Q41(QHK)100 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

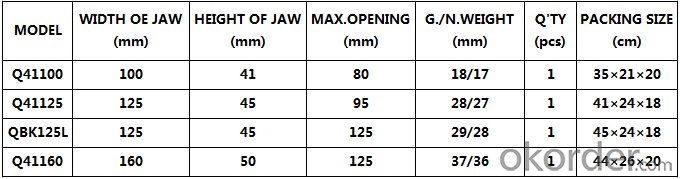

Q41(QHK) SeriesMachine Vice

Performance and character:

1. It adopts the high-quality cast irons.

2. Both parallelismand verticality about the two jaws are 0.025mm/100mm.

3. The vice can beadjusted and locked at random from the horizontal position to the verticalposition (0°-90°)with swiveling base being rotated 360°.

4. It can be widelyused for processing all kinds angels of surface, slots and holes.

- Q:How to calibrate the CNC milling machine tongs

- If you pass the first two steps, you should check the vice jaw, cleanliness, flatness, injury, and parallel to the school watch. In addition, the size of the pincers is small, the size of the workpiece is large, and the clamp size is large, and the clamp is more reliable.

- Q:How do you beat the sink hole of the pincers with two screws, with a drill or a milling cutter

- There are two types of options for processing a processing center: One. Drill holes, drill holes, reamer drills, reamer, etc. 2. Milling hole, the use of two or 90 ° right-angle milling cutter milling machining cutter: For small holes such as 30mm in diameter, you can use a double-edged milling cutter for processing. A small blind hole can also be used for a two-blade milling cutter. Small waist type hole, the most reasonable with two-edge milling cutter, drill down to depth first, and then cross the knife. (the large waist type hole will be drilled with a bit and then used to cut the hole to the waist.) Using the 90 ° Angle cutter will have to use milling spiral interpolation, the premise is tool must be smaller than the pore size, all kinds of macroporous, sink holes, waist type hole, ellipse, etc this method processing; There are many other special ways to process the outside of a CNC machine. For example, the perforation of the barrel of the gun, the forming of the shaft of the barrel in the barrel of the barrel, the forming hole, the grinding hole, the rolling hole, the honing hole, Micro-hole processing of the laser threshold, a type of non-circular hole machining based on electromagnetic drive, etc.

- Q:Is there a god who is good at drawing mechanical drawings?

- On the tongs, such as saw, file, chisel, and assembly and disassembly of parts. Installed on the bench, the width of the tongs is the calibration specification. Common specifications range from 75mm to 300mm. Use of bench vice: the machine is on the workbench, which can be used to clip the workpiece, which is a necessary tool for the fitter workshop.

- Q:What is the meaning of 1/8-3 of the tongs in the pipe

- 3 is 3 inches, 1/8-3 is 1/8 to 3 inches.It can be covered in a tube of 1/8-inch to 3-inch.

- Q:One: what is a heavy bench vice? 2: what is the characteristic of heavy bench vice? What's the performance? What is it for?

- Heavy bench vice is the width of the tongs. Common specifications from 150mm to 300mm bench vice. Bench vice, also known as vice, is a common fixture for holding the piece. The equipment is used on the workbench for the workpiece, which is a necessary tool for the fitter workshop. The rotary clamp can rotate to make the workpiece rotate to the appropriate position. Essential tool vise for fitter, and fitter for the name of the source, because the bench most of the work is done on the vise, such as saws, file, chisel and components of the assembly and disassembly. Installed on the bench, the width of the tongs is the calibration specification. Common specifications range from 75mm to 300mm. Use of bench vice: the machine is on the workbench, which can be used to clip the workpiece, which is a necessary tool for the fitter workshop.

- Q:The working principle of machine vice

- Provisions of clamp body can be installed on the machine working table, function frame, using a wrench, eight screw rotating parts can drive the nut for around 9 parts move, because the helix has two movements:

- Q:What is the commonly used workpiece in milling machine

- Parallel-jaw vice parallel-jaw vice has great versatility and economy, is suitable for smaller square workpiece clamping:) nc milling machine commonly used parallel-jaw vice, often using mechanical screw, pneumatic or hydraulic clamping way.. The tongs of the pincers can be made in various forms and different forms of tongs, which can be used to enlarge the use of the machine. The various forms of the pincers' jaws. Using flat pliers clamping workpiece, according to the first of the artifacts the high precision of cutting height within the flat pliers mat parallel mat iron, in order to make sure. Won't produce in the process of cutting workpiece moving; The second is to find the right of the pincers to ensure that the tongs of the pincers are parallel or perpendicular to the direction of the main shaft cutter. Parallel-jaw vice jaw's alignment method, the indicator with the magnetic table fixed on the spindle, indicator contact contact jaw, along the direction parallel to the jaw moving axis, according to the using readings tongbang tapping parallel-jaw vice adjustment, to ensure that the jaw and parallel or vertical axis direction.

- Q:How to position the pongs

- Flat vice of the base, there is a groove, groove in the two ends of the each have a positioning block, using positioning, the positioning block into the workbench T slot, the vise base location can be completed. Because the vise has a back wheel, first use owe is correct position of the jaw, can in the clamp mouth with a long flat plate, dial indicator adsorbed on the bed, dial indicator first come into contact with the plate, pull the workbench check parallel-jaw vice, parallel, finally fixed fastening screws.

- Q:How to fix the bench vice of the bench bench

- There are three screw holes under the bench vice. You drill three holes in the bench with the electric drill, and then you fix it with a screw.

- Q:What is the width of the tongs? Is it the same thing?

- After the clamp is closed, the length of the closure is the width of the tongs. The length of the length of the tongs that are closed to the mouth is the length of the opening.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Q41(QHK)100 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products