QZ Overhead Crane with Grab Cap.2-20T, Crane with Grab, Overhead Crane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Profile

QZ overhead crane with grab is widely used to handle and transport the goods in port, factory, workshop and power plant.The working system of the QZ overhead crane with grab is heavy. The working classification the QZ overhead crane with grab is A6. All operations are handled in cab. Direction of door on platform toward driver’s cab: side, top and end. Rated lifting capacity contains the weight of the grab .

Open direction of grab is paralleling with the beam and pluming with the beam. The fetching device is a double-cylinder 4-rope grab bucket that is simple, reliable and can open at any height. The grab bucket is only used to take bulk material and make clear statement in the order if you want grab bucket that is used to take underwater or special material.The crane can be used for both indoor and outdoor operations and water-proof cloth is needed in outdoor operation.

Main structure feature

The overall QZ overhead crane with grab is made up of crane span structure, crane traveling mechanism, trolley mechanism, grab bucket,cab, electrical equipment and etc. The structural style of the QZ overhead crane with grab mainly adopts double girder and double rail winch with single trolley.

Technical specification of the main structure

Bridge span structure

The structure style of the trolley adopts double girder. The main stress part contains the main girder and end girder. And the assisted part includes trolley track, walking board, handrail, ladder and other auxiliary metal structures. The main girder adopts the right rail box girder structure, which has enough strength,rigidity and whole stability. The end girder adopts box girder structure where the end girder and main girder is connected with rigid coupling.

Lifting mechanism

On the trolley of the QZ overhead crane with grab, it is equipped with two sets of winch mechanisms. Each winch mechanism adopts twin drum, which is set symmetrically. Separately, each winch mechanism can handle the holding rope and open-close rope of the grab bucket with convenient operation, stable work and high productivity.

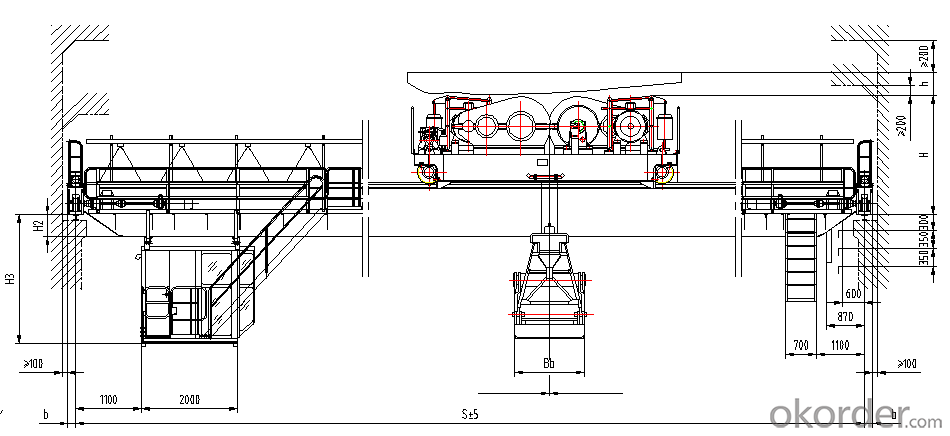

Sketch

Technical specification

Lifting capacity | t | 5 | 10 | ||||||||||||||||||||||||||||||

Span | m | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | ||||||||||||||||

Max.lifting height | m | 20 | 18 | ||||||||||||||||||||||||||||||

Working class | A6 | A6 | |||||||||||||||||||||||||||||||

Speed | Lifting | m/ min | 39.2 | 39.3 | |||||||||||||||||||||||||||||

Trolley traveling | 44.6 | 45.9 | |||||||||||||||||||||||||||||||

Crane traveling | 93.6 | 113.6 | 112.5 | 101 | |||||||||||||||||||||||||||||

W | 4000 | 4050 | 5000 | 4000 | 4100 | 5000 | |||||||||||||||||||||||||||

S1 | 1635 | 2015 | |||||||||||||||||||||||||||||||

S2 | 1635 | 1850 | |||||||||||||||||||||||||||||||

b | 230 | 230 | 260 | ||||||||||||||||||||||||||||||

H | 1876 | 1926 | 2078 | 2168 | |||||||||||||||||||||||||||||

H1 | 765 | 850 | 815 | 940 | |||||||||||||||||||||||||||||

H2 | 128 | 228 | 328 | 478 | 628 | 728 | 878 | 1028 | 180 | 230 | 380 | 390 | 540 | 690 | 840 | 940 | |||||||||||||||||

H3 | 2548 | 2648 | 2748 | 2898 | 3048 | 3148 | 3298 | 3448 | 2600 | 2650 | 2800 | 2810 | 2960 | 3110 | 3260 | 3360 | |||||||||||||||||

h | 850 | 700 | |||||||||||||||||||||||||||||||

Max.wheel load |

KN | 75 | 80 | 87 | 95 | 102 | 113 | 122 | 130 | 113 | 121 | 131 | 142 | 152 | 162 | 172 | 180 | ||||||||||||||||

Grab bucket | Model | U | 113 | 109 | 110 | 105 | 106 | 101 | 102 | 127 | 123 | 124 | 119 | 120 | 115 | 116 | |||||||||||||||||

Type | Light | Medium | Heavy | Extra-heavy | Light | Medium | Heavy | Extra-heavy | |||||||||||||||||||||||||

Volume | m³ | 2.5 | 1.5 | 1 | 0.75 | 5 | 3 | 2 | 1.5 | ||||||||||||||||||||||||

Density of material | t/m³ | ≤1 | >1~1.7 | >1.7~2.5 | >2.5~3.3 | ≤1 | >1~1.7 | >1.7~2.5 | >2.5~3.3 | ||||||||||||||||||||||||

Dead wight | kg | 2633 | 2549 | 2615 | 2506 | 2568 | 2479 | 2546 | 4800 | 4803 | 4866 | 4850 | 4913 | 4730 | 4793 | ||||||||||||||||||

Main dimension | D | 3120 | 2740 | 2740 | 2530 | 2530 | 2340 | 2340 | 3900 | 3430 | 3430 | 3220 | 3220 | 2920 | 2920 | ||||||||||||||||||

Ba | 2200 | 1950 | 1950 | 1800 | 1800 | 1650 | 1650 | 2700 | 2400 | 2400 | 2200 | 2200 | 1960 | 1960 | |||||||||||||||||||

Bb | 1500 | 1354 | 1354 | 1238 | 1238 | 1160 | 1160 | 2060 | 1754 | 1754 | 1528 | 1528 | 1416 | 1416 | |||||||||||||||||||

Recommended steel rail | 43kg/m or QU70 | ||||||||||||||||||||||||||||||||

Power source | Three-phase AC 50Hz 380V | ||||||||||||||||||||||||||||||||

Technical specification

Lifting capacity | t | 16 | 20 | ||||||||||||||||||||||||||||

Span | m | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | ||||||||||||||||||

Max.lifting height | m | 28 | 26 | ||||||||||||||||||||||||||||

Working class | A6 | A6 | |||||||||||||||||||||||||||||

Speed | Lifting | m/ min | 41.8 | 45.7 | |||||||||||||||||||||||||||

Trolley traveling | 43.2 | 43.2 | |||||||||||||||||||||||||||||

Crane traveling | 98 | 87.3 | 87.3 | ||||||||||||||||||||||||||||

W | 4800 | 5000 | 4800 | 5000 | |||||||||||||||||||||||||||

S1 | 2305 | 2635 | |||||||||||||||||||||||||||||

S2 | 2060 | 2485 | |||||||||||||||||||||||||||||

b | 260 | 300 | 300 | ||||||||||||||||||||||||||||

H | 2385 | 2535 | 2739 | ||||||||||||||||||||||||||||

H1 | 940 | 1090 | 1090 | ||||||||||||||||||||||||||||

H2 | 394 | 544 | 544 | 694 | 794 | 894 | 246 | 390 | 546 | 696 | 796 | 896 | |||||||||||||||||||

H3 | 2814 | 2964 | 2964 | 3114 | 3214 | 3314 | 2666 | 2816 | 2966 | 3116 | 3216 | 3316 | |||||||||||||||||||

h | 660 | 482 | |||||||||||||||||||||||||||||

Max.wheel load | KN | 206 | 218 | 233 | 247 | 257 | 269 | 229 | 243 | 254 | 270 | 279 | 293 | ||||||||||||||||||

Grab bucket | Model | U | 141 | 137 | 138 | 133 | 134 | 129 | 130 | 155 | 151 | 152 | 147 | 148 | 143 | 144 | |||||||||||||||

Type | Light | Medium | Heavy | Extra-heavy | Light | Medium | Heavy | Extra-heavy | |||||||||||||||||||||||

Volume | m³ | 8 | 4.8 | 3.2 | 2.5 | 10 | 6 | 4 | 3 | ||||||||||||||||||||||

Density of material | t/m³ | ≤1 | >1~1.7 | >1.7~2.5 | >2.5~3.3 | ≤1 | >1~1.7 | >1.7~2.5 | >2.5~3.3 | ||||||||||||||||||||||

Dead wight | kg | 7840 | 7993 | 8143 | 8008 | 8159 | 8155 | 8305 | 9812 | 10098 | 10287 | 9976 | 10123 | 9780 | 10206 | ||||||||||||||||

Main dimension | D | 4380 | 4050 | 4050 | 3750 | 3750 | 3430 | 3430 | 5000 | 4500 | 4500 | 4000 | 4000 | 3800 | 3800 | ||||||||||||||||

Ba | 3200 | 2820 | 2820 | 2600 | 2600 | 2350 | 2350 | 3500 | 3200 | 3200 | 2900 | 2900 | 2400 | 2400 | |||||||||||||||||

Bb | 2350 | 2078 | 2078 | 1792 | 1792 | 1628 | 1628 | 2478 | 2288 | 2288 | 1892 | 1892 | 1892 | 1892 | |||||||||||||||||

Recommended steel rail | QU70 or □ 90×90 | ||||||||||||||||||||||||||||||

Power source | Three-phase AC 50Hz 380V | ||||||||||||||||||||||||||||||

Traveling mechanism of the trolley

Supported by four wheel of the trolley, the traveling mechanism of trolley of the QZ overhead crane with grab adopts a set of independent driven system to complete centralized drive on the trolley. The ratio of the drive wheel is 1:2. The transmission pattern of the trolley is: by means of gear coupling, one motor can drive one vertical type reducer. The two low speed shafts and two wheel shafts are connected with coupling and transmission shaft. The ratio of the drive wheel is 1:2.

Crane traveling mechanism

Supported by four wheel of the crane, the traveling mechanism of crane of the QZ overhead crane with grab adopts a set of independent driven system to complete centralized drive on the crane. The ratio of the drive wheel is 1:2. The transmission pattern of the crane is: one motor drives one reducer by means of coupling. And the the low speed shaft of the reducer and wheel shaft is connected with coupling. When the crane is started, the driving wheel will be not-slip. When the crane is braked, it is stable and smooth.

Protection and indicator

The QZ overhead crane with grab is set with emergency switch on the power off. Under the condition about the emergency, it can cut off the total power source of the crane.

The electric motor is equipped with complete protection devices. It can protect the QZ overhead crane with grab when it is in over current and short circuit, efficiently.

All of the door of the handrail is equipped with safety electric interlock.

Overload limiting device:

The QZ overhead crane with grab is equipped with overload limiting device. When the load reaches 90% of the rated load, the display instrument will send a alarm automatically. When the load reaches the 105% of the rated load, the QZ overhead crane with grab will cut off the total power source of lifting mechanism automatically.

The protective device of upper limiting position.the lifting mechanism of the hook is set with inhibiting device. When the hook has been lifted at the extreme height it will cut off the power source of the lifting mechanism.

Stroke limiter: on both sides of the crane and trolley are set with stroke limiter. When the crane and the trolley arrive at the extreme position, it will cut off the power source automatically. Also, it can travel in a reverse direction.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

QZ Overhead Crane with Grab Cap.2-20T, Crane with Grab, Overhead Crane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords