Quenched and Tempered Steel SAE4140 SAE4145 SAE4340 SCM440 42CrMoS4 708M40 Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quenched and Tempered Steel SAE4140 SAE4145 SAE4340 SCM440 42CrMoS4 708M40 Steel Round Bar

Products Details

1. Chemical Composition and Mechanical Properties(In Quenched & Tempered State)

Material | 4140 | ||

Chemical Composition | Mechanical Properties(In Quenched & Tempered State) | ||

C | 0.38-0.45 | Tensile strength(MPA) | ≥1080 |

Si | 0.17-0.37 | Yield strength (MPA) | ≥930 |

Mn | 0.50-0.80 | Elongation(δ5/%) | 12 |

Cr | 0.90-1.20 | Reduction in Area (ψ/%) | 45 |

Mo | 0.15-0.25 | Impact (J) | 63 |

P | ≤0.035 |

Hardness |

≤217HB |

S | ≤0.035 | ||

Cu | ≤0.30 | ||

Ni | ≤0.30 | ||

2. Product Application Areas

Our products have been used in all kinds of areas, such as aviation,aerospace,navigation,nuclear energy,chemical industry,electronic information,achine manufacture, petrochemical, automotive,instrument and meter, Communication ,transportation, and medical instruments, etc.

3. Similar steel grade & equivalent steel materials

USA | Japanese | Gemany | British | France | International | Chinese |

ASTM&AISI&SAE | JIS | EN DIN | EN BS | EN NF | ISO | GB |

4140 | SCM440 | 42CrMo4 1.7225 | 42CrMo4 1.7225 | 42CrMo4 1.7225 | ------ | 42CrMo |

Product Sales Information

Material | 4140 steel round bar |

Size | Diameter:20mm-1000mm Length:500mm-6000mm |

Origin place | Made In China |

Delivery Condition | Hot rolled,cold drawn,forged |

Surface require | Black,grinding,bright,polish |

Heat treatment | Quenched,Tempered,annealed |

Packing | seaworthy packing ,wooden case ,carton,woven bag or at client's requires |

Delivery time | In 10-50 days |

Trade Term | EXW,FOB,CIF |

Payments | T/T or L/C at sight |

Port | China main Port,such as shanghai,Dalian,Shenzhen port. |

MOQ | 1 Ton |

Company Main Products

Alloy Steel | 4140, 4142, 42CrMo4, 1.7225, SCM440, 4130, SCM430, 25CrMo4, 1.7218, 34CrNiMo6, 1.6582, 4340, SNCM439, 36CrNiMo4, 1.6511, SACN645, 1340, SMn438, SNC236, |

Tool Steel | H13, 1.2344, SKD61, D2, SKD11, 1.2379, 1.2510, 01, SKS3, 95MnWCr5, D3, SKD1, 1.2419, SKS31, H21, SKD5, 1.2581, P20, 35CrMo7, 1.2738, 1.2316, M2 |

Bearing Steel | GCr15, 52100, SUJ1, SUJ2, 100Cr6, 1.2067, 55C, 8620, 4320, 9310, 440C, M50 |

Spring Steel | 9260, SUP6, SUP7, 1.7108, 54SiCr6, 1.7102, 5155, SUP9, 1.7176, 5160, 1.7177, 6150, SUP10, 51CrV4, 1.8159 |

Stainless Steel | 321, sus321, 1.4541, 304, SUS304, 1.4301, 410, SUS410, 1.4006, 420, 1.4021, 1.4028, 434, 1.4113, 316L, SUS316L, 1.4435, 630, 1.4542, 431, 1.4057, |

Products Show

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

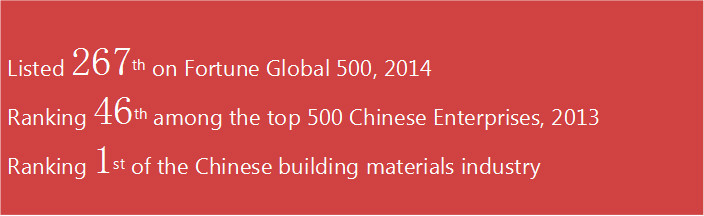

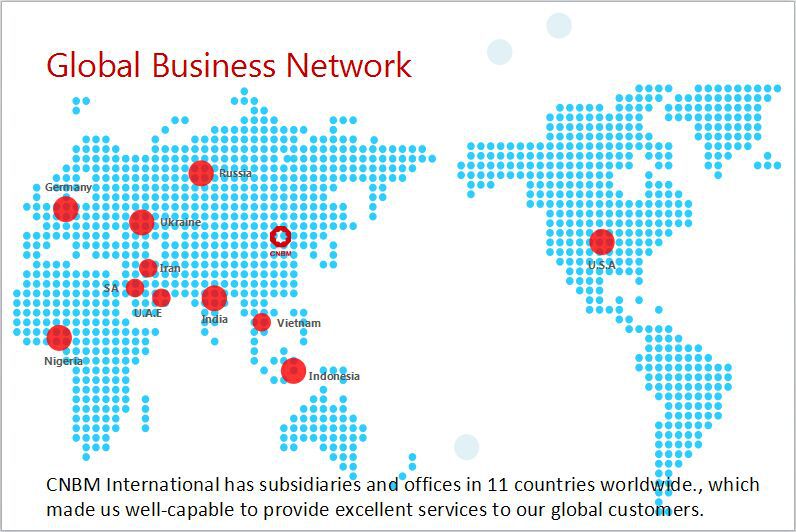

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q:Can steel round bars be coated or painted?

- Steel round bars have the capability to undergo coating or painting. The purpose of coating or painting steel round bars is manifold; it prevents corrosion, enhances aesthetics, and provides additional protection against environmental factors. There are several methods available for applying coatings and paints to steel round bars, including powder coating, electroplating, or wet paint application. These processes involve first preparing the surface of the steel round bar by removing any existing rust or contaminants, and then applying the chosen coating or paint. The selection of the appropriate coating or paint depends on the specific requirements of the steel round bars, such as their intended use, environmental conditions, and desired appearance. By coating or painting steel round bars, their lifespan can be significantly extended, their visual appeal can be improved, and their durability can be ensured in a wide range of applications.

- Q:What is the difference between a cold finished and a hot rolled steel round bar?

- A cold finished steel round bar and a hot rolled steel round bar differ in their manufacturing processes and resulting properties. Cold finished steel round bars are manufactured through a cold drawing process, where the steel is pulled through a die at room temperature. This process results in a smooth, polished surface with tight dimensional tolerances. The cold drawing process also enhances the strength, hardness, and overall mechanical properties of the steel. Cold finished steel round bars are often preferred for applications where precision and a smooth surface are crucial, such as in machinery, automotive parts, and tools. On the other hand, hot rolled steel round bars are manufactured by heating the steel to a high temperature and then rolling it through a series of rollers. This process allows for the shaping and forming of the steel while it is in a pliable state. Hot rolled steel round bars have a rough, scaled surface and looser dimensional tolerances compared to cold finished bars. They also tend to have a slightly lower strength and hardness than their cold finished counterparts. Due to their more affordable cost and ease of production, hot rolled steel round bars are commonly used in construction, structural components, and general fabrication. In summary, the main differences between cold finished and hot rolled steel round bars lie in their manufacturing processes and resulting properties. Cold finished bars offer enhanced strength, precision, and a smooth surface, making them suitable for applications requiring high precision and mechanical performance. Hot rolled bars, on the other hand, have a rougher surface and looser tolerances, but their affordability and ease of production make them a popular choice for general applications.

- Q:How many tons of pressure can the round steel of 70 inches bear?

- As the diameter of about 11.5 cm diameter 180 cm long in the middle of the force which kind of force will be smaller if the curvature is hollow capability hollow wall thickness to achieve much greater strength than solid to do not understand what the best please say a little more thank you good answer is a plus

- Q:What are the different types of steel round bars used in the automotive steering systems?

- In automotive steering systems, there exists a range of steel round bars with distinctive properties and advantages. 1. Carbon Steel Round Bars: These round bars are extensively utilized in automotive steering systems due to their superior strength and durability. They are suitable for various steering components like tie rods and drag links. Additionally, carbon steel round bars are cost-effective and readily accessible, making them a popular choice in the automotive industry. 2. Alloy Steel Round Bars: By incorporating alloying elements such as chromium, nickel, and molybdenum into carbon steel, alloy steel round bars enhance their strength, hardness, and wear resistance. They are particularly useful in high-stress areas of the steering system, including steering shafts and steering knuckles, where additional strength is required. 3. Stainless Steel Round Bars: Stainless steel round bars are renowned for their exceptional resistance to corrosion, making them ideal for steering components exposed to harsh environments or moisture. Steering column shafts and tie rod ends frequently incorporate stainless steel round bars. 4. Tool Steel Round Bars: Steering system components that demand high hardness, wear resistance, and toughness often utilize tool steel round bars. These bars are commonly employed in the production of steering gears and other precision steering components. 5. High-Strength Low-Alloy (HSLA) Steel Round Bars: HSLA steel round bars, a type of alloy steel, offer a favorable balance between strength, toughness, and formability. Lightweight steering system components often employ HSLA steel round bars to reduce weight while maintaining structural integrity. Ultimately, the selection of steel round bars in automotive steering systems depends on factors such as the specific application, desired strength, durability, and corrosion resistance. Manufacturers carefully choose the appropriate steel type to ensure optimal performance and safety in steering systems.

- Q:What are the advantages of using manganese-alloy steel round bars?

- There are several advantages of using manganese-alloy steel round bars in various applications. Firstly, manganese-alloy steel round bars offer excellent strength and toughness. The addition of manganese to the alloy enhances the hardness and durability of the steel, making it suitable for high-stress applications. This makes it an ideal choice for industries such as construction, mining, and manufacturing. Secondly, manganese-alloy steel round bars have excellent wear resistance properties. The presence of manganese in the alloy significantly improves the steel's ability to resist wear, abrasion, and impact. This makes it a preferred choice for components that are subject to heavy usage and constant friction, such as gears, shafts, and axles. Additionally, manganese-alloy steel round bars exhibit good machinability. They can be easily shaped, cut, and formed into various shapes and sizes, which makes them versatile for different applications. This characteristic allows for efficient manufacturing processes and reduces production time and costs. Moreover, manganese-alloy steel round bars have excellent corrosion resistance. The presence of manganese in the alloy provides a protective layer that helps prevent the formation of rust and corrosion, even in harsh environments. This makes them suitable for applications where exposure to moisture, chemicals, or extreme temperatures is a concern. Lastly, manganese-alloy steel round bars offer cost-effectiveness. Compared to other high-performance alloys, manganese-alloy steel is relatively more affordable while still providing many of the same benefits. This makes it a cost-effective choice for many industries looking for a durable and reliable material without breaking the bank. Overall, the advantages of using manganese-alloy steel round bars include superior strength, excellent wear resistance, good machinability, corrosion resistance, and cost-effectiveness. These qualities make them a popular choice in various industries where durability, reliability, and cost-efficiency are essential.

- Q:What are the advantages of using aluminum-silicon alloy steel round bars?

- Aluminum-silicon alloy steel round bars offer numerous benefits: 1. Enhanced lightweight: By combining aluminum with silicon, the round bars become even lighter, making them easier to handle. This is especially advantageous in industries where weight reduction is crucial, like aerospace and automotive. 2. Exceptional strength: The mechanical properties of aluminum-silicon alloy steel round bars, such as high tensile and good yield strength, allow them to withstand heavy loads and provide structural integrity in various applications. 3. Resistance to corrosion: These round bars exhibit excellent resistance to corrosion, making them suitable for environments with moisture or chemicals. Thus, they can be used in applications exposed to harsh conditions or corrosive substances. 4. Efficient thermal conductivity: The round bars' excellent thermal conductivity facilitates efficient heat transfer. This property is particularly beneficial in industries like heat exchangers, where effective thermal management is essential. 5. Easy machinability: Aluminum-silicon alloy steel round bars are relatively easy to machine, allowing for precise shaping and forming. This makes them ideal for applications requiring intricate designs or specific dimensions. 6. Cost-effective solution: Compared to other materials, aluminum-silicon alloy steel round bars offer a cost-effective solution due to their low production and maintenance costs. This makes them popular in construction, automotive, and manufacturing industries. 7. Environmentally friendly: Aluminum-silicon alloy steel round bars are highly recyclable, which is crucial in today's environmentally conscious world. Recycling these alloys requires less energy compared to primary production, making them a sustainable choice. In conclusion, the advantages of aluminum-silicon alloy steel round bars encompass their lightweight nature, high strength, corrosion resistance, thermal conductivity, machinability, cost-effectiveness, and recyclability. These properties make them a versatile material for a wide range of applications across various industries.

- Q:Can steel round bars be coated?

- Indeed, it is possible to coat steel round bars. Coating them yields numerous advantages, such as enhanced resistance to corrosion, increased durability, and improved visual appeal. The most commonly utilized coatings for steel round bars encompass galvanized coatings, epoxy coatings, and powder coatings. Galvanized coatings encompass the application of a zinc layer onto the steel's surface, which provides exceptional protection against corrosion. Epoxy coatings, on the other hand, find common application in industrial settings due to their remarkable chemical resistance and ability to withstand harsh environments. Powder coatings, involving the electrostatic application of a dry powder, are then cured under heat to form a robust and protective layer. These coatings can be employed on steel round bars to safeguard against rust and other forms of corrosion, thereby rendering them suitable for a broad scope of applications across various industries, including construction, manufacturing, and automotive.

- Q:Can steel round bars be galvanized?

- Yes, steel round bars can be galvanized. Galvanizing is a process of coating steel with a layer of zinc to protect it from corrosion. This process is commonly used to increase the longevity and durability of steel products, including round bars.

- Q:Are steel round bars susceptible to corrosion?

- Yes, steel round bars are susceptible to corrosion.

- Q:What is the maximum weight of a steel round bar?

- The maximum weight of a steel round bar depends on its diameter and length. Steel round bars come in various sizes and weights, so it is important to specify the dimensions in order to determine the maximum weight. The weight of a steel round bar can be calculated using the formula: weight = volume × density, where volume can be calculated as πr²h (pi times the square of the radius times the height) and density is the specific weight of steel (approximately 7850 kg/m³). By plugging in the appropriate values, you can calculate the maximum weight of a steel round bar.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Quenched and Tempered Steel SAE4140 SAE4145 SAE4340 SCM440 42CrMoS4 708M40 Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products