Q13(QB)160 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

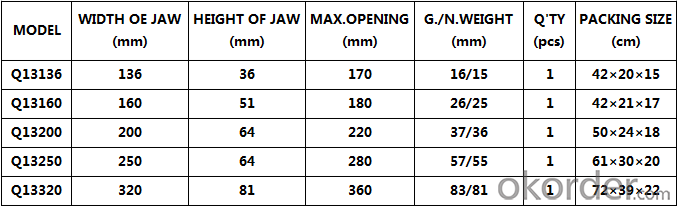

Q13(QB) SeriesMachine Vice

Performance and character:

1. It adopts the high-quality cast irons.

2. Both parallelismand verticality about the two jaws are 0.025mm/100mm.

3. It is widelyused for the milling machine and the drilling machine to process some surface,slots and holes.

- Q:Do you use a hammer to hit the handle with a clamp?

- In theory is not possible, because the length of the handle when the design is according to the stress calculation of screw, but to consider the actual situation, it will do so.

- Q:Can the bench vice clamp the column bar? How to clip

- You can add a pair of live v-shaped pieces if you don't have them regularly If you often need to process the product of a round bar, it is recommended to remove the vice clamp and process the V groove, which will ensure the parallel and clamping of the workpiece

- Q:Is the screw of a vice clamp a silk stick? How do you choose a screw with the same principle? The device requires a general assembly

- Pitch choice: the larger the pitch, the faster the movement tongs, but the smaller the clamps. In contrast, the smaller the pitch, the slower the speed of the tongs, but the greater the clamping force, the typical example is the thread jack. The pitch suggestion is 2mm, that is the handwheel to turn a circle, the activity forceps the mouth to move 2mm

- Q:How does the UG set the motion simulation of the bench vice

- In fact, there is a problem, the screw driver problem, hehe The question that you ask is still a few general, oneself seek some data to see, have specific problem again ask a bit better

- Q:How do you mill a step up the miller's vice

- The pincers of the machine with vice jaw are quenched, and the manufacturing has high shape tolerance control, and it is advised not to break it easily

- Q:The structure of a vice

- The work surface of the tongs is intersected, which makes it difficult to slip when the workpiece is clamped. The tongs are hardened by heat treatment and have good abrasion resistance. Fixed clamp body in a seat, and can rotate axis rotation, when transferred to the requirements of the direction, turn the clamping handle make the clamping screw tightening, can be in the clamping plate under the action of the fixed clamp body is solid and tight. There are three bolt holes in the seat to be fixed with the clamp.

- Q:What is the use of bench vice

- Chinese name: table vice Bench vice Definition: a tool that is installed on a bench with a clamp holder

- Q:How do you beat the sink hole of the pincers with two screws, with a drill or a milling cutter

- There are two types of options for processing a processing center: One. Drill holes, drill holes, reamer drills, reamer, etc. 2. Milling hole, the use of two or 90 ° right-angle milling cutter milling machining cutter: For small holes such as 30mm in diameter, you can use a double-edged milling cutter for processing. A small blind hole can also be used for a two-blade milling cutter. Small waist type hole, the most reasonable with two-edge milling cutter, drill down to depth first, and then cross the knife. (the large waist type hole will be drilled with a bit and then used to cut the hole to the waist.) Using the 90 ° Angle cutter will have to use milling spiral interpolation, the premise is tool must be smaller than the pore size, all kinds of macroporous, sink holes, waist type hole, ellipse, etc this method processing; There are many other special ways to process the outside of a CNC machine. For example, the perforation of the barrel of the gun, the forming of the shaft of the barrel in the barrel of the barrel, the forming hole, the grinding hole, the rolling hole, the honing hole, Micro-hole processing of the laser threshold, a type of non-circular hole machining based on electromagnetic drive, etc.

- Q:The working principle of machine vice

- Provisions of clamp body can be installed on the machine working table, function frame, using a wrench, eight screw rotating parts can drive the nut for around 9 parts move, because the helix has two movements:

- Q:Use of bench vice (simple point)

- When working with the workpiece, only the power of the hand is allowed to handle the handle, not the handle with the hammer, lest the screw, nut, or the clamp be damaged.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Q13(QB)160 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords