PVC Waterproofing Membrane with Durable Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproofing Membrane with Durable Quality

Product Description of PVC Waterproofing Membrane with Durable Quality:

PVC waterproofing membrane is an excellent high-quality polymer waterproof sheet, made of PVC resin by adding plasticizer, anti-UV agent, anti aging agent, and stabilizer and other processing aids through extrusion and molding. As the highly recommended product by the Ministry of Construction, it is featured by high tensile strength, great elongation, good stability, small shrinkage, low-temperature performances, good resistance to weathering and root

penetration, and long service life.

Features of PVC Waterproofing Membrane with Durable Quality:

1.Long service life and weathering resistance; and the materials can be used for 30 years on the roof and 50 years underground.

2. High tensile strength, great elongation, and small size change during heat treatment.

3. Good low temperature flexibility and adaptability to environmental temperature changes.

4. Good resistance to root penetration. It can be made for green roofs.

5. Excellent resistance to puncture and impact.

6. Convenient for construction (can be welded), solid and reliable, and Eco-friendly.

7. Strong resistance to chemical corrosion, suitable for special occasions.

8. Good plasticity, convenient and quick corner detail treatment. Easy maintenance and low cost.

9.After 2,000 hours of manual weathering verification

Classification of PVC Waterproofing Membrane with Durable Quality:

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Waterproofing Membrane with Durable Quality:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproofing Membrane with Durable Quality:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproofing Membrane with Durable Quality:

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

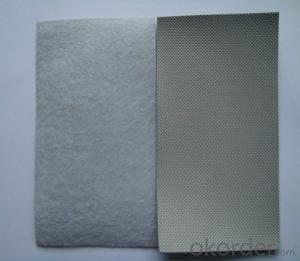

Images of PVC Waterproofing Membrane with Durable Quality:

FAQ of PVC Waterproofing Membrane with Durable Quality:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q:Can a waterproofing membrane be used on zinc surfaces?

- Yes, a waterproofing membrane can be used on zinc surfaces. Zinc is a durable and corrosion-resistant material commonly used in various applications, including roofing and cladding. Applying a waterproofing membrane on zinc surfaces can provide an additional layer of protection against water intrusion and moisture damage. It can help prevent leaks, extend the lifespan of the zinc surface, and maintain its overall integrity. However, it is important to ensure that the waterproofing membrane is compatible with zinc and specifically designed for such applications. It is recommended to consult with a professional or manufacturer to determine the best waterproofing solution for zinc surfaces.

- Q:Can waterproofing membranes be used for planter boxes?

- Yes, waterproofing membranes can be used for planter boxes. Waterproofing membranes provide a protective barrier against moisture, preventing any water leakage that could damage the planter box or surrounding areas. This helps to preserve the longevity and integrity of the planter box, making it suitable for long-term use in outdoor environments.

- Q:Can a waterproofing membrane be applied on top of roofing materials?

- Yes, a waterproofing membrane can be applied on top of roofing materials. It is common practice to install a waterproofing membrane on top of roofing materials to provide an additional layer of protection against water infiltration and extend the lifespan of the roof.

- Q:What are the common mistakes to avoid when installing a waterproofing membrane?

- When installing a waterproofing membrane, it is important to avoid certain common mistakes to ensure its effectiveness and longevity. Some of the common mistakes to avoid include: 1. Inadequate surface preparation: One of the most common mistakes is not properly preparing the surface before installing the membrane. This can include not cleaning the surface thoroughly, not filling cracks or holes, or not removing loose debris. Inadequate surface preparation can compromise the adhesion of the membrane and lead to leaks. 2. Improper membrane selection: Choosing the wrong type of waterproofing membrane can be a costly mistake. Different membranes are designed for specific applications and environmental conditions. It is crucial to select a membrane that is suitable for the specific project requirements to ensure its effectiveness and durability. 3. Inadequate membrane overlap: Properly overlapping the membrane is essential to create a continuous barrier against water infiltration. Inadequate overlap can lead to water seepage and compromise the integrity of the waterproofing system. It is important to follow the manufacturer's instructions regarding the recommended overlap width and ensure proper adhesion between the overlapped sections. 4. Incorrect membrane installation: Improper installation techniques can also lead to issues with the waterproofing membrane. This can include not applying the membrane evenly or not using the correct tools for installation. It is crucial to follow the manufacturer's guidelines and recommendations for installation to ensure a proper and effective waterproofing system. 5. Neglecting proper drainage: Waterproofing membranes should always be accompanied by an adequate drainage system. Failing to install proper drainage can result in water pooling on the surface, which can lead to membrane degradation and potential leaks. It is important to consider the slope and design of the drainage system to ensure efficient water removal. 6. Lack of regular inspection and maintenance: Once the waterproofing membrane is installed, it is important to regularly inspect and maintain it. Neglecting regular inspections and maintenance can lead to issues going unnoticed, such as damage or deterioration, which can compromise the waterproofing system. Regular inspections and timely repairs or maintenance can help prolong the life of the membrane and avoid costly repairs in the future. By avoiding these common mistakes during the installation process and ensuring proper maintenance, you can enhance the effectiveness and longevity of your waterproofing membrane, providing reliable protection against water infiltration.

- Q:Are there any specific safety precautions to consider when installing a waterproofing membrane?

- Yes, there are several safety precautions to consider when installing a waterproofing membrane. Firstly, it is important to ensure that all necessary personal protective equipment (PPE) is used by the installation team. This may include gloves, safety glasses, and appropriate footwear to prevent any injuries or exposure to hazardous materials. Additionally, it is crucial to work in a well-ventilated area to avoid inhalation of fumes or vapors emitted during the installation process. If working in a confined space, proper measures should be taken to ensure adequate ventilation and the use of proper respiratory protection if necessary. Furthermore, it is important to follow the manufacturer's instructions and guidelines for the specific waterproofing membrane being installed. This includes understanding any potential hazards associated with the product, such as flammability or toxicity, and taking necessary precautions to prevent accidents or exposure. Another safety consideration is to ensure that the installation area is properly prepared before beginning the process. This may involve removing any debris, cleaning the surface, and addressing any potential hazards or obstacles that could pose a risk to the installation team. Lastly, it is important to have a designated safety plan in place, including emergency procedures and first aid kits readily available in case of accidents or injuries. Regular safety inspections and monitoring throughout the installation process are also recommended to identify and address any potential safety risks promptly. By following these safety precautions, the installation of a waterproofing membrane can be carried out safely and effectively, minimizing the risk of accidents or injuries.

- Q:Can a waterproofing membrane be applied on both interior and exterior surfaces of a structure?

- Both interior and exterior surfaces of a structure can receive the application of a waterproofing membrane. These membranes are designed to form a barrier that prevents water from infiltrating the structure. Regardless of whether it is applied internally or externally, the membrane serves the same purpose of keeping water out and safeguarding the structure against moisture damage. In the case of basements, crawl spaces, or other areas where water intrusion from the inside is a worry, interior waterproofing membranes are typically utilized. On the other hand, exterior waterproofing membranes are commonly used on foundation walls, below-grade areas, or building envelopes to stop water from seeping into the structure. It is crucial to select the appropriate type of waterproofing membrane based on the specific requirements and conditions of the structure.

- Q:Can a waterproofing membrane be applied in cold weather?

- Yes, a waterproofing membrane can be applied in cold weather. However, it's important to consider the specific product's instructions and limitations, as some membranes may have temperature requirements for proper installation. Additionally, cold weather conditions may affect the curing time of the membrane, so it's crucial to follow the manufacturer's guidelines to ensure a successful application.

- Q:Can waterproofing membranes be used on balconies?

- Yes, waterproofing membranes can be used on balconies. These membranes are designed to provide a protective barrier against moisture, preventing water leaks and damage to the balcony structure. Waterproofing membranes are commonly used in balcony construction and renovation projects to ensure long-lasting water resistance and durability.

- Q:How do waterproofing membranes prevent water leakage?

- Waterproofing membranes prevent water leakage by creating a physical barrier between the structure and the water. These membranes are made of materials that are impermeable to water, such as rubber, PVC, or bitumen. When applied correctly, they form a continuous and seamless layer that prevents water from seeping through cracks, joints, or other vulnerable areas. This barrier effectively stops water from infiltrating the structure, ensuring its protection against water damage and leakage.

- Q:Does a waterproofing membrane require any special precautions during installation?

- Yes, a waterproofing membrane does require special precautions during installation. It is important to ensure that the surface to be waterproofed is clean, dry, and free from any contaminants or loose materials. The membrane should be installed in accordance with the manufacturer's instructions, paying attention to proper overlap and seam sealing. It is also crucial to inspect the membrane for any damage or defects prior to installation. Additionally, proper safety measures should be taken, such as wearing protective clothing and using appropriate tools and equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Waterproofing Membrane with Durable Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords