QM16200 ACCU-LOCK MACHINE VICE WITHOUT SWIVEL BASE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

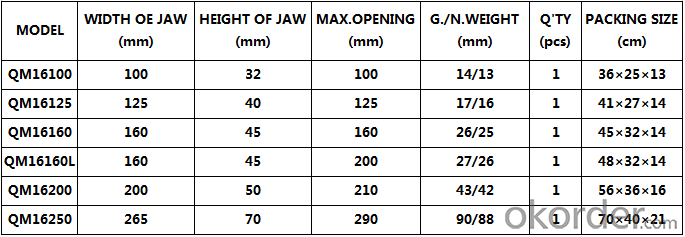

QM Series MachineVice

Performance and character:

1. It is one of main attachmentsfor milling、drillingmachine ,it is particularly suitable for the finishing of precision parts.

2. The accuracy of vice (parallelismand squareness) is 0.025mm/100mm.

3. The special segment in themovable jaw forces the vertical pressure downward when the horizontal pressureworks, so that this jaw does not lift the work piece.

4. Four positions allow extracapacity to change opening of jaw.

- Q:Do you use a hammer to hit the handle with a clamp?

- The following statement is true (A) A. use A hammer to hit the handle when clamping the workpiece with A vice B. saw a blade tightening with two fingers to tighten the butterfly nut. It feels hard to pull the saw blade In order to increase the efficiency of sawing and cutting, the force should be applied properly when pulling the handsaw The iron filings of the vice of a vice, which can be blown off by the mouth or by hand

- Q:Is the screw of a vice clamp a silk stick? How do you choose a screw with the same principle? The device requires a general assembly

- The screw on the top of the vice clamp is actually a silk pole. The first thing you don't know is how big a clamping device you want to do. It is recommended that you choose a silk rod that is no less than thirty in diameter (the specific pitch is chosen according to the actual situation). Note: the minimum material of the material is 45 steel. Silk mother chooses tin bronze silk mother.

- Q:How to calibrate the CNC milling machine tongs

- Find the design check to confirm that the semi-circle face is right Angle to the top.

- Q:Ask questions! How large a bench vice is a carpenter?

- There are conditions for a 5-inch, heavy-duty, working, cleaning tool. Remember to buy a good brand.

- Q:How to draw a vice assembly drawing

- Complete the complete picture, deepen the drawing line, draw the section line, mark the necessary dimensions, the tolerance and technical requirements, mark the parts serial number, fill in the detail form and the title bar. Thank you for your trouble! If you don't understand, please continue to ask...

- Q:What does Taiwan's vice President stand for

- The inches here are the units used in the past: inches. The length of an inch is a metric unit of 25.4mm, and a metric system of 8 inches is 203.2mm.

- Q:How to position the pongs

- Flat vice of the base, there is a groove, groove in the two ends of the each have a positioning block, using positioning, the positioning block into the workbench T slot, the vise base location can be completed. Because the vise has a back wheel, first use owe is correct position of the jaw, can in the clamp mouth with a long flat plate, dial indicator adsorbed on the bed, dial indicator first come into contact with the plate, pull the workbench check parallel-jaw vice, parallel, finally fixed fastening screws.

- Q:All of the double force vice is designed with the same high design?

- The standard family is different from each other, and I understand that most of them are lower than the accuracy tables above you What is alleged to be the vice of the vice that is the same as the brand only, is to tell the client to be able to be able to be able to be able to be able to use a few times

- Q:How do milling machine tongs correct

- Attach the magnetic seat to the column and attach the scale and the probe microcontact.

- Q:Numerical control milling machine vice school table

- With a dial indicato.I hope my answer will help you.r

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

QM16200 ACCU-LOCK MACHINE VICE WITHOUT SWIVEL BASE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products