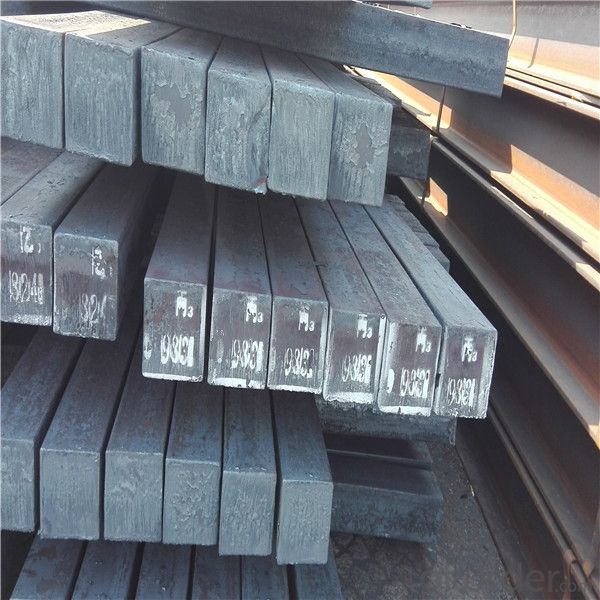

Q235 Q275 square steel billet for sale low price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16800 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Steel billet

(ingot) by cogging or breakdown of semifinished products, is the raw material of all kinds of steel mill.

Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the

shape of rolled products.

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Size :100mm to 165mm

Length:6~12meters

Grade: Q195/Q215/Q235/Q275

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Delivery time: within 45 days after receiving the L/C or advanced T/T payment.

Price term: FOB/CIF/ CFR according to clients requirements

Payment terms: 100%Irrevercable L/C at sight or T/T

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q:How are steel billets used in the production of automotive exhaust systems?

- Automotive exhaust systems rely heavily on steel billets as a vital element. These solid blocks of steel serve as the primary material for manufacturing various parts and components of the exhaust system. To begin the process, the steel billets are heated in a furnace to a specific temperature, which softens the steel and makes it malleable. Once heated, the billets are then molded and shaped into different components of the exhaust system, such as pipes, mufflers, and catalytic converters. The shaping process can be accomplished through hot rolling, cold rolling, or extrusion, depending on the desired shape and properties of the component. Following the shaping process, further treatment is carried out to enhance the strength and durability of the steel billets. This treatment may involve heat processes like quenching and tempering, which improve the steel's hardness, toughness, and resistance to corrosion. These treatments ensure that the exhaust system components can endure the harsh conditions they will encounter, including high temperatures and corrosive gases. Once the steel billets have been shaped and treated, they are assembled and welded together to form the final exhaust system. This involves joining the various components, such as pipes and mufflers, using welding techniques like arc welding or laser welding. These welding processes guarantee secure connections between the components, preventing any leaks or failures in the exhaust system. In summary, steel billets are of utmost importance in the production of automotive exhaust systems as they provide the necessary raw material for shaping and forming the various components. Their exceptional strength, durability, and resistance to high temperatures and corrosion make them an ideal choice for manufacturing exhaust systems capable of withstanding the demanding conditions associated with automotive use.

- Q:How are steel billets used in the production of marine components?

- Steel billets are used in the production of marine components as they serve as the raw material from which various marine parts are manufactured. These billets are heated, shaped, and machined to create components like ship hulls, propeller shafts, engine parts, and other structural elements. By using steel billets, marine manufacturers can ensure the strength, durability, and corrosion resistance required for reliable performance in the demanding marine environment.

- Q:What are the different types of mechanical property testing methods for steel billets?

- There are several different types of mechanical property testing methods used to evaluate the quality and strength of steel billets. These methods include: 1. Tensile Testing: Tensile testing is one of the most commonly used methods to determine the mechanical properties of steel billets. It involves applying a tensile force to a small sample of the billet until it fractures. This test measures the strength, yield strength, elongation, and reduction in area of the material. 2. Impact Testing: Impact testing is used to assess the toughness and resistance to fracture of steel billets. It involves striking a notched specimen with a pendulum or hammer and measuring the energy absorbed during fracture. The results provide information about the material's ability to withstand sudden shocks or dynamic loads. 3. Hardness Testing: Hardness testing determines the resistance of the steel billet to indentation or scratching. Various methods can be employed, such as Rockwell, Brinell, or Vickers hardness testing. The results are often correlated with other mechanical properties, such as strength and ductility. 4. Charpy Testing: Charpy testing is a type of impact test specifically designed to evaluate the notch toughness of steel billets. It involves striking a notched specimen with a pendulum, and the energy absorbed during fracture is measured. This test is particularly useful in assessing the material's behavior under low-temperature conditions. 5. Bend Testing: Bend testing is performed to assess the ductility and flexibility of steel billets. It involves bending a sample around a specified radius until it fractures or shows signs of cracking. This test provides information about the material's ability to withstand deformation without breaking. 6. Fatigue Testing: Fatigue testing is used to evaluate the steel billet's resistance to cyclic loading or repeated stress. It involves subjecting a sample to a varying load, and the number of cycles required for failure is recorded. This test helps determine the material's durability and its ability to withstand long-term stress. These mechanical property testing methods play a crucial role in ensuring the quality and reliability of steel billets for various applications. By evaluating the strength, toughness, hardness, and other mechanical properties, manufacturers and engineers can make informed decisions about the suitability of the material for specific uses.

- Q:How are steel billets used in the manufacturing of marine components?

- Steel billets are used in the manufacturing of marine components as they serve as the starting material for forging, casting, or machining various parts like propellers, hull structures, valves, and shafts. These billets undergo further processing to form the desired shapes and sizes, ensuring the strength, durability, and corrosion resistance required for marine applications.

- Q:How are steel billets used in the production of mining machinery?

- Due to their unique properties and versatility, steel billets play a crucial role in the production of mining machinery. These semi-finished metal forms are made from raw iron ore and undergo a series of heating, rolling, and cooling processes to achieve their final shape and properties. In the manufacturing of mining machinery, steel billets are the primary raw material for various important components. Heavy-duty structural parts, such as frames, chassis, and support structures, require high strength and durability to withstand the extreme conditions and heavy loads in mining operations. Steel billets also serve as the foundation for critical functional components like gears, shafts, and axles. These components are vital for the proper functioning and control of mining machinery, as they transmit power and facilitate movement. Steel billets offer excellent machinability, allowing them to be easily shaped into the complex geometries required for these components. Moreover, steel billets are used to produce wear-resistant parts and components that can withstand constant abrasion, impact, and wear. Cutting edges, buckets, and crusher liners are examples of such components. Steel billets are often alloyed with elements like manganese or chromium to enhance their hardness, toughness, and resistance to wear. In the production of mining machinery, steel billets are also utilized for hydraulic components and systems. Hydraulic cylinders, valves, and pumps are essential for the operation and control of mining equipment. Steel billets provide the necessary strength and integrity to withstand high-pressure hydraulic systems, ensuring reliable and efficient performance. In summary, steel billets are indispensable in the production of mining machinery. They are used to manufacture various structural, functional, and wear-resistant components that are vital for the reliable and efficient operation of mining equipment. The unique properties of steel billets, including their strength, durability, and machinability, make them an ideal choice for withstanding the demanding conditions encountered in mining operations.

- Q:What are the different types of steel billet rolling mill defects?

- During the rolling process of steel billet in a rolling mill, various types of defects may occur. These defects can impact the final product's quality and performance and can have different causes. Some commonly observed defects include: 1. Surface defects: Scratches, cracks, pits, and scale are visible defects that can occur on the surface of the rolled billet. These defects can be caused by improper handling, insufficient lubrication, or excessive rolling pressures. 2. Shape defects: Deviations from the desired shape of the billet, such as bowing, twisting, or excessive tapering, are referred to as shape defects. Uneven cooling, improper alignment of the rolling mill, or incorrect rolling parameters can cause these defects. 3. Internal defects: Internal defects are not visible on the surface but can impact the structural integrity of the billet. Segregation, porosity, and inclusions are examples of internal defects. The presence of impurities in the raw material, improper heating or cooling, or inadequate quality control measures can cause these defects. 4. Dimensional defects: Deviations from the desired dimensions of the billet, such as variations in length, width, or thickness, are called dimensional defects. Improper calibration of the rolling mill, incorrect rolling parameters, or inadequate quality control measures can cause these defects. 5. Metallurgical defects: Metallurgical defects occur due to improper metallurgical processes during rolling. Grain size variations, improper grain flow, or undesirable microstructure are examples of metallurgical defects. Improper temperature control, inadequate alloying, or insufficient heat treatment can cause these defects. To ensure the production of high-quality steel billets, it is crucial for steel billet rolling mills to implement proper quality control measures. Regular inspections, testing, and monitoring during the rolling process can help identify and rectify these defects, thus minimizing their occurrence.

- Q:What are the potential applications of steel billets in the oil and gas industry?

- The oil and gas industry can utilize steel billets in a wide range of ways. These include, but are not limited to, the following: 1. Manufacturing pipes: Steel billets can be used to create pipes that are crucial for transporting oil and gas. The strength and durability of steel make it an excellent choice for constructing pipes that can withstand the harsh conditions of drilling, extraction, and transportation. 2. Creating drill collars: Steel billets can be machined into drill collars, which are heavy steel tubes used in drilling. Drill collars provide weight to the drill string, increasing the force applied to the drill bit. The strength and toughness of steel billets make them suitable for this application, as they can withstand the high torque and pressure exerted during drilling. 3. Making downhole tools: Steel billets can also be used to manufacture a variety of downhole tools used in oil and gas exploration, including stabilizers, reamers, and subs. These tools are crucial for maintaining wellbore stability, clearing obstructions, and enhancing drilling efficiency. The ability of steel billets to withstand high temperatures, pressures, and abrasive environments makes them suitable for these tools. 4. Constructing offshore structures: Steel billets can be used in the construction of offshore platforms, jackets, and other structural components. These structures must withstand extreme weather conditions, corrosive environments, and heavy loads. Steel billets, with their high strength, corrosion resistance, and weldability, are an ideal choice for such applications. 5. Machining equipment and machinery components: Steel billets can be machined into various components and parts for oil and gas equipment and machinery. This includes valves, fittings, flanges, connectors, and other critical components used in drilling rigs, pipelines, refineries, and processing facilities. The versatility and reliability of steel make it a preferred material for such applications. In summary, steel billets have a wide range of potential applications in the oil and gas industry. Their high strength, durability, corrosion resistance, and versatility make them essential in pipe manufacturing, the creation of drill collars and downhole tools, the construction of offshore structures, and the machining of equipment components. Steel billets play a crucial role in ensuring the efficiency, safety, and reliability of oil and gas operations.

- Q:What are the different types of straightening methods used for steel billets?

- There are several different types of straightening methods used for steel billets, depending on the specific requirements and desired outcome. These methods include: 1. Roller Straightening: This method involves passing the steel billets through a series of rollers that apply pressure in various directions to straighten them. The rollers can be adjusted to apply more pressure on certain areas of the billet that may be bent or twisted. 2. Hydraulic Straightening: In this method, hydraulic presses are used to apply pressure on the billets, either in a single direction or in multiple directions. The pressure can be adjusted to achieve the desired level of straightness. 3. Heat Straightening: Heat straightening is a method that involves applying heat to the bent or twisted areas of the steel billets and then using hydraulic or mechanical tools to straighten them. The heat softens the steel, allowing it to be reshaped more easily. 4. Hammering: Hammering is a traditional method of straightening steel billets, where skilled workers use hammers and anvils to manually reshape the billets. This method requires a high level of skill and precision to achieve the desired straightness. 5. Magnetic Straightening: Magnetic straightening is a non-contact method that uses magnetic fields to apply forces on the steel billets and straighten them. This method is often used for smaller and thinner billets, where other methods may cause damage or distortion. Each of these straightening methods has its own advantages and limitations, and the choice of method depends on factors such as the size and thickness of the billets, the degree of straightness required, and the available equipment and resources.

- Q:What are the weight ranges of steel billets?

- The weight of steel billets can vary based on the industry's specific requirements and standards. Generally, steel billets can weigh anywhere from a few kilograms to several metric tons. The weight of a steel billet is determined by factors like its dimensions, intended application, and production process. Smaller steel billets, used in construction or manufacturing, typically weigh between 1 to 10 kilograms. Conversely, larger steel billets, commonly utilized in heavy machinery or infrastructure projects, can weigh anywhere from 10 to 100 metric tons or potentially more. It is important to note that these weight ranges are approximate estimates and may differ depending on the particular industry requirements and production capabilities.

- Q:What are the different types of steel billet quality control tests?

- There are several types of steel billet quality control tests, including dimensional checks, chemical composition analysis, surface inspection, mechanical property testing, and non-destructive testing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Q235 Q275 square steel billet for sale low price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16800 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords