Q41(QHK)160 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

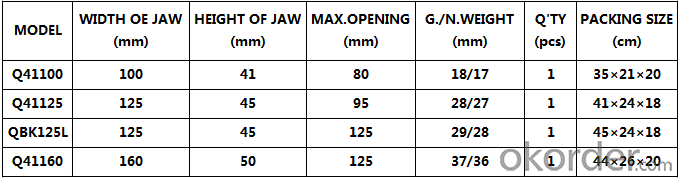

Q41(QHK) SeriesMachine Vice

Performance and character:

1. It adopts the high-quality cast irons.

2. Both parallelismand verticality about the two jaws are 0.025mm/100mm.

3. The vice can beadjusted and locked at random from the horizontal position to the verticalposition (0°-90°)with swiveling base being rotated 360°.

4. It can be widelyused for processing all kinds angels of surface, slots and holes.

- Q:Several basic USES of bench vice

- Essential tool vise for fitter, and fitter for the name of the source, because the bench most of the work is done on the vise, such as saws, file, the chisel, and the components of the assembly and disassembly.

- Q:Do you use a hammer to hit the handle with a clamp?

- The following statement is true (A) A. use A hammer to hit the handle when clamping the workpiece with A vice B. saw a blade tightening with two fingers to tighten the butterfly nut. It feels hard to pull the saw blade In order to increase the efficiency of sawing and cutting, the force should be applied properly when pulling the handsaw The iron filings of the vice of a vice, which can be blown off by the mouth or by hand

- Q:The bench vice is used by the fitter to have which two kinds

- Tips for using bench vice: (1), and clamping workpiece elastic to appropriate, can only use hand tight, but cannot use power tools strength, one is to prevent the screw and nut and clamp suffering damage, the second is to prevent bad surface. (2) in the case of strong work, the force should be fixed in the direction of the clamp, so as not to increase the load of the clamp and screw and nut, and affect its service life. (3) it is not possible to knock on the smooth surface of the active tongs to prevent damage to the fit of the clamp. (4) the surface of activities such as screw and nut should be cleaned and lubricated regularly to prevent rust

- Q:Who has a parts drawing and assembly diagram for a vice?

- I hope I can help you. Learning ug is a problem, it can be sent to the problem supermarket of abcug BBS, there are more people to answer with you.

- Q:The structure of a vice

- The screw is mounted on an active tongs, which can be rotated, but not moved, and fitted with the screw nut mounted inside the clamp. When the handle is moved to rotate the screw, it can be used to move the clamps to move the shaft of the clamps, which can be tightened or relaxed. The spring is fastened to the screw with a baffle and open pin, which is used to loosen the screw and allow the active clamp to exit in time. The clamp is fitted with steel tongs and screws fixed with screws.

- Q:What should be noticed using a bench vice?

- Do not knock on the active clamp and smooth surface. (4) the surface should be cleaned and lubricated regularly to prevent rust.

- Q:How to find a positive two vice

- Recommended to directly purchase side-by-side vise, because the vice of this style guide is high, it is convenient to use, whether you are using several, and each can be used independently, and can be installed to the machine tool worktable by side.

- Q:All of the double force vice is designed with the same high design?

- It's national The model of machine vice is based on the standard of one machine, the type of machine tool accessories. 160 - the main parameter jaw width 160 mm B - type codenamed rotary machine with vice Q - the codename machine USES vice

- Q:How do milling machine tongs correct

- The bed table and the xoxen milling machine are the base of the vice clamp, and the tongs are fixed to the xoxen milling machine with the T type nut.

- Q:What is the industry, what field?

- Vice is generally used in mechanical processing industry, divided into two kinds of machine with vice and vise, the former is used for machining on the machine tool clamping for processing parts, which is installed on the bench work clamping for processing parts, so that the bench manual operation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Q41(QHK)160 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords