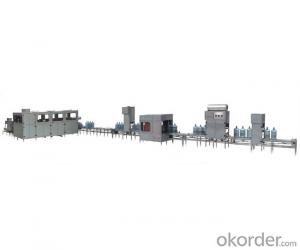

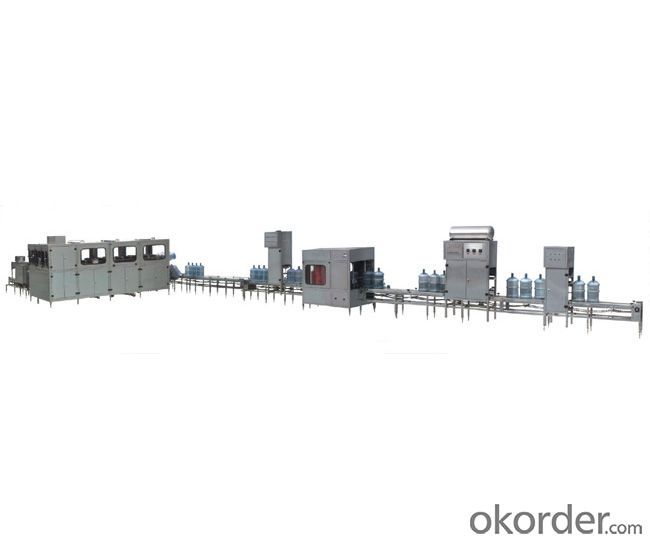

QGF Series Drum Filling Production Line QGF-400

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

CMAX Packing is a professional company specializing in R & D, manufacturing, technical service and sales of beer and beverage packing machinery.

Among the products, RCGF series, CGF series, DCGF series bottle packing and QGF series barrel packing beverage production lines and QHS series beverage mixer are all designed and made on the base of importing the advanced technology from German, Italy and Japan and its technology keeps the same level as international.

Also the company provides technical consultation, factory planning, installing and adjusting technological train and other services.

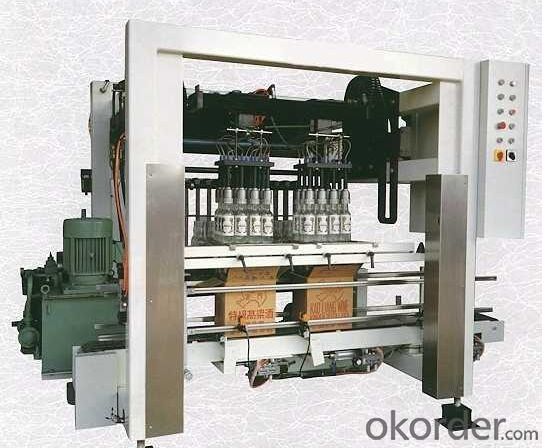

QGF series drum filling production line:

Usage:

It is especially used in 3 gallons, 5 gallons drum-packed pure water, washing, filling and capping.

Characteristics:

The parts touching with water adopt high-quality stainless stee. The cylinder gear runs smoothly and the fixed position is correct. It adopts inserting-type washing technology to remove washing blind angle.

Main Technical Parameters:

Machine | Model | QGF-120 | QGF-240 | QGF-300 | QGF-400 | QGF-600 |

Capacity | 120 | 240 | 360 | 480 | 600 | |

Filling head | 1 | 2 | 3 | 4 | 5 | |

Overall size | 3700*1600*1800 | 4000*1500*1800 | 4000*1580*1800 | 4000*1580*1800 | 5000*1850*1900 | |

Power | Main machine | 3.8 | 6.8 | 8.8 | 11 | 11 |

Heating(kw) | 9 | 10 | 12 | 12 | ||

Compressed air | Air pressure | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

Air consumption | 0.2 | 0.2 | 0.3 | 0.4 | 0.5 | |

Lye | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

Circle water | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

Sterilizing water | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

Pure water | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

Pure water | 600 | 1000 | 1500 | 2000 | 2500 | |

FAQ:

1. why chose us?

China National Building Materials (Group) Corporation (CNBM), established in 1984,now is one of the largest state-owned group corporation in China, dealing with building materials & industrial equipment. Up to year 2010, CNBM Group's total asset is 20 billion USD and total staff is more than 100,000.CNBM International Corporation, specializes in designing & manufacturing of various

kinds of construction machinery, including tower crane, building hoist, etc. All the equipment produced by CNBM are compliant with the National level quality standard, and wins great reputation for their endurable performance in worldwide markets.

2.How about the shipment?

The delivery time is 20 days.

3. What about your service?

We have our factory, we can meet customers needs as soon as possible.

We have first rate professional technology and provide good after-sales service.

- Q:What are the main functions of packaging machinery?

- In order to meet the requirements of many customers, our company has learned from all aspects of the role of packaging machinery and equipment, so that we need customers for reference

- Q:What is the delay time of the packer's cross sealing?

- You can debug it yourself, set up a parameter, such as a delay of 1 second or a few seconds, look at the action of sealing, you know what time it is.

- Q:Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- . This is the importance of after-sales service. Qingdao Xun packaging machine models, can meet the needs of all levels.

- Q:What's the fastest packing machine?

- 3 ideal speed of the package can reach 70 packs, that is, 70*3 = 210., and now there are 4 packages abroad. But the bags are small.

- Q:What kind of reducer is commonly used in packaging machinery?

- There are many kinds of packing equipment, such as food packing, filling, quantitative packing, back channel packing and so on

- Q:Predecessors please point out: what is the future of packaging machinery industry?

- Hello, in recent years, Chinese packaging industry, although the annual growth rate ranked in the traditional industry for the first time, but in line with the international market, to accelerate the development of packaging technology, make its development to the economic, efficient, multi-functional direction. According to the development plan of Chinese national economy and to realize well-off life level, this year a few years for the packaging industry, the food industry to provide equipment for 100 billion yuan to 200 billion yuan, 80 billion yuan to 100 billion yuan to provide equipment for the "vegetable basket", this is a good opportunity for development of enterprises. At the same time, I learned from the relevant ministries, "95" period, will invest 10 billion yuan in the packaging industry to support and transform large and medium-sized packaging enterprises.

- Q:What is the price of a small jujube packing machine?

- Mainly see what some requirements, automatic metering packaging or vacuum packaging machine, after understanding can determine the price.

- Q:Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- You can consider the promotion above the industry website.Plus, you're the packaging machine for candy and cookies, and of course it's the maker of candy and cookies.

- Q:Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is recommended not to check the cursor, if the speed is stable, with the amount of speed (recommended to detect the angular speed of the drum) to detect, a closer speed will be smaller, you can do the implementation of the operation. If the speed is unstable, you can only use the scale. But the 2 one is marked out. The beginning and the end. A colleague detects the difference in velocity between the 2 displacements. The difference in speed means that the film is stretched and the excessive velocity is stopped directly, which means that the film has been stretched

- Q:What machine does the packing carton machine have?

- Do the carton machinery: corrugated production line / single machine, printing machine, polishing machine, laminating machine, mounting machine, die-cutting machine, book paste machine for package machinery: automatic sealing machine, automatic strapping machine

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

QGF Series Drum Filling Production Line QGF-400

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords