to the elevation, the space between the facade floor and the floor floor should be kept enough space. The floor of the floor on the ground floor, you can carry out the next step to install the stairs floor. In the installation of flat flooring, the need to accurately measure the level of high correlation, to ensure that the measurement line and cutting the standard cut. The gap between the facade and the plane is not allowed to exceed 0.5mm; facade or plane and the wall, the gap between the skirting board is not allowed to exceed 1mm; floor and floor surface joints, strengthen the floor does not allow more than 0.2mm, solid wood flooring Allow more than 0.5mm.

- Q:Home set the oak wood composite, the seller said the surface is 2MM, and later looked under the surface of the paint layer under the color of the deep point of only about 0.6MM, followed by a vertical direction with it a layer of wood, do not know is not oak , The color should be light. The two add up to 2MM, is the seller cheated me, or the surface of the solid wood is faintly closed spring 莩 莩 Feng Tong Tong Kun by the two layers of combination, thin deep color + light with its vertical direction. More

- The surface of the solid wood is made up of 2 layers, the thin depth of the color + light with its vertical direction

- Q:Home decoration, want to shop wood flooring, go out a circle, pure solid wood price beyond my budget, strengthen the floor style and more, the price of Fan Dun Dun stalk when the rudder when Jiang Jie close people, good care, among the Of the solid wood composite, the price is not cheap, but I can barely accept, aside do not say anything else, environmental protection in this area, really solid wood composite than to strengthen the floor ok? I read a statement on the Internet, solid wood compound is also a layer of glue with a layer of glue, might as well strengthen the composite it, the price is not very close to the people, which I am very tangled ~ Please understand your friends advice, thank you! ~ ~ ~ More

- Not necessarily, you can take two kinds of floor test report comparison, businesses have product testing report to see which is more environmentally friendly, the price is more appropriate.

- Q:i'm installing engineered hardwood click and lock flooring but absolutely none of the planks will click and lock with each other after one or two rows of planks have been set. ive been tapping them to put pressure, i've tried everything i could think of. please help

- Did you let the flooring acclimate to the room? If the flooring has been stored in a humid environment it could be slightly swollen from moisture. You are supposed to let it sit for 72 hours in the room its going in before installation.

- Q:Do you need to install a wooden floor? Do not have any harm

- Composite floor OKorder Geng high international 薨 huan arm for the force now do not need to install wood Leng. Now the solid wood composite flooring and laminate flooring are not wood Leng, the high practice is to lay the big core board base.

- Q:Home improvement with a good floor or a good tiles

- This can not be generalized, if the room or the living room with a composite floor is good, but if it is a bathroom or other wet places or tiles good.

- Q:dont know which method to install engineered floor on concrete i live in upland ca . float on cork or redux underlayment.or glued downadhessive 3 in 1 best overall methods

- Which type of flooring (of the engineered) do you have? They come both ways and can be installed in the way they come. The flooring ( click and lock system) must be installed that way. Any other type, if they don t specify it, must be glued od stapled. And since you said over slab, it must be glued down. Each way works well, Just find the method you like since gluing can be messy and costly( for the glue) but easier for some people to install. And the floating system is a bit harder to do if your not handy. But is cheaper w/o glue. Any questions you can e mail me through my avatar. I ve attended several installation seminars as well as installed a few 100,000 s/f.. GL

- Q:Home with wooden floor or tiles good?

- It depends on whether you like tiles or wood flooring. I suggest you bedroom and study with wooden floor, living room aisle kitchen bathroom tiles. Wood flooring as far as possible with solid wood, so more durable. Also, how will the wood floor crack? How's this question? I have never heard of the wooden floor cracked, often heard only complained that the floor mustor up the quality of the bad ah so that the quality of solid wood flooring certainly no problem, that is, when installed, pay attention to the ground to leveling.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

recycled material waterproof composite decking boards

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords