PVC Waterproofing Membrane for Planting Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproofing Membrane for Planting Roofing

Product Description of PVC Waterproofing Membrane for Planting Roofing:

PVC waterproofing membrane is an excellent high-quality polymer waterproof sheet, made of PVC resin by adding plasticizer, anti-UV agent, anti aging agent, and stabilizer and other processing aids through extrusion and molding. As the highly recommended product by the Ministry of Construction, it is featured by high tensile strength, great elongation, good stability, small shrinkage, low-temperature performances, good resistance to weathering and root

penetration, and long service life.

Features of PVC Waterproofing Membrane for Planting Roofing:

1.Long service life and weathering resistance; and the materials can be used for 30 years on the roof and 50 years underground.

2. High tensile strength, great elongation, and small size change during heat treatment.

3. Good low temperature flexibility and adaptability to environmental temperature changes.

4. Good resistance to root penetration. It can be made for green roofs.

5. Excellent resistance to puncture and impact.

6. Convenient for construction (can be welded), solid and reliable, and Eco-friendly.

7. Strong resistance to chemical corrosion, suitable for special occasions.

8. Good plasticity, convenient and quick corner detail treatment. Easy maintenance and low cost.

9.After 2,000 hours of manual weathering verification

Classification of PVC Waterproofing Membrane for Planting Roofing:

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Waterproofing Membrane for Planting Roofing:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproofing Membrane for Planting Roofing:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproofing Membrane for Planting Roofing:

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

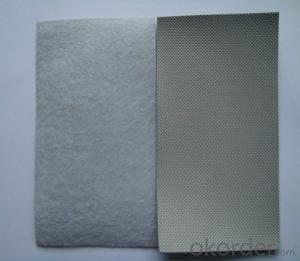

Images of PVC Waterproofing Membrane for Planting Roofing:

FAQ of PVC Waterproofing Membrane for Planting Roofing:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q:Can a waterproofing membrane be applied to vertical surfaces?

- Yes, a waterproofing membrane can be applied to vertical surfaces. In fact, waterproofing membranes are commonly used on vertical surfaces such as walls, foundations, and retaining walls to protect against water infiltration. These membranes are specifically designed to adhere to vertical surfaces and provide a protective barrier against water, preventing moisture from seeping into the structure. The application process typically involves cleaning and preparing the surface, applying a primer if necessary, and then installing the waterproofing membrane using a suitable adhesive or mechanical fastening system. This ensures that the membrane forms a continuous and secure seal, effectively preventing water penetration. Overall, waterproofing membranes offer an effective solution for waterproofing vertical surfaces and are widely used in construction and building maintenance projects.

- Q:Does a waterproofing membrane provide any insulating properties?

- A waterproofing membrane does not offer any insulation. Its main purpose is to stop water or moisture from entering a building or roof. It acts as a protective barrier, preventing damage to the underlying materials. Insulation, on the other hand, is specifically designed to minimize the transfer of heat, sound, or electricity. While both waterproofing and insulation are crucial for maintaining a structure's integrity and functionality, they serve distinct purposes and should not be mistaken for each other.

- Q:Can a waterproofing membrane be used on plaster surfaces?

- Yes, a waterproofing membrane can be used on plaster surfaces. It provides a protective barrier that prevents water penetration and helps to enhance the durability and longevity of the plaster surface.

- Q:Where can waterproofing membranes be used?

- Waterproofing membranes have a wide range of applications across different industries. They are commonly utilized in various settings, including: 1. Building and construction: In the construction industry, waterproofing membranes are frequently employed to safeguard structures like basements, roofs, and foundations from water infiltration and subsequent damage. They effectively shield buildings against moisture-related problems such as leaks, mold formation, and deterioration. 2. Civil engineering: Waterproofing membranes are essential in civil engineering projects like tunnels, bridges, and dams to ensure water resistance and prevent water penetration. By keeping these infrastructures dry and protected, they help maintain their structural integrity. 3. Landscaping: When it comes to landscaping projects, waterproofing membranes are commonly used to prevent water from seeping into the soil and causing erosion. They are particularly useful in retaining walls, garden beds, and underground structures, as they contribute to the stability and longevity of the landscape. 4. Transportation: The transportation industry benefits from the application of waterproofing membranes, especially during the construction of roads, highways, and parking lots. By safeguarding the underlying layers from water damage, which can lead to cracks and potholes, they extend the lifespan of transportation infrastructures. 5. Industrial facilities: Many industrial facilities, such as factories, warehouses, and chemical plants, require waterproofing to protect their structures and equipment from water damage. Waterproofing membranes serve as barriers against water intrusion, preventing corrosion and preserving the longevity of these facilities. In summary, waterproofing membranes are versatile solutions that are indispensable in various sectors where water resistance and protection against moisture-related damages are crucial. They play a critical role in preserving the integrity and longevity of structures and infrastructures, thus preventing costly repairs and ensuring a safe and functional environment.

- Q:Can a waterproofing membrane be used in areas with extreme weather conditions, such as hurricanes or snowstorms?

- Yes, waterproofing membranes can be used in areas with extreme weather conditions, including hurricanes and snowstorms. These membranes are specifically designed to provide protection against water penetration and are built to withstand harsh weather elements. They are often used in construction projects to ensure the durability and longevity of structures in such environments.

- Q:Is a waterproofing membrane suitable for use in areas with high groundwater levels?

- A waterproofing membrane works well in areas where the groundwater levels are high. Its purpose is to stop water from getting in, making it an effective barrier against groundwater. These membranes are usually made from materials like bitumen, PVC, or EPDM, which are extremely resistant to water and can handle a lot of pressure from below. They are built to create a tight seal, keeping water out of buildings or underground areas. Because of this, a waterproofing membrane is the perfect choice for places with high groundwater levels. It can successfully guard against water infiltration and the potential harm it could cause to structures or infrastructure.

- Q:Can a waterproofing membrane be used on asphalt surfaces?

- Indeed, asphalt surfaces can benefit from the application of a waterproofing membrane. These membranes, widely employed in construction, are specifically engineered to safeguard against water infiltration. Their versatility allows for application on diverse surfaces, asphalt included. By applying a waterproofing membrane on an asphalt surface, one can effectively thwart water damage, prolong the surface's lifespan, and safeguard the underlying structures. It is crucial to guarantee the compatibility of the chosen waterproofing membrane with asphalt and to adhere to proper installation techniques in order to achieve the best possible outcome.

- Q:Polyethylene polypropylene waterproofing membrane forming. Secondary molding, what does it mean? How to distinguish?

- The second compound is, first produced or bought from the market polyethylene film, by heating the polypropylene non-woven composite up. This method is not enough heating, non-woven stickers are not strong, heating is too high, the polyethylene film damage, polyethylene plastic through the second heating to speed up his aging. Further, the polyethylene film for secondary compounding, the proportion of the recycled plastic is too high, and the anti-aging property is lowered.

- Q:Can a waterproofing membrane be used for museums or art galleries?

- Yes, a waterproofing membrane can be used for museums or art galleries. It plays a crucial role in protecting valuable artwork and artifacts from moisture damage, mold, and other environmental factors. By creating a barrier against water penetration, a waterproofing membrane helps to maintain the integrity and longevity of the exhibits, ensuring their preservation and preventing any potential harm caused by moisture.

- Q:How does a waterproofing membrane handle temperature fluctuations?

- A waterproofing membrane is designed to handle temperature fluctuations by being able to expand and contract without compromising its effectiveness. It is made of materials that are flexible and can withstand extreme temperatures, ensuring that it remains intact and continues to provide protection against water infiltration.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Waterproofing Membrane for Planting Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords