Q345 U shaped Channel Steel Hot Rolled Channel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Q345 U shaped Channel Steel Hot Rolled Channel

Main Structure of Hot Rolled Channel

| 1.Product size | Size : 5#--40# | ||||

| 2.Product length | Lengths : 6m--12m | ||||

| 3.product standard | Standard : GB, ASTM, JIS, DIN | ||||

| 4.product Grade | Grades : Q235B, Q345B, SS400 | ||||

| 5.Application | Used or building structures, vehicle | ||||

| manufacturing and other industrial structures | |||||

| 6.Customized requirement | Can produce special specification products | ||||

| as per our customers' requirement | |||||

| 7.Delivery time | 15-30 days after recieve the LC or pre-paid | ||||

| 8.Detail Package | Bundles, seaworthy wooden cases with or without | ||||

| edge protector, steel hoop and seals, or as per | |||||

| customers' requirements | |||||

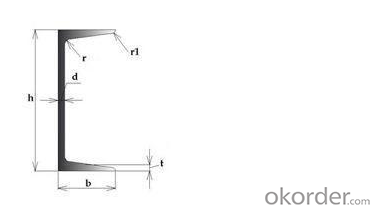

Drawings And Detail Datas (help to know more detail information)

Specification:

Specification | h | b | d | t | Cm2 | (kg/m) |

5 | 50 | 37 | 4.5 | 7 | 6.93 | 5.44 |

6.3 | 63 | 40 | 4.8 | 7.5 | 8.45 | 6.63 |

8 | 80 | 43 | 5 | 8 | 10.24 | 8.04 |

10 | 100 | 48 | 5.3 | 8.5 | 12.74 | 10 |

12.6 | 126 | 53 | 5.5 | 9 | 15.69 | 12.37 |

14a | 140 | 58 | 6 | 9.5 | 18.51 | 14.53 |

14b | 140 | 60 | 8 | 9.5 | 21.31 | 16.73 |

16a | 160 | 63 | 6.5 | 10 | 21.95 | 17.23 |

16 | 160 | 65 | 8.5 | 10 | 25.15 | 19.74 |

18a | 180 | 68 | 7 | 10.5 | 25.69 | 20.17 |

18 | 180 | 70 | 9 | 10.5 | 29.29 | 22.99 |

FAQ:

How's your service?

A:1. Offer customers 24/7 service, whenever you need us, we are always here for you.

2. Immediate response. Your any inquiry will be replied within 24 hours.

3. Support small order quantity, for the first time cooperation customers, we can send you less quantity for trial order.

4. Support third party inspection company to inspect and check the quality and quantity before delivery.

Picture:

- Q:Can stainless steel angles be used in the textile industry?

- Yes, stainless steel angles can be used in the textile industry. They are commonly used for various applications such as fabricating machinery frames, conveyor systems, and support structures. Stainless steel's corrosion resistance and durability make it an ideal material for use in textile manufacturing processes. Additionally, stainless steel angles provide stability and strength, ensuring the reliability and longevity of textile machinery and equipment.

- Q:What are the standard sizes of stainless steel angles?

- The standard sizes of stainless steel angles vary, but commonly range from 25mm x 25mm to 100mm x 100mm in dimensions.

- Q:What are the different types of stainless steel angles connections?

- There are several types of stainless steel angle connections, including welded connections, bolted connections, and adhesive connections. Welded connections involve joining the angles by melting the metal and allowing it to solidify, creating a strong bond. Bolted connections use bolts and nuts to secure the angles together, providing a removable and adjustable connection. Adhesive connections utilize specialized adhesives that bond the angles together, offering a clean and aesthetically pleasing joint.

- Q:What are the bending capabilities of stainless steel angles?

- Stainless steel angles have moderate bending capabilities due to their high strength and rigidity. However, the exact bending capabilities can vary depending on the specific grade and thickness of the stainless steel angle. It is important to consider factors such as the angle's dimensions, the bending method used, and the desired radius of the bend when determining the bending capabilities of stainless steel angles.

- Q:What are the different types of connections used with stainless steel angles in construction?

- There are several different types of connections that can be used with stainless steel angles in construction. Some of the most common types include: 1. Welded connections: This is one of the most common methods of connecting stainless steel angles. It involves welding the angles together using a welding process such as MIG or TIG welding. Welded connections provide a strong and durable connection that can withstand heavy loads and stresses. 2. Bolted connections: Another common method is to use bolts to connect the stainless steel angles. This involves drilling holes through the angles and using bolts and nuts to secure them together. Bolted connections are easier to disassemble and modify, making them a popular choice for temporary structures or situations where adjustments may be needed. 3. Riveted connections: Riveting involves using rivets to join the stainless steel angles together. This method is commonly used in situations where welding or bolting may not be feasible, such as in areas with limited access or where heat distortion is a concern. Riveted connections provide a strong and reliable connection, but they can be time-consuming and require specialized tools. 4. Adhesive connections: Adhesive bonding is sometimes used to connect stainless steel angles in construction. This involves using high-strength adhesive or epoxy to bond the angles together. Adhesive connections can be a good option for situations where drilling or welding is not desired, or for joining dissimilar materials. However, they may not be as strong as other connection methods and may require regular maintenance and inspection. It is important to consider the specific requirements of the construction project and consult with a structural engineer or other qualified professionals to determine the most appropriate type of connection for stainless steel angles.

- Q:Are stainless steel angles resistant to acids and alkalis?

- Yes, stainless steel angles are resistant to both acids and alkalis.

- Q:How does stainless steel angle perform in coastal or marine environments?

- Stainless steel angle performs exceptionally well in coastal or marine environments due to its high resistance to corrosion and rust. The presence of chromium in stainless steel forms a protective layer that prevents the metal from corroding when exposed to saltwater, humidity, and other harsh elements commonly found near the coast. This makes stainless steel angle a durable and long-lasting option for various applications in these environments.

- Q:What are the advantages of using stainless steel angle?

- There are several advantages of using stainless steel angle in various applications. Firstly, stainless steel is highly resistant to corrosion, making it ideal for use in environments where exposure to moisture, chemicals, or harsh weather conditions is a concern. This corrosion resistance helps to extend the lifespan of stainless steel angle, reducing the need for frequent replacements and saving on maintenance costs. Secondly, stainless steel angle offers excellent strength and durability. It has a high tensile strength, allowing it to withstand heavy loads and pressure. This makes it suitable for structural applications where strength and stability are paramount, such as in construction, industrial machinery, and transportation. Moreover, stainless steel angle has an attractive appearance, providing a polished and modern look to any project or application. Its sleek and shiny surface is easy to clean and maintain, making it a popular choice in industries that require hygienic conditions, such as food processing, pharmaceutical, and medical applications. Additionally, stainless steel angle is highly versatile and can be easily fabricated or modified to suit specific requirements. It can be welded, cut, bent, and formed into various shapes and sizes, allowing for a wide range of design possibilities. This versatility makes stainless steel angle suitable for a wide range of applications, including architectural projects, furniture manufacturing, and decorative purposes. Lastly, stainless steel is a sustainable and environmentally friendly material. It is fully recyclable, meaning it can be repurposed or reused without losing its properties. This reduces waste and contributes to a more sustainable and circular economy. Overall, the advantages of using stainless steel angle include corrosion resistance, high strength and durability, attractive appearance, versatility in fabrication, and sustainability. These qualities make stainless steel angle a reliable and cost-effective choice for a wide range of applications across various industries.

- Q:How do stainless steel angles perform in corrosive gas environments?

- Stainless steel angles demonstrate remarkable resistance to corrosion in various environments, including those with corrosive gases. The presence of chromium in stainless steel forms a thin layer of passive oxide on the surface, which serves as a protective barrier against corrosion. This oxide layer remains stable and self-repairs, offering exceptional resistance to gases like sulfur dioxide, hydrogen sulfide, and chlorine. When it comes to corrosive gas environments, stainless steel angles outperform other materials, displaying excellent resistance to pitting corrosion, stress corrosion cracking, and general corrosion. This makes them the preferred choice in industries such as chemical processing, petrochemical, oil and gas, and marine. The specific grade of stainless steel used in the angles also significantly affects their performance in corrosive gas environments. Grades such as 316 and 304 stainless steel are commonly used due to their high resistance to corrosion. These grades contain additional elements like molybdenum, which further enhances their ability to withstand corrosive gases. Nevertheless, it is important to remember that even stainless steel angles can be vulnerable to corrosion under extreme conditions. Factors like extreme temperatures, high concentrations of corrosive gases, or prolonged exposure to aggressive chemicals can potentially impact their performance. Therefore, it is crucial to carefully select the appropriate grade of stainless steel and maintain and clean them properly to maximize their resistance to corrosion in gas environments.

- Q:What are the weight calculations for stainless steel angles?

- The weight calculations for stainless steel angles depend on the dimensions and density of the specific angle. The weight can be calculated by multiplying the length of the angle by the thickness and width, and then multiplying the result by the density of stainless steel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Q345 U shaped Channel Steel Hot Rolled Channel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords