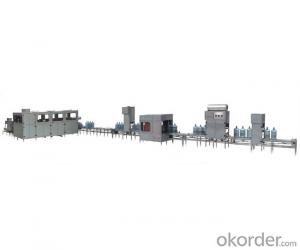

QGF Series Drum Filling Production Line QGF-300

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description QGF Series Drum Filling Production Line QGF-300:

CMAX Packing is a professional company specializing in R & D, manufacturing, technical service and sales of beer and beverage packing machinery.

Among the products, RCGF series, CGF series, DCGF series bottle packing and QGF series barrel packing beverage production lines and QHS series beverage mixer are all designed and made on the base of importing the advanced technology from German, Italy and Japan and its technology keeps the same level as international.

Also the company provides technical consultation, factory planning, installing and adjusting technological train and other services.

QGF Series Drum Filling Production Line QGF-300:

Usage:

It is especially used in 3 gallons, 5 gallons drum-packed pure water, washing, filling and capping.

Characteristics:

The parts touching with water adopt high-quality stainless stee. The cylinder gear runs smoothly and the fixed position is correct. It adopts inserting-type washing technology to remove washing blind angle.

Main Technical Parameters:

Machine | Model | QGF-120 | QGF-240 | QGF-300 | QGF-400 | QGF-600 |

Capacity | 120 | 240 | 360 | 480 | 600 | |

Filling head | 1 | 2 | 3 | 4 | 5 | |

Overall size | 3700*1600*1800 | 4000*1500*1800 | 4000*1580*1800 | 4000*1580*1800 | 5000*1850*1900 | |

Power | Main machine | 3.8 | 6.8 | 8.8 | 11 | 11 |

Heating(kw) | 9 | 10 | 12 | 12 | ||

Compressed air | Air pressure | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

Air consumption | 0.2 | 0.2 | 0.3 | 0.4 | 0.5 | |

Lye | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

Circle water | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

Sterilizing water | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

Pure water | Inside rinse | 20s*2 | 20s*2 | 20s*2 | 20s*2 | 20s*2 |

Outside spray | 20s*1 | 20s*1 | 20s*1 | 20s*1 | 20s*1 | |

Pure water | 600 | 1000 | 1500 | 2000 | 2500 | |

FAQ QGF Series Drum Filling Production Line QGF-300:

1. why chose us?

China National Building Materials (Group) Corporation (CNBM), established in 1984,now is one of the largest state-owned group corporation in China, dealing with building materials & industrial equipment. Up to year 2010, CNBM Group's total asset is 20 billion USD and total staff is more than 100,000.CNBM International Corporation, specializes in designing & manufacturing of various

kinds of construction machinery, including tower crane, building hoist, etc. All the equipment produced by CNBM are compliant with the National level quality standard, and wins great reputation for their endurable performance in worldwide markets.

2.How about the shipment?

The delivery time is 20 days.

- Q:What is the delay time of the packer's cross sealing?

- You can debug it yourself, set up a parameter, such as a delay of 1 second or a few seconds, look at the action of sealing, you know what time it is.

- Q:How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- Ceramic wall and floor tile is a special term used in building ceramics industry. It refers to the ceramic tile used for paving internal walls, exterior walls and floors.It includes:Glazed tiles: white glazed tile, colored shaddock tile, embossed glazed tile, mottled glazed tile, patterned glazed tile, mural glazed tile.Floor tile: paving brick, red floor tile, ceramic mosaic tile (ceramic mosaic), ladder brick.The exterior wall tiles, glazed tiles, glazed tiles, imitation brick, brick from #.

- Q:Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Now the standard of living has improved, basically the vacuum bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q:What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Molding: mainly used for thermosetting resins. There is a special molding machine. Molding pressure is much greater than the above. The mold structure is also more complex.

- Q:Color code positioning of packaging machinery

- The main products are: packaging machinery series of quantitative packing machine, vacuum packaging machine, packing machine, strapping machine, sealing machine, bag machine, carton forming machine, packing machine, winding machine, labeling machine, stacking machine, and the design of various transmission lines; at the same time, the production and sale of packing tape, stretch film and other packaging material.

- Q:The role of food packaging machinery

- 3) to achieve manual packaging can not achieve the operation, some packaging operations, such as vacuum packaging, inflatable packaging, body packing, isobaric filling, etc., are manual packaging can not be achieved, can only be achieved by mechanical packaging.(4) can reduce labor intensity, improve the working conditions of the labor intensity of manual packaging, such as volume, weight heavy manual packaging products, both the consumption of physical strength, and safety; and for small and light products, due to high frequency, easy to make the action monotonous, worker occupation disease. Carton folding machine(5) in favor of labor protection for some serious impact on health products, such as serious dust, toxic products, irritating, radioactive products, manual packaging is a health hazard, and packaging machinery can be avoided, and can effectively protect the environment from being polluted.(6) it can reduce the cost of packing and save the storage and transportation expenses. It can reduce the volume and reduce the packing cost by compressing and packing the loose products, such as cotton, tobacco leaf, silk and hemp. At the same time, due to the reduction of large volume, in order to save storage capacity, reduce storage costs, is conducive to the transport.(7) ensure product health of certain products, such as food and drug packaging, according to the health law is not allowed to use manual packaging, because it will pollute the products and packaging machinery to avoid direct contact with the staff of food and medicine, to ensure the quality of health.

- Q:What is the name of the paper used in packing machine parts and yellow?

- Vapor phase rust proof paper is coated with vapor phase corrosion inhibitor on the base of antirust base paper (surface like kraft paper, but with chloride ion and sulfate ion limit requirement)

- Q:Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Sometimes, this wine packaging PigHead, with different types of vacuum packaging machine

- Q:Working principle of packing machine

- In the first step, the wrapping paper is pulled down by a bag pulling motor, and then the paper part is supplied with paper according to the signal of the paper feeding sensor, and the wrapping paper is formed through the forming part of the shaper

- Q:Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is suggested that displacement or velocity should be detected on the transport path of the membrane. Is a more reliable control signal. Of course, you can also detect the angular speed of the recovery drum, such as a code dial and other simple institutions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

QGF Series Drum Filling Production Line QGF-300

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords