Q235 Color Steel Step Tile Roll Forming Machine with CE Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Step Tile Roll forming machine

Technical data of step tile roll forming machine

Suitable Material | Q235 color steel sheet;0.4-0.6mm | |

Working speed | About 3.0m/min | |

Step distanc | adjustable according to requirement (>=250mm) | |

Power Requirement | Main motor power: 5.5 Kw(Depend on final design) | |

Hydraulic station power: 5.5Kw(Depend on final design) | ||

Material of forming rollers | No.45 steel, plated with chrome on surface. | |

Material of cutter,pressing die | Cr12 mould steel with quench treatment, HRC58-60 | |

Material of shaft | High quality 45# steel, Dia. is 72mm. | |

Shaft diameter | 72mm | |

Controlling system | Mitsubishi PLC & converter | |

Total weight of machine | About 10500KGS | |

Size of machine installation | About 18m×1.8m× 1.5m (Depend on final design) | |

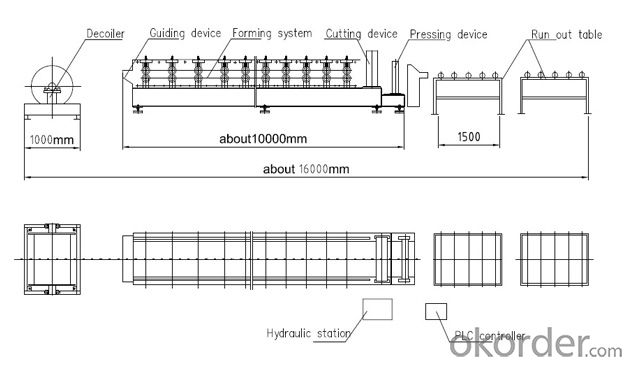

Layout drawing of machine

Our Roll Forming Machine’s advantages

| 1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome . 2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation. 3. Cutter blade: Cr12 mould steel with quenched treatment, long life time. 4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance. 5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction. 6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines. |

- Q:What is the main part of CNC machine tools?

- CNC machine work, do not need workers to directly operate the machine, to control the CNC machine tools,

- Q:What is the advantage of other CNC machine tools compared to other equipment?

- High precision machining, high production efficiency,

- Q:What is the instrument lathe, how to use it?

- Of the production and processing, metal processing industry is the most efficient high-efficiency equipment.

- Q:What is the machine?

- Generally divided into metal cutting machine tools, forging machine tools and woodworking machine tools.

- Q:What is the role of a CNC machine lock switch?

- The control system can logically process a program with control codes or other symbolic instructions and decode it, digitally represented by code, and input to the numerical control device through the information carrier.

- Q:The difference between the lathes 6140, 6240

- In the lathe can also be used drill, reaming drill, reamer, tap, die and knurling tools such as the corresponding processing.

- Q:Lathe C6140 meaning

- And ordinary lathe, 7 said multi-knife and profiled lathe, 8 said wheel, shaft, ingot, roller and shovel lathe, 9 said other lathe.

- Q:What is the difference between CNC machine tools and general machine tools?

- 4, automatic tool changer CNC lathes are used automatic rotary turret, in the process of automatic tool change

- Q:Which machine is the leading machine

- 000410 Shenyang Machine Tool is the world's first machine tool sales in 2011, China's leading position unmatched, before the NC rate is low (about 30%), the two years of high-end force, which lasted five years of successful research Diaoyang CNC system, NC

- Q:What is 16 lathes

- In the lathe can also be used drill, reaming drill, reamer, tap, die and knurling tools such as the corresponding processing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Q235 Color Steel Step Tile Roll Forming Machine with CE Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords