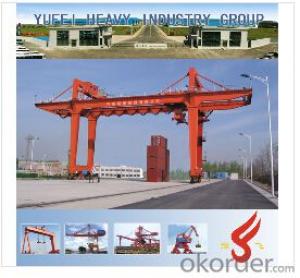

Rail Mounted Container Gantry Crane

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rail Mounted Gantry Crane

Quick details

Feature: Gantry Crane

Rated Loading Capacity: 10-100T

Max. Lifting Height:No limited

Brand Name: KUANGYUAN

Warranty: One year

GB/T 19001-2000 idt ISO 9001:2000:Passed

Weight overload protection function:Included

Buffer:Polyurethane materials

______________________________________________

Condition:New

Rated Lifting Moment:Different

Span:

18~35m (it can de redesigned) as client's requirements)

Model Number:U Model

After-sales Service Provided:

Engineers available to service machinery overseas

GB/T 28001-2001,OHSAS18001:1999:Passed

Crane traveling limited switch:Included

Motor:High quality,famous brand

__________________________________________________

Application:Widely

Max. Lifting Load:100T

Place of Origin: Henan China (Mainland)

Certification: CE/SGS/GOST/ISO

GB/T 24001-2004 idt ISO14001:2004:Passed

Current overload protection system:Included

Emergency stop system:Included

Electric main parts:Siemens brand

__________________________________________________

Packaging & Delivery

Packaging Detail:Electricals and other parts are packed by high quality

plywood crates. Main beam packaged by plastic film and woven plastic cloth.

Delivery Detail: Within 45days after receiving your deposit

__________________________________________________

Specifications

Container Gantry Crane Loading/unloading containers with high efficiency, CE/ISO/SGS Certificate Loading capacity:10~100t

Rail Mounted Container Crane - (RMG) Gantry Cranes

Capacity: 20t/10t ,32t/10t ,36t/16t, 40t,50t,65t,

Usage: container terminals, open storage yards and along the railway lines to load or unload container

Technical Introduction:

The electrical equipment is accommodated in robust steel plate control cubicles.

All movement can be switched off by actuating the emergency-off switch at the control station via a main contactor.

The entire equipment is easy to install and dismantle due to the use of threaded bolts and top-hat rails. Cable inlet from the cable gland.

Power supply cable and control cable along the girder

A protective earth conductor is fitted as standard, a crane switch is provided.

Travel end switches, long and cross travel limited y means of preliminary and final limited switches and overload protection:

Design Structure

it runs on a runway at the floor level. The bridge is supported by a pair of rigid steel legs which are carried by a pair of end trucks along

the floor level runway.

Design Structure

it runs on a runway at the floor level. The bridge is supported by a pair of rigid steel legs which are carried by a pair of end trucks along the floor

level runway.

Mechanical feature

Double welding box girder, DIN/FEM standard deflection

Steel tube legs

Material Fe37 or Fe52

Whole length CNC cutting for complete web plate, high deflection accuracy

High quality autometic welding and NDT inspection

Shot-blasting Sa2.5 for complete girder after welding, stress release

Epoxy zinc rich high quality paiting, 2x2 with 140um

10.9 class High tension bolts mouting between girder and legs, life time safety connection

Vertical gear motor driving,more safety and smaller space

- Q:Did feminists skew the Obama stimulus plan towards women even though men are worse affected by the downturn?

- Yes, they didThe National Organization for Women (NOW), the Feminist Majority, the Institute for Women's Policy Research, and the National Women's Law Center soon joined the battle against the supposedly sexist bailout of men's jobsAt the suggestion of a staffer to Speaker of the House Nancy Pelosi, NOW president Kim Gandy canvassed for a female equivalent of the testosterone-laden 'shovel-ready'? terminology(Apron-ready was broached but rejected.) Christina Romer, the highly regarded economist President Obama chose to chair his Council of Economic Advisers, would later say of her entrance on the political stage, The very first email I got was from a women's group saying 'We don't want this stimulus package to just create jobs for burly men.'? They were right indeedOur incoming president did what many sensible men do when confronted by a chorus of female complaint: He changed his planHe added health, education, and other human infrastructure components to the proposalAnd he tasked Christina Romer and Jared Bernstein, Joseph Biden's chief economist, with preparing an extraordinary report that calculated not only the number of jobs the plan would likely create, but the gender composition of the various employment sectors and the division of largess between women and menRomer and Bernstein delivered The Job Impact of the American Recovery and Reinvestment Plan on January 10They estimated that the total number of created jobs likely to go to women is roughly 42 percentLest anyone miss the point, they added that since women had held only 20 percent of the jobs lost in the recession, the stimulus package now skews job creation somewhat towards womenWhat misandry can beat this? But of course, it is level headed Feminists like Christina Hoff Sommers who can see things for what they are, much less, be vocal about itCHSummers is a hero!

- Q:I was mowing with my Dixie Chopper 74quot; Excalibur ZTR and I lost control of the mower and it ended up in the bottom of my poolI can't get it out!! I've called AAA-no helpI've called all 3 of the towing compannies around here and they won't help meThe thing weighs 2100lbs!! Also, how bad will the damage be do you think? It's been in the pool for almost 9 days becasue noone will help meThanks.

- There are many tools that you can useTubing rollers, compact metal benders, rod benders, etc.

- Q:If I'm running multiple virtual machines (VMware) on one physical server host, and wanted to test an IDS with themIf the VMs are sending/receiving data to and from each other, does it leave the physical host, go out onto the network, or does it stay on the host? If all VMs are using the same physical NIC from the host, what MAC address problems come up on the switch?

- Sprayed in expanding foam insulation will do the job nicely, but it will be expensive because you'll have to hire an installerStandard fiberglass will be something you can do yourselfBuy the kind that has the batts in plastic sleevesMakes it less itchy, and there's no paper to mildewUse hanger wires called Tiger Teeth - they're stiff spring steel wires that you push up from the bottomThe ends are pointed and stick in to the joists; they arch up and support the fiberglassUse about four wires per standard batt.

- Q:What I remember is that there was this mother and she has a sonThey moved to a big houseAfter that, the boy discovered this quot;roomquot; (it's like an elevator) with thick walls and sort of security system insideThen these bad guys began to taunt the mother into letting them inside the big houseThe mother and the son were scared so they went in that quot;roomquot; and locked themselves inThen the guys did almost everything to get through that room while the mother and son desperately calls for help.I tried to describe it the way I remember it so there might be inaccurate details.

- finely mince or crush the garlic mix with some softened butter add some minced parsley (or dried) add a couple pinches of oregano and some salt and pepper to tastespread on your preferred bread, and if you like sprinkle some grated parmesan on topgrill on the BBQ or toast in the oven

- Q:preferably a text based game

- The soft drink was first sold to the public at the soda fountain in Jacob's Pharmacy in Atlanta on May 8, 1886

- Q:Why won't my Time Machine work?

- You are seriously luck that a ruined pan is the only damageHopefully you don't get toxic poisoning from cooking in the can, and you are luck the can didn't explodeNEVER EVER cook food in something that is not designed for cooking

- Q:Think if you are taking a car out on a track, want it to be fast which one would you choose?

- Toms is the best.try different versions of itim happy with itthe mouth wash is good too

- Q:a 100 lbs bucket with 500 lbs of sand in it is lifted by a crane to 80ft in the air at a rate of 2ft per second, but sand simultaneously leaks out through a hole at 3 lbs per second.

- If you can find the amount of sand at the start and at the end, you can average the before weight and the after weightSo then in the formula in your first answer Work done weight distance you can use average weight At 2ft per second, it'll take 40 seconds to lift it to 80 ftOver 40 seconds, the amount of sand lost is 120 lbsSo average 500 and 380 and plug that into the formula.

- Q:im a tutor and on this wednesday, i will start advertising my tuition posters in my neighbourhoodbut i dont know where to stick itwhere should i stick my posters where people/parents can see/notice?a) near the elevatorsb) near the mailboxc) stairsd) other places

- Eat the skins of fruit and drink more waterhow often do you expect to go? have your eating habits changed? I find wheetabix to be excellend addition and check the fibre content of food for example a bran english muffin has about 2 times the fibre of some breads per serving if you are concerned about anything go to your doctor!

- Q:I noticed in Mexico as well as in some middle eastern countries their entire buildings are made from concrete including the floorsFor example they have 3 story apartments built with each floor made from concreteHow the heck do you pour a concrete floor on a 2nd or 3rd story?

- What do you think the floors are made of in almost all skyscrapers, hospitals and other massive buildings? All the floors in the NY World Trade center towers were poured concreteI am sitting in a 5 story building myself made entirely of concreteThe answer is that concrete is a liquid in its initial form and it can be pumped through pipes and large hoses to whatever height it needs to be pouredThe Discovery Channel has shown some documentaries of high-rise construction on their Extreme Engineering program that depict these concrete pumping operationsI've worked in construction for over 30 years and have seen it many timesYou could probably find videos of the pumpers on YouTubeTwo or three story houses are easyAlmost any concrete contractor has pumps and boom-mounted hoses that can reach up that farAlso, some houses and other buildings can be made using pre-cast concrete planks, which are huge sections of floor that are cast on the ground, with reinforcement like rebar and stressed cables inside for strength, and then the slabs are lifted with a crane and laid on a concrete block or steel frameOne all the planks that make a floor are set, a thin layer of concrete grout is poured over the top - in that case it looks like a solid concrete pour over the whole levelWhere concrete is poured on upper floors it goes onto a formed steel pan supported by the structure below, or a temporary wooden platform that then gets stripped off once the concrete hardens and cures,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rail Mounted Container Gantry Crane

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords