PVDF Coated Aluminum Coils 3004 Alloy for Building Materials

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of PVDF Coated Aluminum Coils 3004 Alloy for Building Materials

We normally used PVDF coated aluminum coils 3003 for building materials.

3003 is very good in high strength, corrosion resistance, high weather resistance and other characteristics.

Embossed aluminum sheets have many advantages. Embossing can not only increase thickness of aluminum, but also enhance strength and rigidity of aluminum coils. Embossed & coated aluminum coils look more beautiful and widely used in decorations.

2. Main Features of PVDF Coated Aluminum Coils 3004 Alloy for Building Materials

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

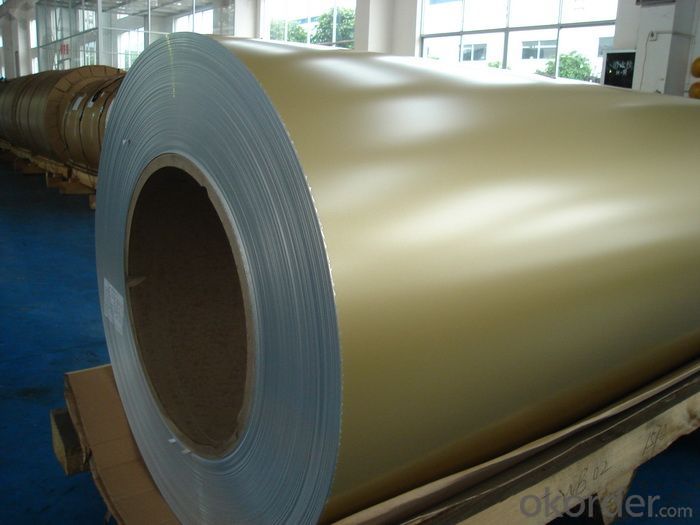

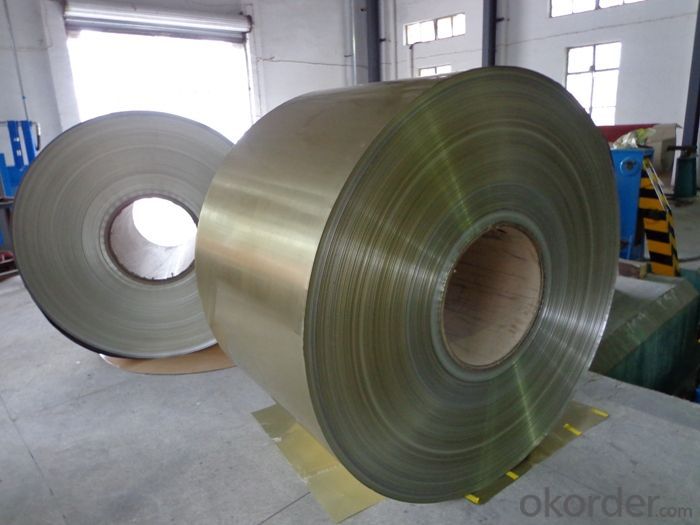

3. PVDF Coated Aluminum Coils 3004 Alloy for Building Materials Images

4. Specification of PVDF Coated Aluminum Coils 3004 Alloy for Building Materials

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:Never put oil in the water. Oil keeps the pasta from absorbing the sauce. Also add a little of the pasta water 3 Tbs. to the sauce. This helps sauce to adhere to pasta. The best remedy for pasta sticking. Use an aluminum stock pot. (tall pan). I don't know why but this works. I have using this stock pot for pasta for 40 years. I've tried stainless, non-stick, etc. they all stick. Except for the Aluminum.1 lb. of pasta, 4 qts. of water. 1Tbs. saltTurn burner to high,keep it therebring to boil then boil for 3 minutes, add 1 TBS salt, add pasta. Stir slowly 2 minutes, until the water boils. Cook tender enough for a fork to cut through but still a little firm

- cool tip. thanks.

- Q:Can aluminum coils be used in the production of beverage cans?

- Certainly, beverage cans can indeed be produced using aluminum coils. Aluminum is the preferred material for manufacturing beverage cans due to its lightweight nature, durability, and ability to maintain the taste and quality of the contents. Typically, aluminum coils are employed in the canning process as they can be readily molded into the desired can shape. These coils are rolled into sheets, which are subsequently cut and transformed into cans. Additionally, aluminum coils possess exceptional heat conductivity, enabling efficient cooling and faster production rates. All in all, aluminum coils play a crucial role in the production of beverage cans and are extensively utilized within the industry.

- Q:Can aluminum coils withstand extreme temperatures?

- Yes, aluminum coils are known for their ability to withstand extreme temperatures. Aluminum has a high melting point of 660.32°C (1220.58°F), which makes it ideal for use in applications that require resistance to heat. Aluminum coils are commonly used in HVAC systems, where they are exposed to both high and low temperatures. They are also used in automotive radiators, where they must endure high operating temperatures. Additionally, aluminum has excellent thermal conductivity, which allows it to efficiently transfer heat away from the coil, further enhancing its ability to withstand extreme temperatures. Overall, aluminum coils are a reliable and durable choice for applications that require resistance to extreme temperatures.

- Q:How are aluminum coils used in the production of automotive heat shields?

- Aluminum coils are used in the production of automotive heat shields as they provide excellent thermal conductivity and heat dissipation properties. These coils are shaped into specific patterns or designs and then attached to the heat shields to effectively reflect and reduce the transfer of heat from the engine or exhaust system to other sensitive components in the vehicle. The use of aluminum coils in heat shields helps in maintaining optimal operating temperatures, enhancing overall performance, and preventing potential damage or fire hazards.

- Q:How are aluminum coils tested for flatness?

- Various methods are employed to test the flatness of aluminum coils, guaranteeing their compliance with the necessary standards. One commonly used approach involves the utilization of a straight edge. In this method, a lengthy and meticulously precise straight edge is placed on the coil's surface. Technicians then visually inspect for any discrepancies or gaps between the straight edge and the coil. The presence of such gaps indicates that the coil is not flat, necessitating further examination. Another technique utilized is the straight edge ruler method. Here, a ruler with a thin and flexible edge is applied to the surface of the coil. By applying gentle pressure, technicians can identify any areas where the ruler fails to fully make contact with the coil, indicating irregularities in its flatness. Advanced methods, including laser or optical techniques, are also employed to assess the flatness of aluminum coils. These methods employ laser beams or optical sensors to measure the surface profile of the coil. The collected data is then analyzed to determine if there are any deviations from the desired flatness. These sophisticated techniques provide precise and accurate results, enabling a more comprehensive evaluation of the coil's flatness. In conclusion, the testing of aluminum coils for flatness is of utmost importance in ensuring that they meet the required standards for a variety of applications. By utilizing a combination of visual inspection, straight edge techniques, and advanced laser or optical methods, manufacturers can guarantee that the coils are flat and devoid of any irregularities that could impact their performance.

- Q:How do aluminum coils contribute to the thermal conductivity of products?

- Aluminum coils play a significant role in enhancing the thermal conductivity of various products. Due to the exceptional thermal properties of aluminum, coils made from this material are highly efficient at transferring heat. The thermal conductivity of aluminum is much higher compared to other common metals, such as steel or copper. This means that when aluminum coils are used in products, they can quickly and effectively transfer heat from one area to another. For instance, in HVAC systems, aluminum coils are often utilized in air conditioning units. When the refrigerant flows through the coils, the aluminum material rapidly absorbs the heat from the surrounding air. This allows for efficient cooling, as the heat is quickly transferred away from the air and expelled, resulting in a more comfortable indoor environment. Similarly, in heat exchangers, aluminum coils facilitate the transfer of heat between two fluids or gases. The high thermal conductivity of the aluminum allows for efficient heat exchange, ensuring that the desired temperature is achieved in a timely manner. Moreover, aluminum coils are lightweight, which makes them more convenient to handle and install in various products. This characteristic is particularly advantageous in industries such as automotive, aerospace, and electronics, where weight reduction is crucial. In summary, aluminum coils significantly contribute to the thermal conductivity of products by efficiently transferring heat due to their high thermal conductivity properties. Their lightweight nature further enhances their versatility and practicality in multiple industries.

- Q:What is the typical tensile strength of aluminum coils?

- The typical tensile strength of aluminum coils can vary depending on the specific grade and temper of the aluminum being used. Generally, aluminum coils have a tensile strength ranging from 30,000 to 75,000 pounds per square inch (psi). However, it is important to note that this range can be narrower or wider depending on the intended application and the specific alloy being used. Additionally, factors such as the thickness and width of the coil may also impact the tensile strength.

- Q:How are aluminum coils processed for specific surface coatings?

- To achieve specific surface coatings on aluminum coils, a series of steps are undertaken. These steps encompass cleaning, pre-treatment, coating application, and curing. Initially, the aluminum coils are subjected to a thorough cleaning process to eliminate any dirt, grease, or contaminants that may impede the coating's adhesion. This typically involves utilizing chemical cleaning agents, rinsing, and sometimes mechanical techniques. Following the cleaning stage, the coils undergo a pre-treatment process, which readies the aluminum surface for optimal coating adhesion. Depending on the specific coating requirements, this pre-treatment may involve chemical etching, conversion coating, or a combination of both. Chemical etching creates a rough surface that enhances the bond between the aluminum and the coating, while conversion coating forms a thin layer that enhances corrosion resistance and adhesion. Upon completion of the pre-treatment, the desired surface coating is applied to the aluminum coils. This can be accomplished using various methods such as coil coating, spray coating, or electrostatic coating. Coil coating is a prevalent technique in which the coil is continuously fed through a coating line, ensuring the even and precise application of the coating material onto the surface. Following the coating application, the aluminum coils undergo a curing process to ensure proper adhesion and hardening of the coating. Curing can be achieved through heat, whereby the coated coils are passed through an oven or furnace at a specific temperature and duration to facilitate cross-linking and curing of the coating material. Alternatively, certain coatings may necessitate UV curing, wherein the coated coils are exposed to ultraviolet light to achieve the desired curing process. In summary, the process of processing aluminum coils for specific surface coatings involves cleaning, pre-treatment, coating application, and curing. This comprehensive approach guarantees that the coils are adequately prepared and coated to meet the desired surface properties and performance requirements.

- Q:I need to draw dot and cross diagrams to explain how they bond, but if the aluminium outer shell has 13 electrons and the oxygen one has 6, how do they all become happy atoms, and all have a full outer shell? please help! thank you.

- Aluminum's outer shell is 3, not 13. 13 is the total number of electrons it has. Looking a the periodic table, Oxygen's usual valance state is -2 as an ion. Aluminum's valance state is always +3. This means that oxygen gains 2 electrons to get a charge of -2 and aluminum lose 3 electrons to get a charge of +3. As for electron configuration, aluminum has 13 electrons in total. 2 e- is in the 1st sublevel. 8 e- is in the 2nd sublevel. That leaves 3 e- left but 3 is not a stable number so aluminum wants to lose those 3 e- to become stable. Oxygen has 8 electrons. 2 e- is in 1st. 6 e- is in 2nd. 6 is not a stable number so oxygen wants to gain 2 more e- to become a full set of 8. Aluminum want to lose 3, Oxygen want to gain 2. We need to balance those. 3 x 2 = 6 2 x 3 = 6 Because Aluminum's usual state is +3, we can have 2 Aluminum atoms bonding. If both lose 3 e-, they both have stable outer shell of 8 (2nd sublevel) and lose 6 e- in total. Oxygen's usual state is -2, but there are 6 e- to gain to oxygen can have 3 atoms bonding. If all 3 atoms receive 2 e- in each, then that's 6 and they're all stable, also at 8 e-. So in order to turn them into happy atom, we need 2 Aluminum and 3 Oxygen to bond together. So the chemical formula is Al2O3 (Aluminum Oxide) *** I'm not very good at explaining, I did the best I can. As for the drawing, I can't do that on the computer. It would have been a whole lot easier if I can though.

- Q:where's the best place to look for aluminum not cans

- TRY A LOCAL HARDWARE STORE

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVDF Coated Aluminum Coils 3004 Alloy for Building Materials

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords