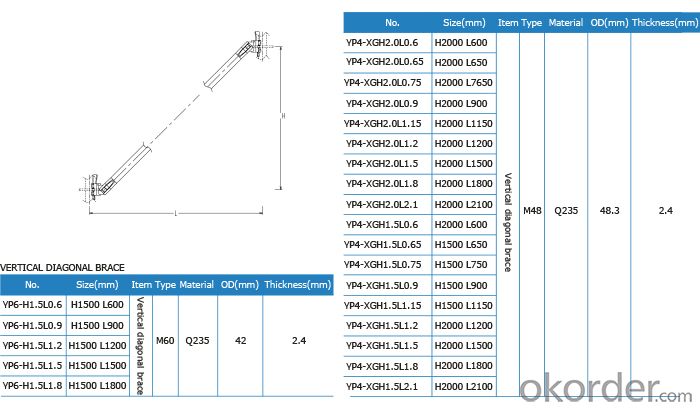

Q235 Ringlock Diagonal Brace 48*2.4-3.25mm with L1200*H1500 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Q235 Ringlock Diagonal Brace 48*2.4-3.25mm with L 1200*H1500

Material :Q235/Q345 carbon steel

Surface treatment :Hot dip galvanized

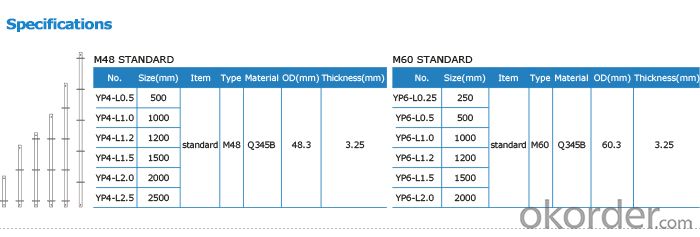

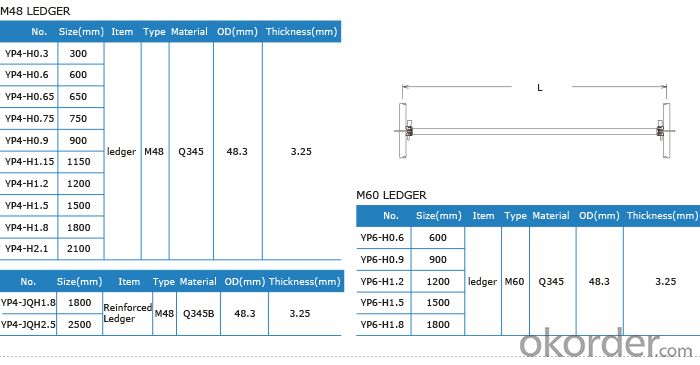

Length :H1500L1200, H1500L1500, H2000L1500, H2000L1800

Thickness :2.4MM/2.5MM/2.75MM/3.0MM/3.25MM

Descriptions of Q235 Ringlock Diagonal Brace 48*2.4-3.25mm with L 1200*H1500

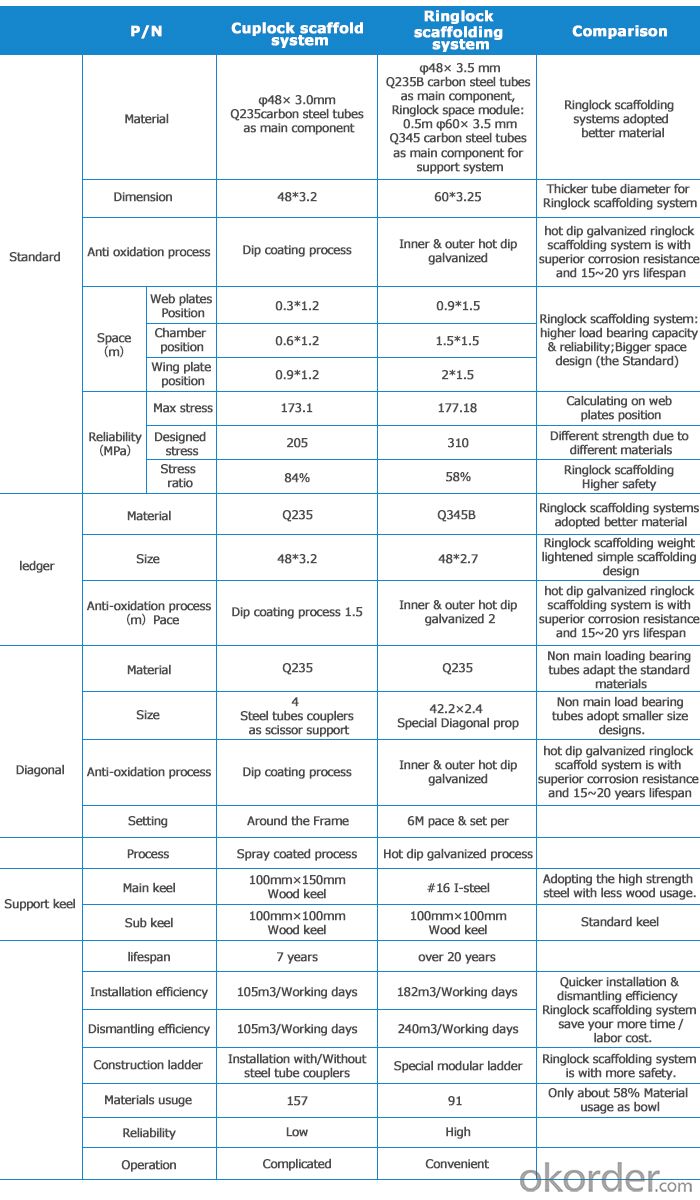

The ringlock Scaffolding and ringlock support system are popularly used in building construction, outside form, cast - in - situ beam, formworks support, canopy frame, bridge & tunnel, stage construction applications and welcomed by building construction companies, construction & decoration companies, leasing companies, media & advertising companies and other users。

Our patented Ringlock Scaffolding and Ringlock support system with surface galvanizing process provided the buyers with higher safety & benefits. Annual output: 7000 tons.

The strong ringlock scaffold system is with 2~3 times installation & dismantling efficiency higher than the cuplock scaffolding system, but only with half steel usage and 75% investment cost.

Our low cost & high benefits Ringlock Scaffolding System with hot dip galvanized surface treatment are easy to installation & disassembly.

Our Ringlock Scaffolding and Ringlock support system with 200 KN high loading bearing capacity are buyers’ safe & professional choice.

Patented R&D and production single personal installation with a hammer only. Greatly saved the steel usages compared to steel tube with couplers.

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:I plan on playing tennis and doing track and field at school... Im getting the piercing this month and it won't be healed in time to take it out. How can I conceal it or possibly even help it heal faster??

- Well an industrial piercing isn't exactly going to get in your way, just put your hair up in a pony tail so your hair doesn't get snagged on it. I wouldn't suggest trying to cover it with anything though, you'll be putting the piercing at risk of infection from trapping bacteria, especially if you're going to end up sweating.

- Q:What are the requirements for acceptance of external scaffolding? Want to know before

- 5, the level should be closed: the first step, every step or two, covered with planks or hand foot fence, scaffolding to laying along the long, joints should be overlapped in the small bar, do not appear short board. And in between in the pole and the wall every four steps long laying safety bottom fence.

- Q:Should the WWE put John Cena in a triple threat thumbtack scaffold cage of death with New Jack & Necro Butcher?

- They should do that to you, hypocritical bastard . Get a life . Edit: It isn't hypocritical to hate John Cena, it's hypocritical to want to put him in that type of situation . He could most definitely die from that .

- Q:Also what 2 cell populations in the body that don't routinely undergo cell division

- The first one is vague. The answer could be the mitotic spindle. It might be kinetochore microtubules. It might be talking about the kinetchores on the chromosomes instead of the microtubules that attach to the kinetochores. It could possibly even be talking about the centromeres, though to me that seems less likely. Neurons in the adult brain (and mature muscle cells?) do not routinely undergo cell division.

- Q:Write a scaffold method for 743,425 divided by 365EASY 10 points

- use a calculator you punk, nobody writes out division anymore, grab your ti-84 and type it out... there's your scaffold method jerk.

- Q:Construction, outdoor double scaffolding a square meter how many meters of steel pipe and how much?

- Each of the joints is about 5%, which needs to be controlled by the step distance and the vertical rod spacing. Under the construction of the construction of steel tubular scaffold safety technology

- Q:At 16 I took my bros 16 gauge piercing needle and pierced my left cartilage and it didn't hurt at all.... and I have a tattoo as well and I laughed through it. So pain isn't huge when it's a small amount.

- Gosh Industrial do hurt I'm not going to lie. Cartilage piercings don't hurt. But industrials are really hard to take care of. If you can handle pain then get it. They're worth it but they do hurt.

- Q:My mom wouldn't let me get snakebites or cyberbites but she will let me get my scaffold pierced. I know people have different things for pain etc etc I know it will hurt but I want it pierced. So, to someone who has gotten it pierced or knows about it is there anything special you have to do to take care of it or is it just like the ear lobe piercing.

- a million. there is a few discomfort in touch. in simple terms relies upon on the way you cope with it. 2. there is new information that even after years of having the piercing it could nonetheless substitute into contaminated =/ 3. It has a bent emigrate because of the fact of ear strengthen (your ears in no way particularly provide up growing to be). 4. Dont over sparkling it. 5. Its executed with a medium gauge needle. 6. i comprehend in the States that many piercing places won't touch everybody under sixteen inspite of parental consent. there is likewise a many greater that isn't touch a minor (everybody under 18). So i could call around and notice.

- Q:1.How does Pearl react when Dimmesdale calls Hester and herself to mount the scaffold with him?

- The answer can be found in the novel The Scarlet Letter by Nathaniel Hawthorne. Read that and you'll have the answer!

- Q:i got my scaffold piercing 4 days ago and it still hurtsit usually doesn't hurt when nothing touches it, but then with the lightest touch of a finger or anything else, it hurts badly.i just cleaned it with h2Ocean and a q-tip and now it hurts really bad. :|should it not be hurting by now? or is this normal.? if its normal.. how long until it heals/stops hurting like a *****. hah

- use warm water mixed with either sea salt or dial soap you can also use salen solution or H2o ocean spray. it's normal by the 2 or 3 week it should stop hurting

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Q235 Ringlock Diagonal Brace 48*2.4-3.25mm with L1200*H1500 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords