QB Series Peripheral Pumps with Brass Impellers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 400 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Application of the pump:

1> Clean Water without abrasive particles, non-aggressive liquid.

2> Domestic use.

3> In particular for delivering water in combination with small pressure sets and for irrigation.

4> Installed in enclosed places, or at least protected against inclement weather.

2. Operating conditions.

1> Suction lift up to 8m.

2> Liquid temperature up to +40℃

3> Ambient temperature up to +40℃。

4> Max. working pressure: 6bar.

3. Motor description:

1> 2-pole induction motor: 50Hz.

2> Insulation: Class B.

3> Protection: IP44.

4> With capacitor and thermal overload protection.

4. Material of the pumps:

1> Pump body: Cast Iron.

2> Motor bracket: Aluminum.

3> Impeller: Brass.

4> Shaft with rotor: Stainless steel or CS45#

5> Mechanical seal: Ceramic-Graphite.

6> Copper Winding.

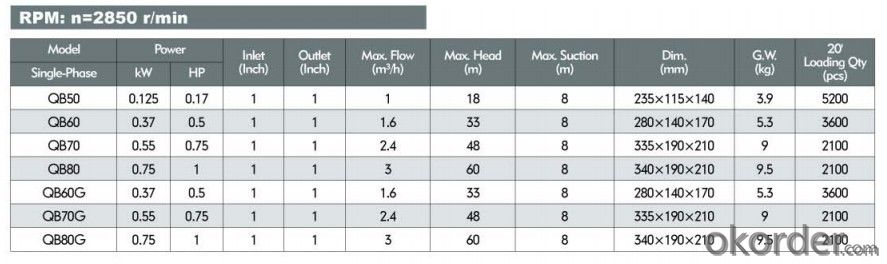

5. Detailed specification for the pumps:

6. FAQ

1). Can I get trained on CNBM products?

Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

2). Are your pumps cheaper than those of your competitors?

CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

3). How long is your warranty?

Unless otherwise expressly authorized in writing, by specifying a longer period or different conditions, CNBM states that, for a period of twelve (12) months from delivery date, all Products supplied are free from defects in materials and workmanship, and conform to the applicable specifications. Either the delivery documentation or the invoice must be provided to prove delivery date. In absence of such documents, the production date appearing on the product label may suffice.

- Q:If the suction pump does not have enough suction range, you need to add a vacuum pump to increase the suction stroke. How do you install the suction pipe of the vacuum pump? Water pump impeller is not closed, it is normal that the vacuum pump is unable to pump suction pipe to a vacuum, is it because the water pump outlet pipe connected to the role of the check valve? But the water pump, outlet pipe, check valve sealing performance can achieve the function of non leakage?

- Vacuum suction principle of self suction pump:Assuming that the pump connected with the water inlet of a sealed container, the container has plenty of water, since the start of a water pump, water is thrown out of the water impeller pump body, water inlet seal vessel due to the extraction of water to form a vacuum cavity, this assumption will be connected to vacuum cavity and exposed to atmospheric conditions of water, water at atmospheric pressure under the effect of entry into the vacuum chamber".

- Q:How many kilograms of water pump are there in the automatic washing machine on the market?

- Suitable for supporting high pressure sprayer, portable car washer. Water pump with overflow circuit. And comes with pressure switch, overflow switch double insurance

- Q:What does centrifugal pump mean horizontally?

- Centrifugal pump: centrifugal pump is a centrifugal force on the impeller rotates to transport liquid pump. Centrifugal pumps use the impeller to rotate and cause centrifugal motion of the water to work. The pump before starting to pump shell and the water pipe filled with water, and then start the motor, the pump shaft to drive the impeller and water do high-speed rotation, centrifugal water movement, was thrown to the outer edge of the impeller, the pressure water pipeline flow through the volute pump into the pump shell.

- Q:What is the function of a submersible pump?Do you have any knowledge about submersible pumps?.

- Important equipment for deep well water extraction. When in use, the whole unit dives into the water. The extraction of groundwater to the surface is water, mine rescue, industrial cooling, irrigation, water lifting, ship ballast, also can be used in fountain landscape, hot water submersible pump for hot spring bath, but also can be applied to the extraction of groundwater from wells, can also be used in rivers, reservoirs, canals and other water projects. The utility model is mainly used for farmland irrigation and water for human and livestock in mountain areas, and can also be used for central air conditioning cooling, heat pump units, cold pump units, cities, factories, railways, mines and site drainage. General flow can reach (10m3~650m3) per hour, head up to 1500 meters.

- Q:What are the internal losses in centrifugal pumps? How did they come about?

- Hydraulic loss: the loss of water by friction, eddy, impact, etc in a flow;

- Q:Suction stroke and lift of water pump

- The absorption process is also called the "largest self-priming height" (also can be understood as "the degree of self suction). Micro pumps do not add water at the circumstances, can automatically water suction pump up the maximum height (the vertical distance from the pump to be pumped from the mouth of pumping liquid).Generally lower than the water pump positioned equal when there is self-priming pump required capacity. For example, outdoor tourism, need to extract the water in the river, with the best micro pump self-priming ability (impossible to people ran to the river water inlet pipe with water. It) or pumping the liquid corrosion, easy to add water and so on occasions.

- Q:Why should I pump the pump before starting the centrifugal pump?

- 1., if it is backward flow, it is not pumping;2., if the pump is installed underwater (such as submersible sewage pump), it is not pumping;3. pump is for installation in the form of suction. If no diversion irrigation pump, then the pump is full of air quality, air density is less than water, the pump will not be inside the gas out, the pump pressure will not be far less than the atmospheric pressure, the water will not be pressed into the pump to pump through irrigation formed inside the closed environment, the pump will start water out will cause local vacuum, entrance external water pressure into the pump is in inside and outside differential pressure, complete water movement. (vacuum water diversion is directly through the vacuum pump pumping the air in the pump, resulting in internal and external pressure difference, the external water pressure in the internal and external pressure is press into the inlet of the pump. The principle is the same as the pump. A standard atmosphere of =10m water column.)

- Q:Because the water pressure of the booster pump is not enough, it can not work automatically. It can only be operated by hand. It is inconvenient to use.

- The worst case is that the pump is not automatic when it leaves the factory, and no one can say whose product is 100%.But there may be automatic control of this piece, not debugging (this depends on the specific product manual or manufacturer)

- Q:Types and differences of pumps

- Classification and working principle of pump by structureClassification of pumpsInvolved pump standard product types are also very much, a centrifugal pump, metering pump, screw pump, reciprocating pump, hydraulic pump, submersible pump, oil pump, water pump, pressure test pump, vortex pump, cryogenic pump, vacuum pump, roots pump, molecular pump, gear pump, mud pump, corrosion-resistant pump deep well pump, water pump, mixed flow pump, axial flow pump, boiler feedwater pump, liquid pump, injection pump, chemical pump, pump plugging and no leakage pump, plastic pump, fire pump and so on, there are many. Its name is divided according to some conventional classification methods such as pump vane pump volume, pump etc., some are divided by purpose such as sewage pump, pump and other health, some names are more random as diffusion pump, liquid nitrogen pump. As long as the production of this product, with standard requirements, through a certain application and approval procedures may produce a new The standard, but sometimes the content also has a repeated cross, quite. The domestic and foreign standards, the domestic standard is more than the number of foreign standards. In general, such as centrifugal pumps are widely used, the production history of the pump more standard (total standard centrifugal pump up to more than 100). As new standard pump leakage pump this rapid development is relatively small. This paper introduces the structure and working principle of the pump according to the classification of the

- Q:If you use an ordinary 15W submersible pump, put it in the tank, if the leakage, the fish will hang it?

- What will happen then? The aquarium glass is an insulator. The water in the fish tank has the same potential as the live wire, and the fish is like a bird standing on the fire line. No electricity flows through their bodies, so they won't get electrocuted. But if you put your hands into the water, you will get an electric shock, because the line voltage through the water, then your body and the earth to form a loop, current flowing through your body you will get (of course, if you stand on the insulator does not get an electric shock)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

QB Series Peripheral Pumps with Brass Impellers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 400 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products