Q235 Galvanized Steel Cuplock Scaffolding System for Large Building Construction CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Q235 Galvanized Steel Cuplock Scaffolding System for Large Building Construction

Type: Heavy Section Steel

Forming: Welding Products

Standard:

Member:

Trademark:

Connection Form:

Carbon Structural Steel:

Residential Wall Structure:

Type of Steel For Building Structure:

Bs1139, En74 Standard:

Export Markets:

Descriptions of Q235 Galvanized Steel Cuplock Scaffolding System for Large Building Construction

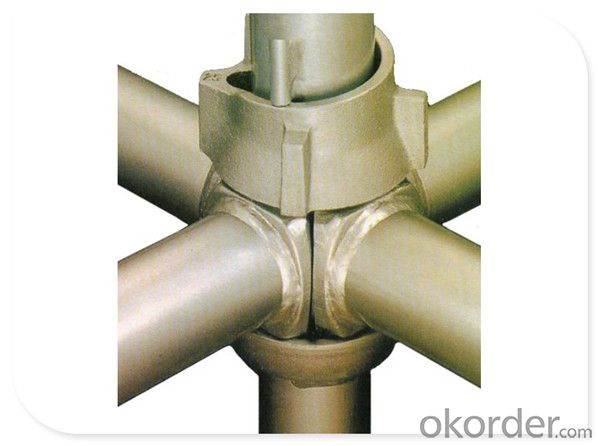

Cuplock is a kind of multi-purpose and versatile modular system scaffolding, suitable for access and formwork support in all types of construction of building & civil engineering projects, offshore projects, etc. This complete galvanized Cuplock system is probably the fastest and most widely preferred scaffolding system. It has flexible erection as straight, curved or circular configuration for both access and support purposes.

Futures of Q235 Galvanized Steel Cuplock Scaffolding System for Large Building Construction

Multi-functional-with the universal joint and fully interchangeable components, the cuplock system can be used in most construction projects for both formwork and access. It is very versatile and diverse. Use in the shipping industries, oil and gas and aviation industries.

Versatile-Verticals are assembled with horizontals and diagonals using secure fixed cup connections. Its versatility has a distinct advantage to conventional scaffolding methods. A positive & ridged connection of four units is achieved in one single action. The cupock system is very cost effective and can be erected safely and quickly.

Time saving-cuplock scaffold is the solution for temporary structures Performance stages. Small teams can erect it safely and quickly.

Economical-Easily assembled system scaffold saves time and labor costs.

Durable-All components are hot dip galvanized and manufactures to international standard.

Easily Stored-Individual pipe elements can be packed in bundles for easy storage and transportation. For returns, material can be packed in steel racks.

The Main Components of Q235 Galvanized Steel Cuplock Scaffolding System for Large Building Construction

Verticals

Description

Material

kg/pc

Article No.

9'10" Vertical 3.00m

Q345 φ48.3×3.2

16.90

SC1001 3000

8'2" Vertical 2.50m

Q345 φ48.3×3.2

14.20

SC1001 2500

6'6" Vertical 2.00m

Q345 φ48.3×3.2

11.60

SC1001 2000

4'11" Vertical 1.50m

Q345 φ48.3×3.2

8.90

SC1001 1500

3'3" Vertical 1.00m

Q345 φ48.3×3.2

6.20

SC1001 1000

1' Vertical 0.50m

Q345 φ48.3×3.2

3.50

SC1001 0500

Horizontals

Description

Material

kg/pc

Article No.

10'0" Horizontal 3.05m

Q345 φ48.3×3.2

11.80

SC1002 3048

9'0" Horizontal 2.74m

Q345 φ48.3×3.2

10.70

SC1002 2743

8'2" Horizontal 2.50m

Q345 φ48.3×3.2

9.80

SC1002 2500

7'0" Horizontal 2.13m

Q345 φ48.3×3.2

8.40

SC1002 2133

6'6" Horizontal 2.00m

Q345 φ48.3×3.2

7.90

SC1002 2000

6'0" Horizontal 1.83m

Q345 φ48.3×3.2

7.20

SC1002 1828

5'11" Horizontal 1.80m

Q345 φ48.3×3.2

7.10

SC1002 1800

5'0" Horizontal 1.52m

Q345 φ48.3×3.2

6.10

SC1002 1524

4'11" Horizontal 1.50m

Q345 φ48.3×3.2

6.00

SC1002 1500

4'1" Horizontal 1.25m

Q345 φ48.3×3.2

5.00

SC1002 1250

4'0" Horizontal 1.22m

Q345 φ48.3×3.2

4.90

SC1002 1219

3'6" Horizontal 1.07m

Q345 φ48.3×3.2

4.30

SC1002 1067

3'3" Horizontal 1.00m

Q345 φ48.3×3.2

4.10

SC1002 1000

3'0" Horizontal 0.91m

Q345 φ48.3×3.2

3.80

SC1002 0914

2'11" Horizontal 0.90m

Q345 φ48.3×3.2

3.70

SC1002 0900

8'0" Horizontal 2.44m

Q345 φ48.3×3.2

9.50

SC1002 2438

1'10" Horizontal 0.57m

Q345 φ48.3×3.2

2.40

SC1002 0600

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:Cantilever scaffold technical disclosure Find satisfaction free speed!!!

- 1, steel pipe:(1) the steel pipe shall have the product quality certificate and inspection report with the outer diameter of 48mm and the thickness of 3.5mm of the steel pipe welded to the steel pipe of 3. Rust must be replaced, not to be used to build the frame.(2) the surface of the steel pipe shall be straight and smooth, and shall not be used for cracks, scars, delamination, dislocation, hard bending, burrs, indentation and deep drawing.(3) anti rust paint for steel pipe. Vertical rod and bar brush yellow rust proof paint, scissors and handrails with red and white tube brush. The maximum quality of each steel pipe shall not be greater than 25Kg. Steel pipe is strictly prohibited.

- Q:The latest JGJ130-2011 construction fastener type steel pipe scaffolding safety technical specifications, schedule A.0.2 what role, how to correctly use it?

- Schedule A.0.2 role: the calculation of scaffolding, the need to calculate the bearing capacity of the scaffolding

- Q:Key points for safety of portal scaffolding

- 4, grade six and above six winds and rain, snow, fog should stop the scaffolding erection, demolition and construction operations.5, during the construction of the following shall not dismantle the rod: 1) cross support, horizontal frame; 2) even wall pieces; 3) reinforcement rods: such as scissors, horizontal reinforcement bar, sweeping pole, sealing rod, etc.;

- Q:Compared to Pankou scaffolding and scaffolding have what distinction, what are the advantages

- 5, Pankou scaffold disassembly do very simple, a person needs only a hammer can do the installation and removal of the entire process. Construction efficiency greatly improved, two construction workers only 1 days to complete the construction site 350m3.

- Q:Does anyone know the name of the song or perhaps have a link to the video if they have seen it on net for example on youtube.?

- aint goin down till the sun comes up

- Q:What's an antonym for the word scaffold?

- Since a scaffold is a bridge/ladder/support used to allow you to span the gap between you and and object you wish to reach, I'd go with barrier.

- Q:Okay so I got a scaffold piercing about 5 days ago now. I've been cleaning it with Claire's piercing stuff. What I do is I pour it onto a little bit of loo roll and squeeze it all out on where the holes are. I have not been twisting it at all, but my friend told me that I should soak it in warm salty water and twist it twice a day. I have no idea what to do now as I have researched it and some people say that I shouldn't twist it because it will drag more bacteria into it and could get it infected. Also I have massive scabs around both ends of the bar, I've tried to pick them off as they are pretty uncomfortable, but it didn't work as they are rock solid, so how do I get these off? I have no idea what to do, my piercer didn't say anything about twisting it just cleaning it twice a day. Oh and if it helps I'm 13:) Thanks. X

- Why are you using Claire's crap? You need to be doing sea salt soaks twice a day for 5-10 minutes each soak with 1/4th of a teaspoon of non-iodized sea salt to 8oz of hot water. Don't twist them as that drags in crust and bacteria and tears up the inside of the piercing. Stop trying to pick stuff off from your ear and go have a reputable piercer check out the scabbing, it could be crust it could be something wrong. If your piercer didn't tell you to do sea salt soaks to keep it clean go to a better piercer.

- Q:Can anyone give a very brief description on all three scaffold scenes in The Scarlet Letter?

- concentration your interest on who's on the scaffold, how they react to the regularly occurring public shaming, and what the reader learns with regard to the character from examining the define of them on the scaffold.

- Q:I've had my scaffolding piercing for about a week now and when cleaning i've just dabbed the hydrogen peroxide and salt water around my ear. However i read that i should be rotating it when cleaning it. Should i rotate it after only a week?

- Do what the piercer told you to do. If they didn't say and you are concerned, ring them and ask. Personally I would say don't; the fluid that the piercing naturally leaks while healing can cake on the bar and dry into tiny but alarmingly sharp lumps. If you push these into the piercing accidentally while turning it it will really really hurt! They can also damage the newly forming tissue, delaying healing and possibly creating excess scar tissue. The bar will move naturally with the movements of your body anyway within the constraints of (sorry if you're squeamish but I can't put it any more delicately) any crusting around the bar. Just keep it clean and keep hair and face products away from it and it should be great.

- Q:three examples of scaffolding, thanks

- Google these 1) Independent scaffold 2) Putlog scaffold 3) Birdcage scaffold

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Q235 Galvanized Steel Cuplock Scaffolding System for Large Building Construction CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords